Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cellophane Casting Machine Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

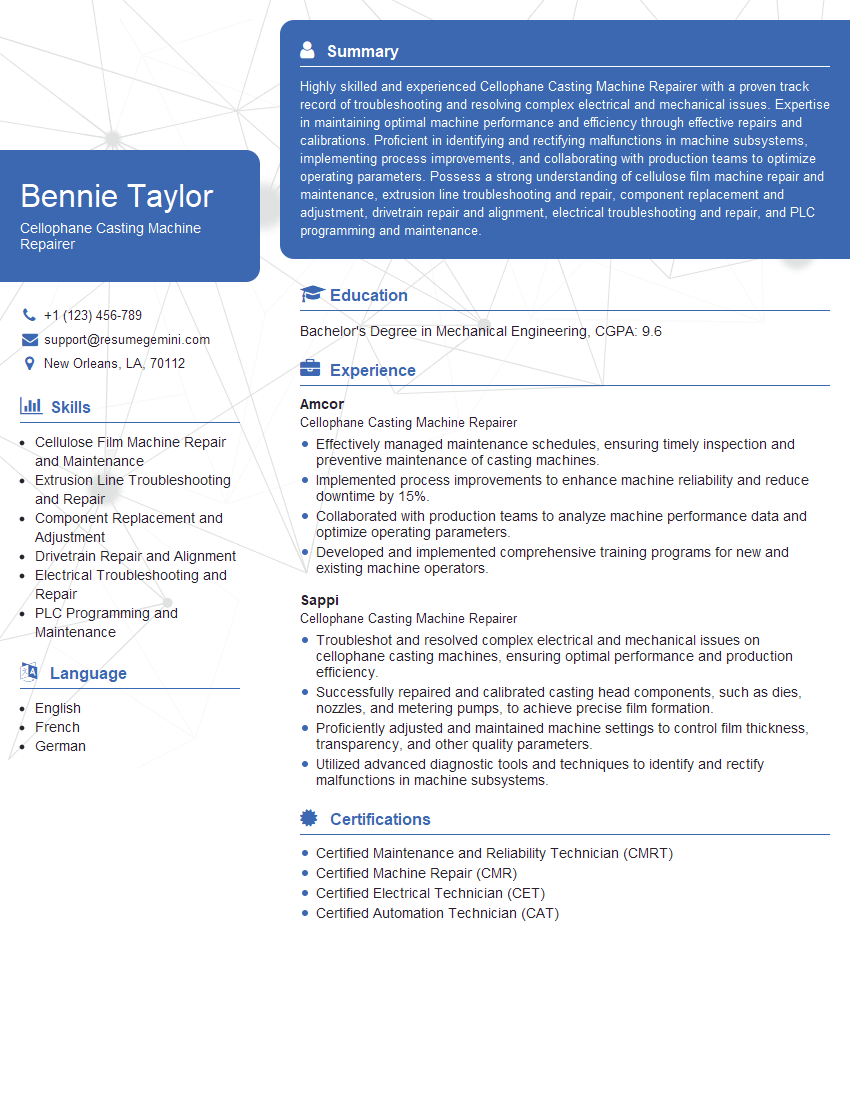

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cellophane Casting Machine Repairer

1. Explain the working principle of a cellophane casting machine?

The cellophane casting machine works on the principle of extruding a viscose solution through a die to form a thin film. The film is then coagulated in a chemical bath and dried to form cellophane.

- The viscose solution is prepared by dissolving cellulose in a caustic soda solution.

- The solution is then extruded through a die to form a thin film.

- The film is coagulated in a chemical bath to remove the caustic soda and form a cellulose film.

- The film is then dried to form cellophane.

2. What are the different types of cellophane casting machines?

Batch type

- The batch type machine produces cellophane in batches.

- The machine has a casting head and a drying chamber.

- The viscose solution is extruded through the casting head to form a film.

- The film is then coagulated in a chemical bath and dried in the drying chamber.

Continuous type

- The continuous type machine produces cellophane in a continuous process.

- The machine has a casting head, a coagulation bath, and a drying chamber.

- The viscose solution is extruded through the casting head to form a film.

- The film is then coagulated in the chemical bath and dried in the drying chamber.

3. What are the common problems that can occur with cellophane casting machines?

The common problems that can occur with cellophane casting machines include:

- Film breaks: Film breaks can be caused by a variety of factors, such as a damaged casting head, a worn die, or a contaminated viscose solution.

- Bubbles: Bubbles can be caused by air pockets in the viscose solution, a dirty casting head, or a contaminated chemical bath.

- Wrinkles: Wrinkles can be caused by a too-fast casting speed, a too-hot drying chamber, or a contaminated chemical bath.

- Spots: Spots can be caused by dirt or contaminants in the viscose solution, the chemical bath, or the drying chamber.

4. How do you troubleshoot a cellophane casting machine?

To troubleshoot a cellophane casting machine, you can follow these steps:

- Identify the problem: The first step is to identify the problem that is occurring with the machine.

