Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Caustic Room Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

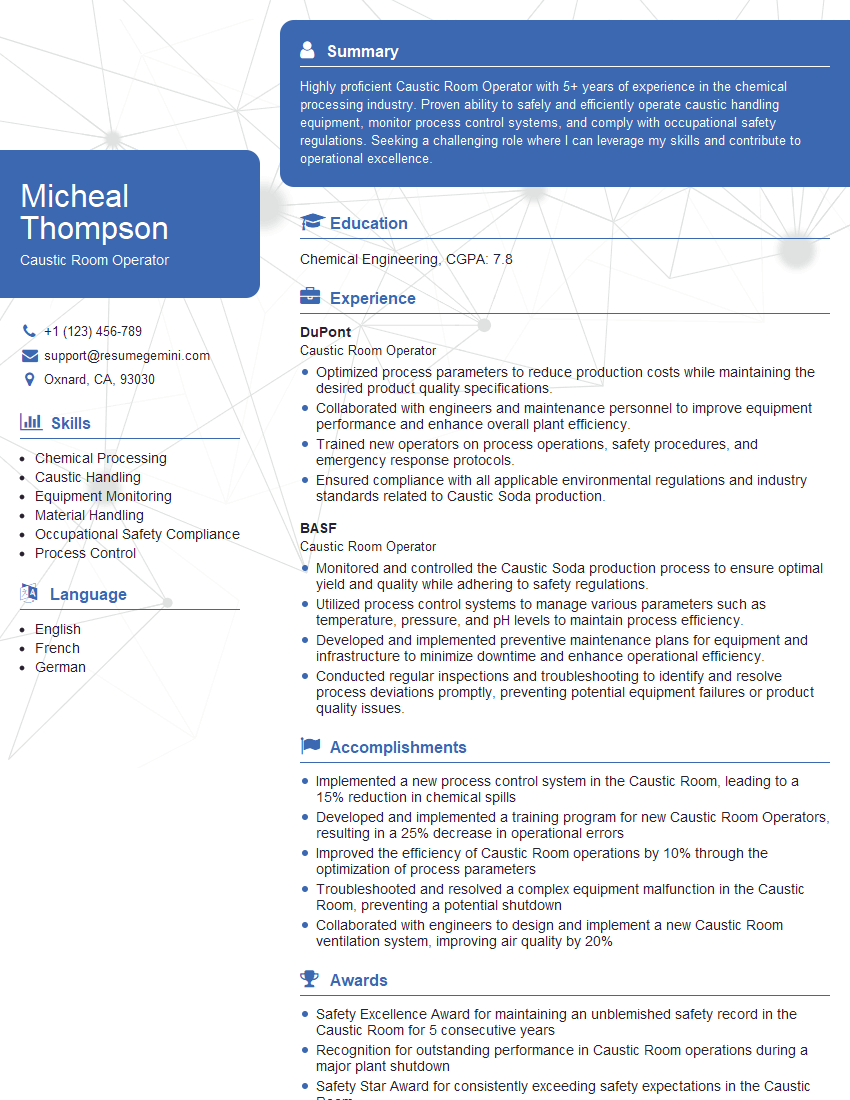

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Caustic Room Operator

1. Explain the process of caustic soda production using the Bayer process.

- Describe the steps involved in the Bayer process, including bauxite mining, digestion, clarification, precipitation, and calcination.

- Highlight the chemical reactions and principles underlying each step.

2. Describe the safety procedures and regulations associated with handling caustic soda.

Personal Protective Equipment

- Discuss the importance of wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators.

- Explain how to properly use and maintain PPE.

Emergency Response

- Outline the emergency protocols in case of caustic soda spills or exposure.

- Describe the first aid measures and medical treatments for caustic soda exposure.

3. Explain the role of caustic soda in wastewater treatment.

- Describe how caustic soda is used to adjust pH levels and remove impurities in wastewater.

- Discuss the advantages and disadvantages of using caustic soda in wastewater treatment.

4. Describe the methods used to control the concentration of caustic soda in a solution.

- Explain the use of titration and other analytical techniques to determine caustic soda concentration.

- Describe the principles behind maintaining a desired caustic soda concentration.

5. Explain the importance of maintaining equipment integrity in a caustic soda production facility.

- Describe the potential consequences of equipment failure, such as leaks, corrosion, and explosions.

