Are you gearing up for an interview for a Cellophane Tester position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Cellophane Tester and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

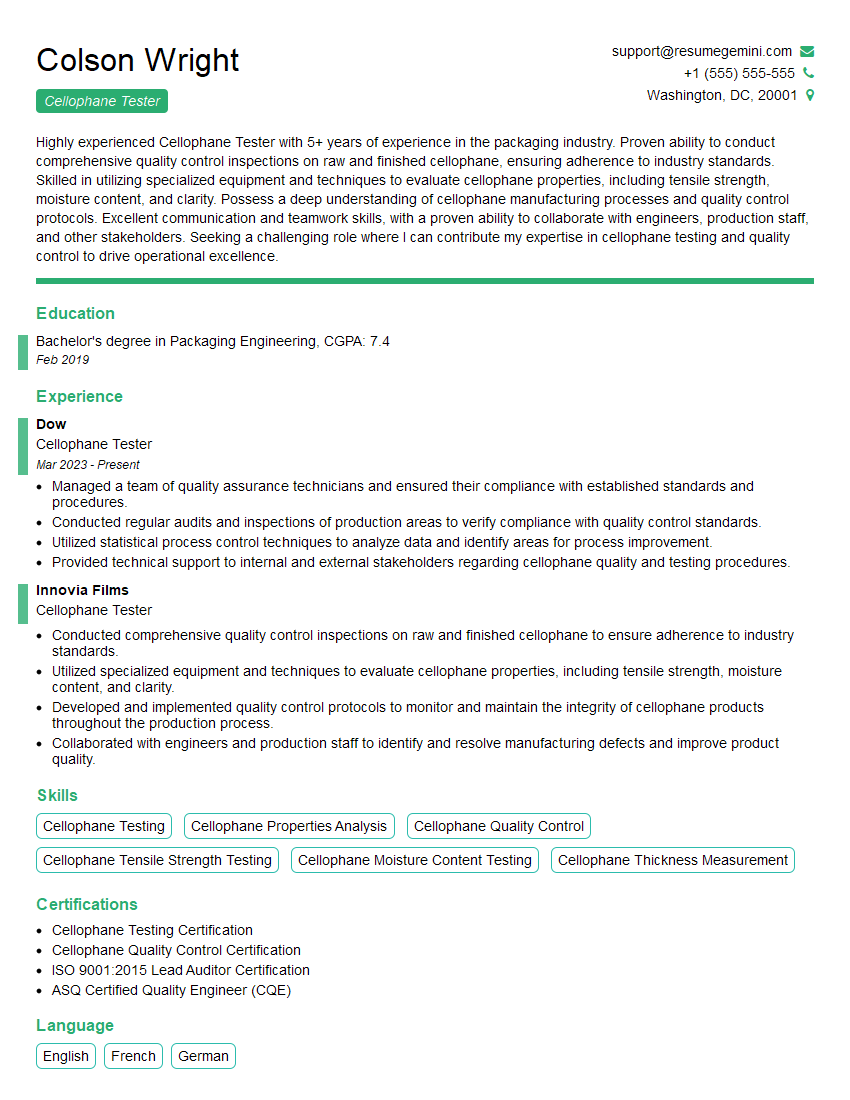

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cellophane Tester

1. What types of tests do you perform on cellophane to assess its quality?

In my role as a Cellophane Tester, I conduct a range of tests to evaluate the quality of cellophane, including:

- Opacity and Transparency: I measure the ability of cellophane to block light, ensuring that it meets the desired opacity or transparency level.

- Flatness and Smoothness: I assess the smoothness and flatness of cellophane, ensuring that it is free from wrinkles or surface irregularities.

- Moisture Resistance: I test the cellophane’s resistance to moisture absorption, which is crucial for protecting packaged goods from humidity and moisture damage.

- Tensile Strength: I determine the strength and elasticity of cellophane by measuring its resistance to tearing and stretching, ensuring that it can withstand handling and storage.

- Heat Sealability: I evaluate the cellophane’s ability to form strong heat seals, which is essential for packaging applications and ensuring product integrity.

2. Describe the equipment and techniques you use for cellophane testing.

Equipment:

- Opacimeter for opacity measurement

- Glossmeter for smoothness and flatness assessment

- Moisture analyzer for moisture resistance testing

- Tensile tester for tensile strength measurement

- Heat sealer for heat sealability evaluation

Techniques:

- ISO standards for opacity, moisture resistance, and tensile strength testing

- ASTM standards for heat sealability and smoothness assessment

- Statistical analysis to interpret results and ensure accuracy

3. How do you interpret test results and communicate them to stakeholders?

I interpret test results by comparing them to established standards and specifications. I analyze the data to identify any deviations from the desired quality parameters. I then communicate my findings clearly and concisely to stakeholders, including production, quality control, and management teams.

