Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cement Mason position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

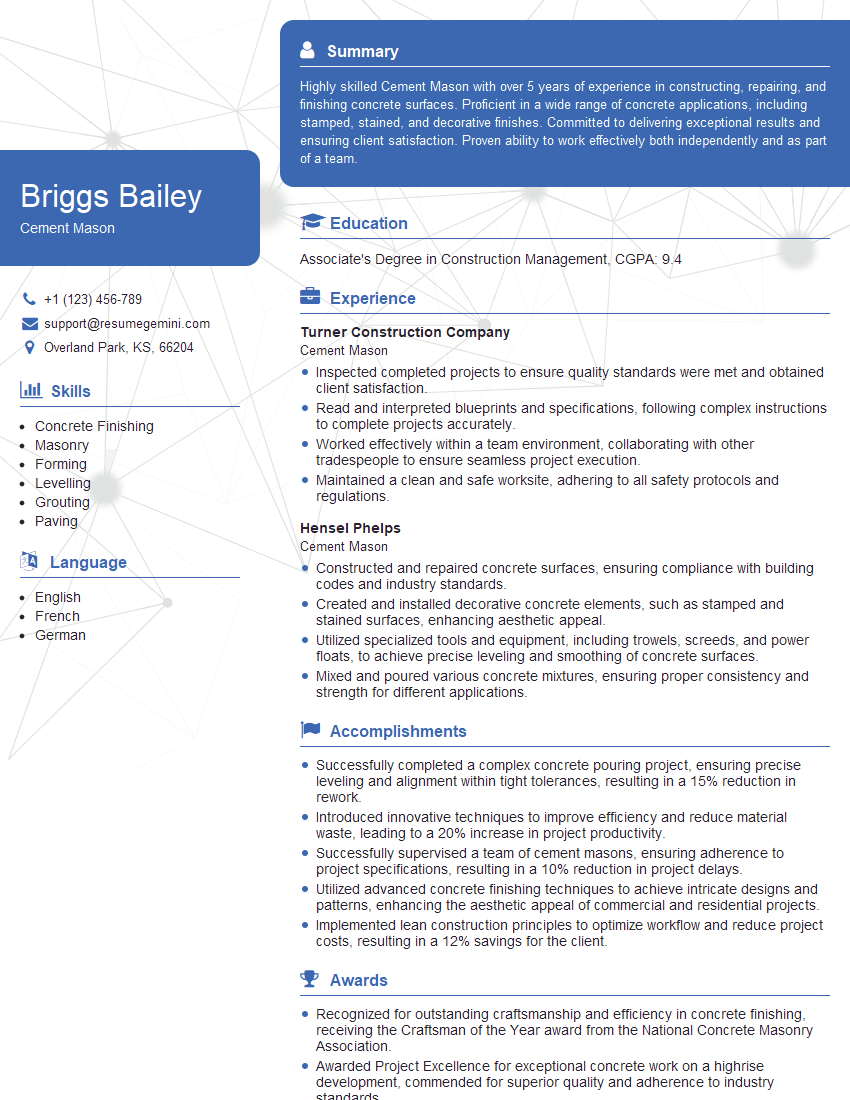

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Mason

1. How do you ensure the flatness and level of the concrete surface?

To ensure the flatness and level of the concrete surface, I use a variety of tools and techniques, including:

- Screeds to level the concrete and remove any high spots.

- Bull floats to smooth the surface and remove any trowel marks.

- Edgers to create clean, straight edges around the concrete.

- Levels to check the flatness and level of the surface.

2. Can you describe the process of installing a concrete slab?

Preparing the Site

- Excavate the area where the slab will be installed.

- Compact the soil and install a gravel base.

- Form the edges of the slab using wood or metal.

Pouring the Concrete

- Order the concrete and have it delivered to the site.

- Pour the concrete into the form and level it using a screed.

- Trowel the surface of the concrete to smooth it.

Finishing the Concrete

- Allow the concrete to cure for several days.

- Cut control joints into the concrete to prevent cracking.

- Seal the concrete to protect it from the elements.

3. What are the different types of concrete finishes and how do you achieve them?

There are many different types of concrete finishes that can be achieved, depending on the desired look and texture. Some of the most common finishes include:

- Smooth finish: This finish is achieved by troweling the surface of the concrete until it is smooth and even.

- Broom finish: This finish is achieved by brushing the surface of the concrete with a broom while it is still wet. This creates a rough, textured surface.

- Exposed aggregate finish: This finish is achieved by removing the top layer of concrete to expose the aggregate beneath. This creates a rough, textured surface with a unique look.

- Stamped concrete finish: This finish is achieved by stamping a pattern into the wet concrete. This can create a variety of different looks, such as brick, stone, or tile.

4. How do you repair cracks in concrete?

To repair cracks in concrete, I follow these steps:

- Clean the crack: Remove any dirt or debris from the crack using a wire brush or air compressor.

- Widen the crack: Use a grinder or chisel to widen the crack slightly. This will help the repair material to better penetrate the crack.

- Apply a bonding agent: Apply a bonding agent to the crack to help the repair material adhere to the concrete.

