Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cellophane Press Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

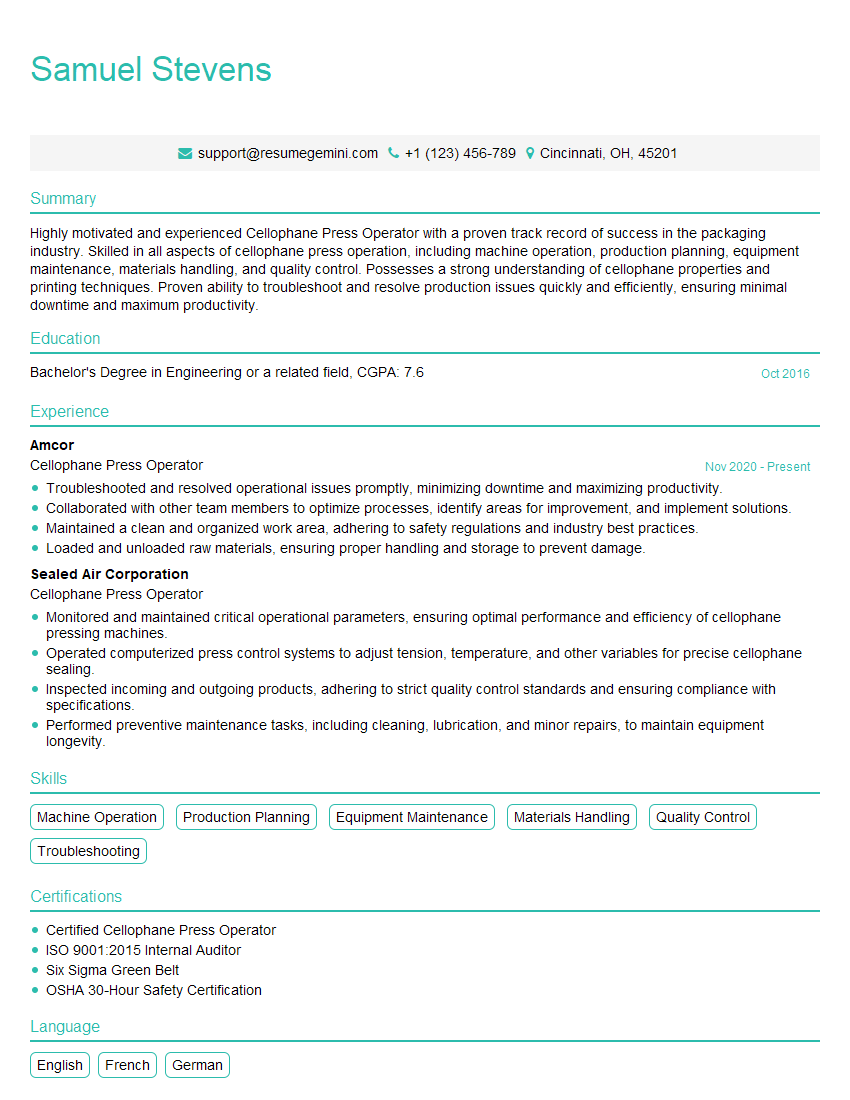

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cellophane Press Operator

1. Describe the process of setting up a cellophane press machine.

- Prepare the machine by ensuring that all necessary materials, such as cellophane rolls and adhesives, are in place.

- Adjust the machine’s settings to match the specifications of the product to be cellophane wrapped.

- Calibrate the machine to ensure accurate wrapping and sealing.

2. What are the common maintenance tasks required for a cellophane press machine?

Regular Maintenance

- Cleaning and lubricating moving parts to prevent friction and ensure smooth operation.

- Inspecting and replacing worn or damaged parts, such as belts and rollers.

- Checking and adjusting tension settings to maintain proper wrapping quality.

Periodic Maintenance

- Overhauling the machine’s major components, such as the drive system and heating elements.

- Conducting electrical and mechanical safety inspections.

- Performing software updates and calibrations.

3. How do you troubleshoot and resolve common problems encountered while operating a cellophane press machine?

- Identify the root cause of the problem by observing the machine’s performance and error messages.

- Consult the machine’s manual or technical documentation for specific troubleshooting procedures.

- Perform necessary adjustments or repairs, such as replacing faulty sensors or tightening loose connections.