- Check the machine: Once you have identified the problem, check the machine for any damage or wear.

- Clean the machine: If the machine is dirty, clean it thoroughly.

- Adjust the machine: If the machine is not operating properly, adjust the settings according to the manufacturer’s instructions.

- Replace parts: If the machine is damaged or worn, replace the parts according to the manufacturer’s instructions.

5. What are the safety precautions that should be taken when operating a cellophane casting machine?

The safety precautions that should be taken when operating a cellophane casting machine include:

- Wear protective clothing: Wear protective clothing, such as gloves, a lab coat, and safety glasses, when operating the machine.

- Be aware of the hazards: Be aware of the hazards associated with the machine, such as the moving parts, the hot surfaces, and the chemicals used.

- Follow the manufacturer’s instructions: Follow the manufacturer’s instructions for operating the machine.

- Do not operate the machine alone: Do not operate the machine alone.

- Keep the machine clean: Keep the machine clean to prevent accidents.

6. What are the maintenance procedures for a cellophane casting machine?

The maintenance procedures for a cellophane casting machine include:

- Daily maintenance: Daily maintenance includes cleaning the machine, checking for any damage or wear, and adjusting the settings.

- Weekly maintenance: Weekly maintenance includes lubricating the machine, checking the belts and chains, and cleaning the filters.

- Monthly maintenance: Monthly maintenance includes inspecting the machine for any major damage or wear, and replacing any parts that are worn or damaged.

- Annual maintenance: Annual maintenance includes a complete overhaul of the machine, including cleaning, inspecting, and replacing any parts that are worn or damaged.

7. What are the different types of film that can be produced on a cellophane casting machine?

The different types of film that can be produced on a cellophane casting machine include:

- Plain cellophane: Plain cellophane is a transparent film that is used for packaging food and other products.

- Coated cellophane: Coated cellophane is a film that has been coated with a material, such as wax or lacquer, to give it additional properties, such as moisture resistance or heat resistance.

- Metallized cellophane: Metallized cellophane is a film that has been coated with a thin layer of metal, such as aluminum, to give it a reflective surface.

- Holographic cellophane: Holographic cellophane is a film that has been embossed with a holographic pattern, which gives it a unique appearance.

8. What are the different applications of cellophane film?

The different applications of cellophane film include:

- Packaging: Cellophane film is used for packaging food, such as candy, bread, and cheese.

- Printing: Cellophane film is used for printing, such as labels and posters.

- Decorating: Cellophane film is used for decorating, such as gift wrapping and party decorations.

- Industrial: Cellophane film is used for industrial applications, such as electrical insulation and filtration.

9. What are the advantages of using cellophane film?

The advantages of using cellophane film include:

- Transparency: Cellophane film is transparent, which makes it ideal for packaging food and other products that need to be visible.

- Flexibility: Cellophane film is flexible, which makes it easy to wrap around products of different shapes and sizes.

- Moisture resistance: Cellophane film is moisture resistant, which helps to protect products from moisture and spoilage.

- Biodegradability: Cellophane film is biodegradable, which means that it can be broken down by microorganisms in the environment.

10. What are the disadvantages of using cellophane film?

The disadvantages of using cellophane film include:

- Cost: Cellophane film is more expensive than some other types of film, such as polyethylene film.

- Strength: Cellophane film is not as strong as some other types of film, such as polyester film.

- Heat resistance: Cellophane film is not as heat resistant as some other types of film, such as polypropylene film.

- Moisture absorption: Cellophane film can absorb moisture from the environment, which can make it less effective as a moisture barrier.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cellophane Casting Machine Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cellophane Casting Machine Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cellophane Casting Machine Repairers are responsible for maintaining, troubleshooting, and repairing cellophane casting machines. They must have a thorough understanding of the mechanics, hydraulics, and electrical systems of these machines, as well as the ability to identify and resolve problems quickly and efficiently.

1. Inspecting and maintaining machines

Inspecting machines regularly to identify potential problems and performing preventive maintenance tasks, such as cleaning and lubrication, to keep machines running smoothly.

2. Troubleshooting and repairing machines

Diagnosing problems with machines, performing repairs, and replacing or adjusting components as necessary to restore machines to working order.

3. Installing and setting up machines

Installing and setting up new machines or relocating existing machines, ensuring that machines are properly aligned and leveled and that all necessary safety precautions are in place.

4. Training operators

Training operators on how to use machines safely and efficiently and providing technical support to operators.

Interview Tips

Preparing for an interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview for a Cellophane Casting Machine Repairer position:

1. Research the company and the position

Before the interview, take some time to research the company and the specific position you are applying for. This will give you a better understanding of the company culture, the role’s responsibilities, and the qualifications they are looking for in a candidate.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions to ask the interviewer about the company, the position, or the team you would be working with.

4. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time and be prepared to make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cellophane Casting Machine Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!