Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cement Gun Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

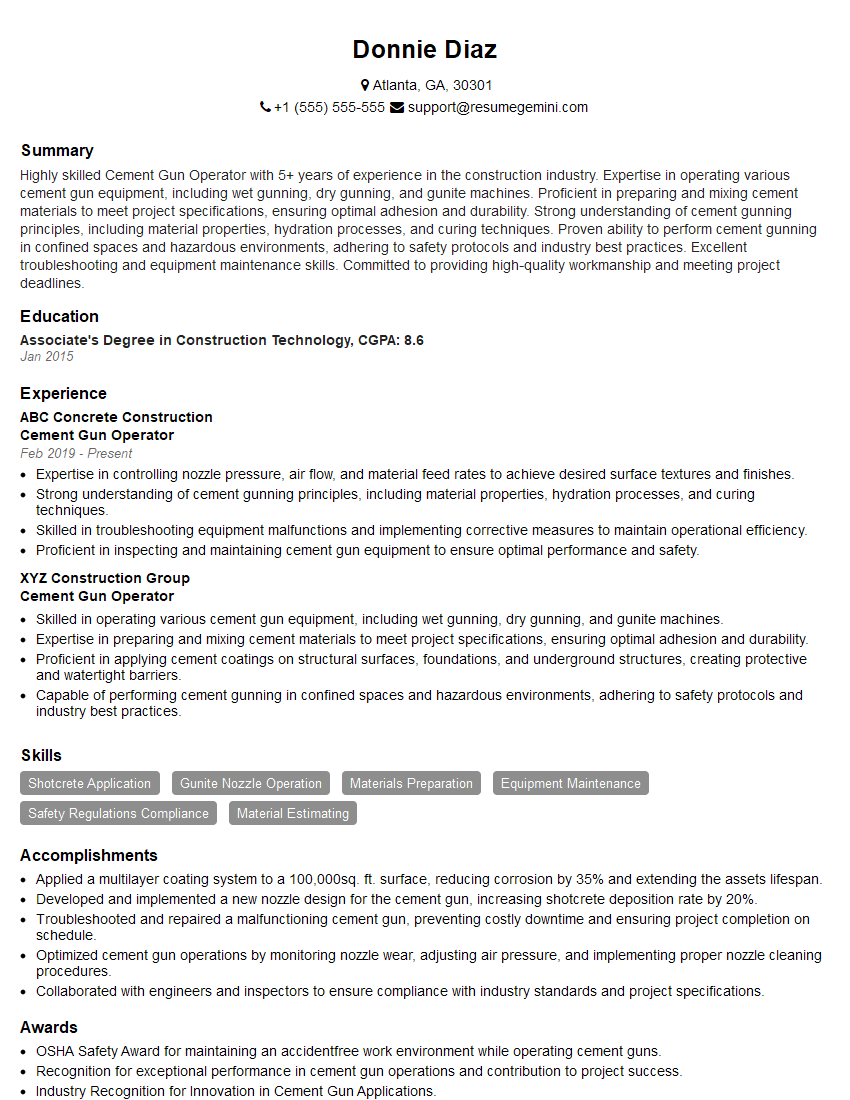

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Gun Operator

1. Describe the process of operating a cement gun?

Sample Answer – Gather necessary materials and equipment – Wear appropriate safety gear and clothing – Inspect equipment for any damages or malfunctions – Set up the cement gun and connect it to the compressor – Load the cement mix into the hopper – Adjust the nozzle settings for the desired spray pattern – Test the spray pattern and adjust as necessary – Begin applying the cement mix to the surface – Monitor the thickness and consistency of the applied cement – Smooth and finish the surface as needed

2. What are the safety precautions to be followed when operating a cement gun?

Sample Answer – Wear Personal Protective Equipment (PPE): Resprirator, gloves, eye protection, hearing protection – Ensure proper ventilation: Control dust and fumes to prevent respiratory issues – Inspect equipment: Check for any damage or malfunctions before use – Use safe operating techniques: Avoid over-spraying or sudden movements – Maintain a clean work area: Remove debris to prevent tripping hazards – Handle cement mix safely: Avoid skin contact and inhalation – Follow manufacturer’s instructions: Adhere to recommended safety guidelines for specific equipment

3. How do you troubleshoot common problems with a cement gun?

Sample Answer – Clogged Nozzle: Stop spraying, clear the nozzle using a wire or compressed air – Insufficient Pressure: Check the air supply and ensure the compressor is generating enough pressure – Watery Mix: Adjust the water-to-cement ratio to achieve a proper consistency – Uneven Spray: Clean the nozzle tip, adjust the air pressure, or replace the nozzle – Leaking Gun: Inspect hoses and connections for cracks or loose fittings, tighten or replace as needed – Overspraying: Adjust the nozzle settings or increase the distance from the surface – Rough Finish: Use a trowel or float to smooth the applied cement

4. Explain the different types of cement mixes used in cement guns and their applications?

Sample Answer – Portland Cement: General purpose, suitable for most applications – High-Early Strength Cement: Rapid curing, used for quick repairs – Expansive Cement: Expands during setting, reducing shrinkage and cracking – Polymer-Modified Cement: Enhanced strength, flexibility, and durability – Fiber-Reinforced Cement: Improved crack resistance and tensile strength – Refractory Cement: High heat resistance, used in furnaces and fireplaces – White Cement: Decorative purposes, provides a brighter finish