- Discuss the steps involved in maintaining and inspecting equipment to prevent these failures.

6. Describe the process of troubleshooting common problems that may occur in a caustic soda production facility.

- Identify common problems, such as equipment malfunctions, process deviations, and quality control issues.

- Discuss the systematic approach to troubleshooting and resolving these problems.

7. Explain the importance of waste management and environmental compliance in a caustic soda production facility.

- Describe the waste streams generated in a caustic soda production facility.

- Discuss the regulations and best practices for managing these waste streams to minimize environmental impact.

8. Describe the principles of corrosion prevention in equipment used for caustic soda production.

- Explain the factors that contribute to corrosion in caustic soda environments.

- Discuss the materials and techniques used to prevent or minimize corrosion, such as corrosion-resistant alloys, coatings, and cathodic protection.

9. Describe the role of automation and process control in a caustic soda production facility.

- Explain the advantages of using automation and process control systems.

- Discuss the components and principles of these systems, such as sensors, controllers, and data acquisition systems.

10. Explain the importance of maintaining accurate records and documentation in a caustic soda production facility.

- Describe the types of records that should be maintained, such as production logs, maintenance records, and safety audits.

- Discuss the benefits of maintaining accurate records for quality control, regulatory compliance, and continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Caustic Room Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Caustic Room Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Caustic Room Operators are responsible for the safe and efficient operation of a caustic room in a chemical plant. They perform a variety of tasks, including:

1. Monitoring and controlling the caustic production process

Operators monitor the production process to ensure that the caustic is produced according to specifications. They make adjustments to the process as needed to maintain desired levels of alkalinity, temperature, and pH.

- Monitor process variables such as temperature, pressure, and flow rate.

- Adjust process parameters to maintain optimal operating conditions.

2. Performing routine maintenance on caustic room equipment

Operators perform routine maintenance on all equipment in the caustic room to ensure that it is in good working order. They inspect equipment for wear and tear, and replace or repair parts as needed.

- Lubricate and clean equipment to prevent wear and tear.

- Inspect equipment for signs of damage or malfunction.

3. Following safety procedures and protocols

Operators must follow all safety procedures and protocols when working in the caustic room. This includes wearing appropriate personal protective equipment (PPE), such as respirators, gloves, and goggles, and following safe work practices around caustic materials.

- Wear appropriate personal protective equipment (PPE) to prevent exposure to hazardous materials.

- Follow established safety protocols and procedures.

4. Troubleshooting and resolving production issues

Operators are responsible for troubleshooting and resolving any production issues that may occur. They analyze the situation and take corrective action to restore production to normal levels.

- Identify and troubleshoot production problems.

- Take corrective action to resolve issues and maintain production efficiency.

Interview Tips

To ace an interview for a Caustic Room Operator position, you can follow these preparation tips:

1. Research the company and the position

Take the time to learn about the company you’re interviewing with, their values, and their products or services. Also, familiarize yourself with the job description and make sure you understand the key responsibilities and qualifications.

- Visit the company’s website to learn about their history, mission, and products.

- Read the job description carefully to identify the key requirements and responsibilities.

2. Practice answering common interview questions

There are some common interview questions that you can expect to be asked in an interview for a Caustic Room Operator position. It’s a good idea to practice answering these questions in advance so that you can feel confident and prepared during your interview.

- Tell me about your experience with caustic materials.

- What are your strengths and weaknesses as a Caustic Room Operator?

- How do you handle working in a fast-paced, high-pressure environment?

3. Be prepared to talk about your safety experience

Safety is very important in a caustic room, so it’s important to be prepared to talk about your safety experience during your interview. Highlight any training or certifications you have in safety procedures, and be able to give examples of how you’ve followed safety protocols in the past.

- Describe your experience with following safety protocols and procedures.

- Provide examples of how you’ve identified and mitigated safety hazards.

4. Be prepared to answer technical questions

You may also be asked some technical questions during your interview, so it’s important to be prepared to answer these questions as well. Review your knowledge of the caustic production process, and be able to explain how you would troubleshoot and resolve common production issues.

- Explain the caustic production process and how you would monitor and control it.

- Describe how you would troubleshoot and resolve a common production issue.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Caustic Room Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.