Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Caustic Purification Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

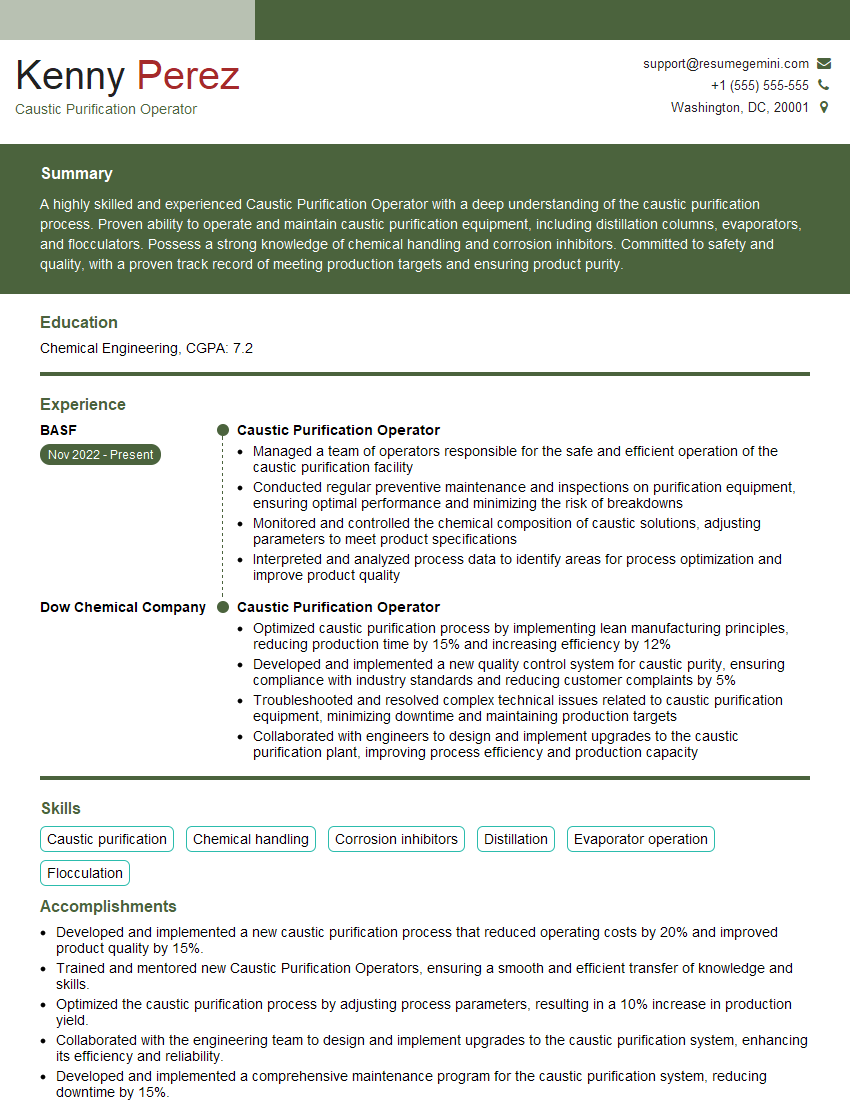

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Caustic Purification Operator

1. Describe the process of caustic purification?

Caustic purification is a process that removes impurities from caustic soda. The impurities can include salts, metals, and organic matter. The purification process typically involves the following steps:

- The caustic soda is first diluted with water to form a solution.

- The solution is then heated to a high temperature, which causes the impurities to precipitate out of the solution.

- The precipitate is then removed from the solution by filtration or centrifugation.

- The purified caustic soda solution is then concentrated by evaporation.

2. What are the different types of caustic purification processes?

There are two main types of caustic purification processes: the lime-soda process and the membrane process.

Lime-soda process

- The lime-soda process is a traditional method of caustic purification that uses lime and soda ash to remove impurities from caustic soda.

- The process involves adding lime and soda ash to the caustic soda solution, which causes the impurities to precipitate out of the solution.

- The precipitate is then removed from the solution by filtration or centrifugation.

Membrane process

- The membrane process is a newer method of caustic purification that uses membranes to remove impurities from caustic soda.

- The process involves passing the caustic soda solution through a membrane, which allows the impurities to pass through while the caustic soda is retained.

