Are you gearing up for an interview for a Caustic Liquor Maker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Caustic Liquor Maker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

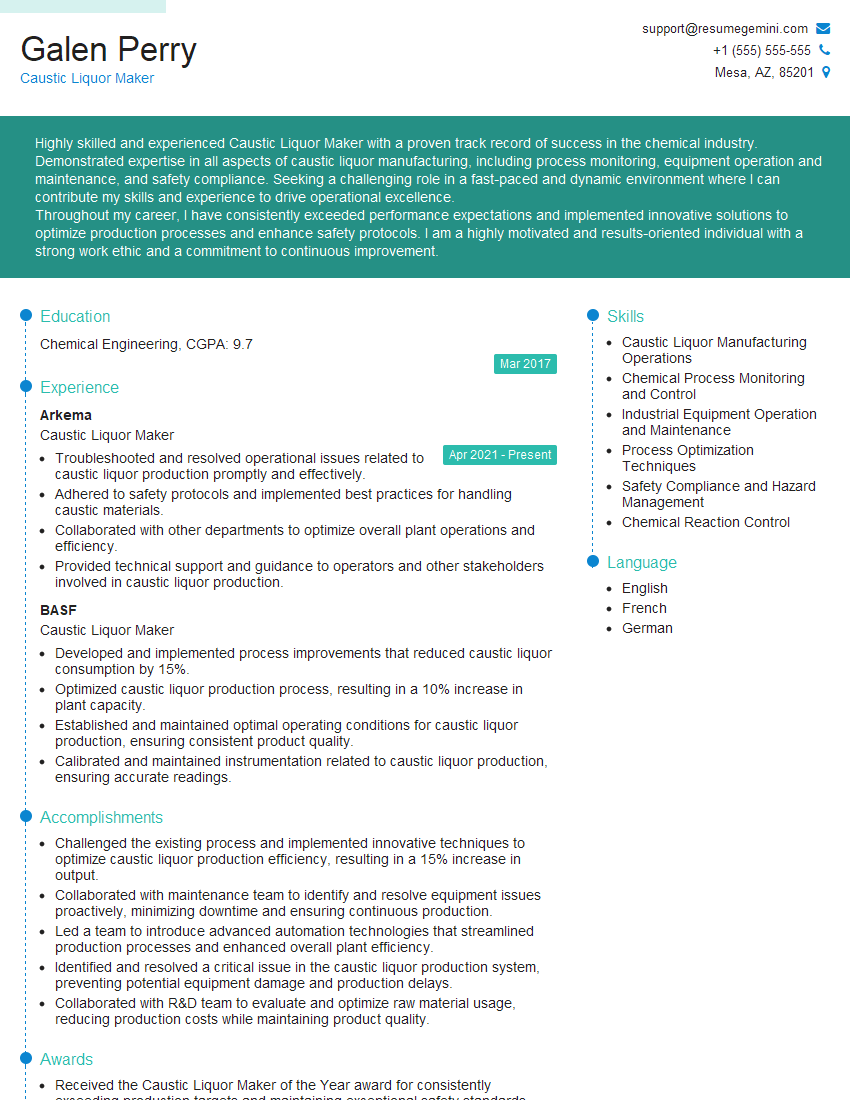

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Caustic Liquor Maker

1. What are the key responsibilities of a Caustic Liquor Maker?

- Operate and maintain caustic liquor-making equipment, including evaporators, crystallizers, and filters

- Monitor and control the chemical composition of caustic liquor

- Troubleshoot and repair equipment problems

- Ensure that caustic liquor meets quality standards

- Follow safety procedures and maintain a clean and organized work area

2. What are the different types of caustic liquor-making processes?

Batch process

- In a batch process, caustic liquor is produced in a series of batches

- The raw materials are added to a reactor and the reaction is allowed to proceed for a period of time

- Once the reaction is complete, the product is removed from the reactor and purified

Continuous process

- In a continuous process, caustic liquor is produced continuously

- The raw materials are fed into the reactor at a constant rate and the product is removed at a constant rate

- Continuous processes are more efficient than batch processes, but they require more complex equipment

3. What are the safety precautions that must be taken when working with caustic liquor?

- Caustic liquor is a corrosive substance and can cause severe burns

- It is important to wear protective clothing, including gloves, goggles, and a face shield

- Caustic liquor should be stored in a cool, dry place

- Spills should be cleaned up immediately

4. What are the environmental regulations that apply to caustic liquor production?

- Caustic liquor production is regulated by the Environmental Protection Agency (EPA)

- The EPA has set limits on the amount of caustic liquor that can be discharged into the environment

- Caustic liquor producers must also comply with local and state regulations

5. What are the quality control procedures that must be followed in caustic liquor production?

- Caustic liquor must meet certain quality standards before it can be used

- These standards include the concentration of caustic soda, the presence of impurities, and the appearance of the product

- Caustic liquor producers must test their product regularly to ensure that it meets these standards

6. What are the common problems that can occur in caustic liquor production?

- The most common problem is the formation of scale on the equipment

- Scale can block the flow of caustic liquor and cause the equipment to overheat

- Other problems include the formation of impurities and the loss of caustic soda

7. What are the maintenance procedures that must be followed to keep caustic liquor-making equipment in good working condition?