5. How do you maintain and clean a cement gun after use?

Sample Answer – Clean the Gun: Remove cement residue from the hopper, hoses, and nozzle using water or a solvent – Lubricate Moving Parts: Apply a light lubricant to the moving parts to prevent wear and tear – Inspect and Replace Filters: Check and replace air and water filters to ensure proper operation – Store Properly: Store the cement gun in a dry and protected area when not in use

6. Describe the techniques for applying cement using a cement gun?

Sample Answer – Dry-Mix Method: Using a dry cement mix and adding water at the nozzle – Wet-Mix Method: Preparing a cement slurry and pumping it through the gun – Gunning Technique: Holding the gun perpendicular to the surface and moving it smoothly to apply an even layer – Finishing Techniques: Using trowels, floats, or brushes to shape and smooth the applied cement

7. What are the factors that can affect the quality of the cement application?

Sample Answer – Proper Mix Design: Ensuring the correct proportions of cement, water, and additives – Equipment Condition: Using well-maintained equipment to avoid malfunctions – Operator Technique: Skilled operator with proper gunning techniques – Surface Preparation: Preparing the surface for optimal bonding – Environmental Conditions: Temperature, humidity, and wind speed can impact drying and curing

8. How do you measure the thickness of the applied cement layer?

Sample Answer – Wet Film Thickness Gauge: Measures the thickness of the wet cement layer before it dries – Dry Film Thickness Gauge: Measures the thickness of the dried cement layer – Ultrasonic Thickness Gauge: Measures the thickness through non-destructive means using sound waves – Micrometer: Measures the thickness of small areas or irregular surfaces

9. Explain the role of curing in the cement application process?

Sample Answer – Moist Curing: Keeping the applied cement moist to prevent cracking and promote hydration – Water Curing: Spraying water on the applied cement or covering it with damp materials – Membrane Curing: Applying a liquid membrane to retain moisture in the cement – Curing Compounds: Using chemical compounds to reduce moisture loss

10. How do you work effectively as part of a crew in a cement gun operation?

Sample Answer – Communication: Clearly communicate with team members to coordinate tasks and avoid delays – Proper Planning: Plan the work sequence and assign roles effectively – Teamwork: Collaborate with others to handle equipment, mix materials, and apply cement – Safety Awareness: Prioritize safety and follow established procedures to protect oneself and others – Problem-Solving: Work together to identify and resolve any challenges that arise during the operation

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Gun Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Gun Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cement Gun Operators are responsible for the operation, maintenance, and repair of cement guns, which are used to apply cement to surfaces in construction projects and mining operations.

1. Operate Cement Guns

Operate cement guns to apply cement to surfaces, using a variety of techniques, such as spraying, pumping, and grouting.

- Adjust the cement gun to ensure proper operation and application of cement.

- Monitor the cement gun during operation to ensure proper functioning and make adjustments as necessary.

2. Prepare and Maintain Equipment

Prepare and maintain cement guns, including cleaning, lubricating, and repairing equipment.

- Clean and lubricate cement guns and related equipment to ensure proper operation.

- Inspect cement guns and related equipment for wear and tear, and make repairs as necessary.

3. Supervise and Train Others

Supervise and train other workers in the use of cement guns and related equipment.

- Provide training to new employees on the proper use and maintenance of cement guns.

- Supervise and monitor the work of other employees to ensure that cement guns are used safely and effectively.

4. Ensure Safety and Compliance

Ensure that all safety regulations are followed when operating cement guns.

- Follow all safety regulations and procedures when operating cement guns.

- Ensure that all employees are properly trained and equipped to operate cement guns safely.

Interview Tips

To ace an interview for a Cement Gun Operator position, it is important to prepare thoroughly and demonstrate your knowledge and skills. Here are some tips to help you prepare for the interview:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the job.

- Visit the company’s website to learn about their mission, values, and recent projects.

- Read industry news and publications to stay up-to-date on the latest trends and technologies in the cement industry.

2. Practice Your Answers to Common Interview Questions

There are several common questions that you are likely to be asked in an interview for a Cement Gun Operator position. Practicing your answers to these questions will help you feel more confident and prepared during the interview.

- Tell me about your experience operating cement guns.

- What are your strengths and weaknesses as a Cement Gun Operator?

- How do you ensure safety when operating cement guns?

3. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. This includes your technical skills, such as your ability to operate and maintain cement guns, as well as your soft skills, such as your ability to work independently and as part of a team.

- Quantify your accomplishments whenever possible. For example, instead of saying “I operated cement guns,” say “I operated cement guns to apply over 100,000 square feet of concrete on a major construction project.”

- Use specific examples to demonstrate your skills and experience. For example, instead of saying “I am a team player,” say “I worked on a team of cement gun operators to complete a large-scale grouting project on time and within budget.”

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

- Dress in business casual attire, such as a button-down shirt and slacks or a skirt.

- Arrive for your interview at least 10 minutes early. This will give you time to relax and collect your thoughts before the interview begins.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cement Gun Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!