- Written reports with detailed analysis and recommendations for improvement

- Presentations to discuss test results and address any concerns

- Regular meetings to provide updates and seek feedback

4. What quality control measures do you implement to ensure the accuracy and consistency of your testing?

I adhere to strict quality control measures to ensure the accuracy and consistency of my testing:

- Calibration and Maintenance: I regularly calibrate and maintain all testing equipment to ensure precision and reliability.

- Standard Operating Procedures (SOPs): I follow established SOPs for each test procedure, ensuring consistency and minimizing errors.

- Blind Testing: I conduct blind testing to eliminate bias and ensure objectivity in result interpretation.

- Data Verification: I verify test data through multiple measurements and statistical analysis to reduce the likelihood of errors.

- Quality Audits: I participate in internal and external quality audits to assess the effectiveness of our quality control system.

5. How do you stay up-to-date with the latest industry standards and testing methodologies for cellophane?

- Attend industry conferences and workshops

- Read technical journals and publications

- Participate in online forums and discussion groups

- Collaborate with other professionals in the field

- Receive ongoing training from equipment manufacturers and regulatory agencies

6. Describe a complex testing problem you encountered and how you resolved it.

In one instance, I encountered an issue where cellophane samples were failing our tensile strength test despite meeting all other quality parameters. After thorough investigation, I discovered that the cellophane had been improperly stored, leading to moisture absorption and a reduction in tensile strength. I recommended adjusting the storage conditions and implementing a moisture control plan, which successfully resolved the issue.

7. How do you prioritize your workload and manage multiple testing projects simultaneously?

I prioritize my workload based on project urgency, deadlines, and resource availability. I use a task management system to track project progress and allocate resources effectively. I also prioritize tests that are critical to the release of new products or packaging materials. To manage multiple projects simultaneously, I break them down into smaller tasks and delegate responsibilities to other team members when feasible.

8. What is your understanding of the environmental impact of cellophane?

Cellophane is a biodegradable material, which means it can be broken down naturally by microorganisms. However, its production can have environmental implications, such as the use of wood pulp and the generation of wastewater. I am aware of the environmental concerns associated with cellophane and stay informed about ongoing efforts to reduce its impact. I believe that it is important to strike a balance between using sustainable packaging materials and ensuring product quality and safety.

9. How do you ensure that your testing results are reliable and accurate?

I employ several measures to ensure the reliability and accuracy of my testing results:

- Calibration: I regularly calibrate all testing equipment according to manufacturer specifications.

- Use of Reference Materials: I use certified reference materials to verify the accuracy of my testing methods.

- Blind Testing: I conduct blind testing to eliminate bias and ensure objectivity in result interpretation.

- Statistical Analysis: I use statistical analysis to identify trends, outliers, and potential errors in my data.

- Regular Audits: I participate in internal and external audits to assess the effectiveness of our quality control system.

10. What sets you apart from other candidates for this role?

- Extensive experience in cellophane testing and quality control

- In-depth knowledge of industry standards and testing methodologies

- Strong analytical and problem-solving skills

- Excellent communication and interpersonal skills

- Commitment to continuous improvement and professional development

I am confident that I have the technical expertise, experience, and personal qualities to excel in this role and contribute to the success of your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cellophane Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cellophane Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Cellophane Tester, you will be responsible for conducting a variety of tests to ensure the quality of cellophane products, including:

1. Conduct physical tests

Measuring thickness, tensile strength, elongation, and other physical properties of cellophane samples.

2. Perform chemical tests

Determining moisture content, wax content, and other chemical properties of cellophane samples.

3. Conduct optical tests

Evaluating transparency, gloss, and other optical properties of cellophane samples.

4. Monitor production processes

Observing and recording production parameters to ensure that cellophane products are meeting specifications.

Interview Tips

To ace your interview for a Cellophane Tester position, consider these tips:

1. Research the company and the position

This will help you understand the company’s culture, values, and the specific requirements of the role.

2. Practice your answers to common interview questions

Such as “Tell me about your experience in the field” and “Why are you interested in this position?”

3. Be prepared to discuss your technical skills and knowledge

Highlight your expertise in testing and evaluating cellophane products, and your knowledge of industry standards.

4. Be prepared to present your portfolio

If you have a portfolio of your work, be prepared to share it with the interviewer to demonstrate your skills.

5. Dress professionally and arrive on time for your interview

Make a good first impression and show that you are serious about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cellophane Tester interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.