- Caustic liquor-making equipment must be inspected regularly and maintained according to the manufacturer’s instructions

- This includes cleaning, lubricating, and replacing worn parts

- Regular maintenance can help to prevent breakdowns and extend the life of the equipment

8. What are the troubleshooting procedures that must be followed if caustic liquor-making equipment breaks down?

- If caustic liquor-making equipment breaks down, it is important to troubleshoot the problem and repair it as quickly as possible

- This may involve checking the electrical connections, the mechanical components, and the chemical composition of the caustic liquor

- Once the problem has been identified, it can be repaired and the equipment can be returned to service

9. What are the future trends in caustic liquor production?

- The future of caustic liquor production is bright

- The demand for caustic liquor is expected to grow in the coming years, driven by the increasing demand for paper, textiles, and other products

- New technologies are being developed to improve the efficiency and sustainability of caustic liquor production

10. What are your strengths and weaknesses as a Caustic Liquor Maker?

- Strengths: I am a highly skilled and experienced Caustic Liquor Maker

- I have a strong understanding of the caustic liquor-making process and I am proficient in operating and maintaining caustic liquor-making equipment

- I am also a team player and I am always willing to help out my colleagues

- Weaknesses: I am sometimes too detail-oriented and I can be a bit of a perfectionist

- I am also not always the most patient person, especially when things are not going my way

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Caustic Liquor Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Caustic Liquor Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Caustic Liquor Makers are responsible for operating and maintaining equipment used to produce caustic liquor, a chemical used in various industries. Their key responsibilities include:

1. Operating and maintaining equipment

Caustic Liquor Makers operate and maintain equipment such as evaporators, crystallizers, and pumps used in the production of caustic liquor. They ensure that the equipment is functioning properly and make necessary adjustments to optimize production.

- Monitoring and adjusting equipment settings to ensure optimal performance

- Performing routine maintenance and repairs to keep equipment in good working order

2. Controlling chemical processes

Caustic Liquor Makers control chemical processes involved in the production of caustic liquor. They monitor and adjust process parameters such as temperature, pressure, and concentration to ensure that the liquor meets quality specifications.

- Maintaining proper chemical balance in the production process

- Analyzing samples of caustic liquor to ensure it meets quality standards

3. Monitoring production

Caustic Liquor Makers monitor production to ensure that it meets targets and quality standards. They keep records of production data and identify any potential problems or inefficiencies.

- Tracking production output and efficiency

- Identifying and addressing production issues

4. Complying with safety and environmental regulations

Caustic Liquor Makers must adhere to all applicable safety and environmental regulations. They wear appropriate personal protective equipment and follow established procedures to minimize risks and protect the environment.

- Following established safety protocols

- Handling chemicals and waste materials safely and responsibly

Interview Tips

To ace an interview for a Caustic Liquor Maker position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some tips:

1. Research the company and the role

Before the interview, it is essential to research the company and the specific role you are applying for. Understand the company’s background, values, and the industry in which they operate. Learn about the key responsibilities and qualifications required for the Caustic Liquor Maker position.

- Visit the company’s website and social media pages

- Read industry news and articles

2. Practice your answers

Take time to practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Prepare examples from your previous work experience that demonstrate your skills and abilities relevant to the job.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

- Focus on highlighting your accomplishments and quantifying your results

3. Prepare questions for the interviewer

Asking thoughtful questions shows your interest in the role and the company. Prepare a list of questions to ask the interviewer, such as “What are the biggest challenges facing the production team?” or “What is the company’s commitment to sustainability?”

- Avoid asking generic questions

- Tailor your questions to the specific role and company

4. Dress professionally and arrive on time

First impressions matter. Dress appropriately for the interview and arrive on time. Be polite and respectful to everyone you meet, from the receptionist to the interviewer.

- Choose clean and pressed attire that is appropriate for the work environment

- Punctuality shows respect for the interviewer’s time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Caustic Liquor Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!