- The purified caustic soda solution is then concentrated by evaporation.

3. What are the advantages and disadvantages of the lime-soda process?

Advantages

- The lime-soda process is a relatively simple and inexpensive process.

- The process is effective at removing impurities from caustic soda.

Disadvantages

- The lime-soda process can generate a large amount of sludge, which can be difficult to dispose of.

- The process can also result in the loss of caustic soda, which can increase the cost of the process.

4. What are the advantages and disadvantages of the membrane process?

Advantages

- The membrane process is a more efficient process than the lime-soda process.

- The process produces less sludge and does not result in the loss of caustic soda.

Disadvantages

- The membrane process is more expensive than the lime-soda process.

- The membranes can be damaged by impurities in the caustic soda solution.

5. What are the safety precautions that must be taken when working with caustic soda?

- Caustic soda is a corrosive substance that can cause severe burns.

- It is important to wear protective clothing, including gloves, goggles, and a face shield, when working with caustic soda.

- Caustic soda should be stored in a cool, dry place away from incompatible materials.

6. What is the role of a Caustic Purification Operator?

- The Caustic Purification Operator is responsible for operating the caustic purification plant.

- This includes monitoring the process, making adjustments to the process parameters, and troubleshooting any problems that may arise.

- The Caustic Purification Operator also performs routine maintenance on the equipment.

7. What are the qualifications of a Caustic Purification Operator?

- A Caustic Purification Operator typically has a high school diploma or equivalent.

- The Operator may also have some college coursework in chemistry or engineering.

- The Operator must have experience operating chemical process equipment.

8. What are the key skills of a Caustic Purification Operator?

- Key skills for a Caustic Purification Operator include:

- Ability to operate chemical process equipment

- Understanding of chemical processes

- Troubleshooting skills

- Communication skills

- Teamwork skills

9. What are the career prospects of a Caustic Purification Operator?

- Caustic Purification Operators can advance to positions such as Process Engineer, Production Supervisor, or Plant Manager.

- The Operator may also choose to start their own business.

10. What is the salary range for a Caustic Purification Operator?

- The salary range for a Caustic Purification Operator varies depending on experience, location, and employer.

- The average salary for a Caustic Purification Operator in the United States is around $50,000 per year.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Caustic Purification Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Caustic Purification Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Caustic Purification Operator, you will be responsible for operating and maintaining the Caustic Purification system, including:

1. Monitoring and Controlling the Caustic Purification Process

Ensuring the system is operating within specified parameters to produce purified caustic products

- Monitoring process variables such as temperature, pressure, flow rate, and caustic concentration.

- Adjusting control parameters to maintain optimal operating conditions.

2. Troubleshooting and Maintaining the Caustic Purification System

Identifying and resolving operational issues to ensure smooth operation of the system

- Performing regular inspections and maintenance of equipment.

- Troubleshooting and repairing system components as needed.

3. Sampling and Testing Caustic Products

Ensuring the quality of purified caustic products meets specifications

- Collecting and analyzing caustic samples.

- Maintaining records of test results.

4. Complying with Safety and Environmental Regulations

Ensuring the safe and environmentally compliant operation of the Caustic Purification system

- Following established safety protocols.

- Complying with environmental regulations.

Interview Preparation Tips

To prepare for your interview as a Caustic Purification Operator, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, operations, and the specific requirements of the Caustic Purification Operator role.

- Visit the company’s website and social media pages.

- Review the job description thoroughly.

2. Highlight Your Relevant Skills and Experience

Emphasize your knowledge and experience in operating and maintaining Caustic Purification systems, as well as your troubleshooting abilities.

- Provide specific examples of your work experience.

- Quantify your accomplishments whenever possible.

3. Prepare for Technical Questions

Expect questions about your understanding of Caustic Purification processes and equipment. Review the principles of operation and common troubleshooting techniques.

- Study process flow diagrams and equipment specifications.

- Practice answering technical questions in a clear and concise manner.

4. Demonstrate Your Safety and Environmental Awareness

Show the interviewer that you are aware of the potential hazards associated with Caustic Purification operations and that you are committed to following safety protocols and environmental regulations.

- Highlight your knowledge of safety procedures and environmental regulations.

- Discuss your experience in implementing safety measures.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Caustic Purification Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.