- Calibrate the machine and test its operation to ensure the problem is resolved.

4. What quality control measures are essential for ensuring the quality of cellophane-wrapped products?

- Inspecting cellophane rolls for defects and ensuring their proper storage conditions.

- Monitoring the wrapping process to ensure consistent and accurate sealing.

- Performing regular product sampling and testing to verify product integrity and meet quality standards.

- Maintaining accurate records of quality control checks and implementing corrective actions as needed.

5. What safety precautions should be observed when operating a cellophane press machine?

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensuring that the machine is properly grounded and electrically safe.

- Keeping the work area clean and free of obstructions.

- Following established safety procedures for machine operation, maintenance, and cleaning.

6. What is your understanding of the different types of cellophane films used in packaging?

- Regenerated cellulose film: Made from plant-based materials, biodegradable, and moisture-proof.

- Moisture-proof cellophane: Coated with a moisture-resistant layer, ideal for packaging perishable products.

- Heat-sealable cellophane: Treated to allow heat-sealing, providing secure packaging.

- Metallized cellophane: Coated with a thin layer of metal, offering barrier protection and enhanced aesthetics.

7. How do you adjust the cellophane press machine’s settings to accommodate different product sizes and wrapping requirements?

- Adjust the machine’s conveyor speed to match the product’s size and flow.

- Modify the temperature and pressure settings to ensure proper sealing and film adhesion.

- Calibrate the machine’s sensors to accurately detect product dimensions and wrapping position.

8. What are the key maintenance tips to prolong the lifespan of a cellophane press machine?

- Regularly clean the machine’s components, especially the sealing bars and rollers.

- Lubricate moving parts to reduce friction and wear.

- Replace worn or damaged parts promptly to prevent further issues.

- Conduct periodic inspections and calibrations to maintain optimal performance.

9. How do you ensure the safe and efficient operation of a cellophane press machine in a production environment?

- Follow established safety protocols, such as wearing PPE and adhering to lockout/tagout procedures.

- Monitor the machine’s performance regularly and address any issues promptly.

- Train operators thoroughly on proper machine operation and maintenance.

- Implement a regular cleaning and maintenance schedule to prevent breakdowns.

10. What are some innovative applications of cellophane press technology in the packaging industry?

- Developing environmentally friendly packaging solutions using biodegradable cellophane films.

- Using advanced sensors and automation to improve machine efficiency and product quality.

- Exploring the use of cellophane films in flexible packaging and resealable applications.

- Integrating cellophane press technology with other packaging processes, such as printing and labeling.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cellophane Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cellophane Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cellophane Press Operators are responsible for the smooth and efficient operation of cellophane press machines. They ensure that the machines are properly set up and maintained, and that the cellophane is processed correctly. The main responsibilities of a Cellophane Press Operator are:

1. Machine Setup and Maintenance

Set up and adjust cellophane press machines according to specifications. Conduct regular maintenance and inspections to ensure that the machines are in good working order. Troubleshoot and repair minor machine malfunctions.

2. Cellophane Processing

Load cellophane rolls onto the machine. Monitor the cellophane as it passes through the press to ensure that it is being processed correctly. Adjust machine settings as needed to achieve the desired results.

3. Quality Control

Inspect the finished cellophane to ensure that it meets quality standards. Identify and correct any defects. Maintain records of all quality control checks.

4. Safety

Follow all safety procedures and regulations. Wear appropriate safety gear. Keep the work area clean and free of hazards.

Interview Tips

Preparing for an interview for a Cellophane Press Operator position can be daunting, but with the right strategies, you can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job.

2. Practice Common Interview Questions

There are some common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Highlight Your Skills and Experience

When answering interview questions, be sure to highlight your skills and experience that are relevant to the job. For example, if you have experience in operating cellophane press machines, be sure to mention this in your answer to the question “What are your strengths?”

4. Be Enthusiastic and Professional

First impressions matter, so be sure to arrive at the interview on time and dressed appropriately. Be enthusiastic and positive throughout the interview, and show the interviewer that you are genuinely interested in the position.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer any questions that you have about the position or the company. This shows that you are engaged and interested in the opportunity.

By following these tips, you can increase your chances of acing your interview for a Cellophane Press Operator position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cellophane Press Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cellophane Press Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.