- Fill the crack: Fill the crack with a concrete repair material. Use a trowel to smooth the repair material and level it with the surrounding concrete.

- Cure the repair: Allow the repair material to cure according to the manufacturer’s instructions.

5. What are the safety precautions that you take when working with concrete?

When working with concrete, I take a number of safety precautions to protect myself and others from injury. These precautions include:

- Wearing appropriate clothing: I wear long pants, a long-sleeved shirt, gloves, and safety glasses when working with concrete.

- Using proper tools: I use sharp tools and keep them in good condition. I also use the right tools for the job.

- Working in a well-ventilated area: I work in a well-ventilated area to avoid inhaling concrete dust.

- Protecting myself from falls: I use ladders and scaffolds safely and avoid working at heights.

- Being aware of my surroundings: I am aware of my surroundings and take precautions to avoid tripping or falling.

6. What are the different types of concrete admixtures and how do they affect the properties of concrete?

There are many different types of concrete admixtures that can be used to improve the properties of concrete. Some of the most common types of admixtures include:

- Water reducers: These admixtures help to reduce the amount of water needed to make concrete, which can improve the strength and durability of the concrete.

- Accelerators: These admixtures help to accelerate the setting time of concrete, which can be useful in cold weather or when it is necessary to speed up the construction process.

- Retarders: These admixtures help to retard the setting time of concrete, which can be useful in hot weather or when it is necessary to delay the finishing process.

- Air-entraining agents: These admixtures help to introduce air into concrete, which can improve the freeze-thaw resistance of the concrete.

7. How do you test the strength of concrete?

There are a number of different ways to test the strength of concrete. Some of the most common methods include:

- Compressive strength test: This test measures the amount of force required to crush a concrete cylinder.

- Flexural strength test: This test measures the amount of force required to break a concrete beam.

- Tensile strength test: This test measures the amount of force required to pull a concrete specimen apart.

8. What are the different types of reinforcement that can be used in concrete?

There are many different types of reinforcement that can be used in concrete to improve its strength and durability. Some of the most common types of reinforcement include:

- Steel reinforcing bars: These are the most common type of reinforcement used in concrete. They are made of steel and are available in a variety of sizes and shapes.

- Welded wire fabric: This type of reinforcement is made of welded steel wires. It is available in sheets or rolls and is used to reinforce concrete slabs and walls.

- Fiber reinforcement: This type of reinforcement is made of small fibers that are added to the concrete mix. It helps to improve the strength and toughness of concrete.

9. How do you calculate the amount of concrete needed for a project?

To calculate the amount of concrete needed for a project, I use the following formula:

Volume of concrete = Length x Width x Depth

Once I have calculated the volume of concrete needed, I add 10% to the total to account for waste and spillage.

10. How do you control the quality of concrete?

To control the quality of concrete, I follow a number of steps, including:

- Using high-quality materials: I use high-quality cement, aggregates, and water to make concrete.

- Testing the concrete: I test the concrete to ensure that it meets the specified strength and durability requirements.

- Properly placing and curing the concrete: I properly place and cure the concrete to ensure that it reaches its full strength and durability potential.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Mason.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Mason‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cement Masons are responsible for laying and finishing concrete surfaces, both indoors and outdoors.

1. Laying Concrete

This involves preparing the area where the concrete will be laid, ensuring that it is level and free of debris. Once the area is prepared, the cement mason will mix the concrete and pour it into place.

- Prepare the area where the concrete will be laid, ensuring that it is level and free of debris.

- Mix the concrete according to the manufacturer’s instructions.

- Pour the concrete into place and level it using a screed.

2. Finishing Concrete

Once the concrete has been laid, the cement mason will finish it to the desired level of smoothness and texture. This may involve using a trowel, a float, or a broom.

- Use a trowel to smooth the surface of the concrete.

- Use a float to level the surface of the concrete.

- Use a broom to create a textured surface on the concrete.

3. Repairing Concrete

Cement masons are also responsible for repairing damaged concrete surfaces. This may involve patching holes, cracks, or other defects.

- Patch holes in the concrete surface.

- Repair cracks in the concrete surface.

- Repair other defects in the concrete surface.

4. Safety

In addition to these responsibilities, cement masons must also comply with all safety regulations applicable to their work. This may involve wearing protective clothing and equipment, following proper lifting procedures, and working in a safe environment.

- Wear protective clothing and equipment, such as gloves, safety glasses, and a hard hat.

- Follow proper lifting procedures to avoid injury.

- Work in a safe environment, free from hazards such as tripping hazards and electrical hazards.

Interview Tips

Preparing for an interview for a Cement Mason position can be daunting, but with the right approach, you can increase your chances of success.

1. Research the Company and the Position

Take the time to learn about the company you are applying to and the specific position you are interviewing for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take the time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be Prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as a Cement Mason. Be prepared to discuss your previous projects, your expertise in concrete laying and finishing, and your ability to work independently and as part of a team.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and make eye contact with the interviewer. Answer the interviewer’s questions honestly and thoughtfully, and be sure to ask questions of your own at the end of the interview.

Additional Tips

- Bring a portfolio of your work to the interview if you have one.

- Be prepared to take a skills test, such as a concrete laying or finishing test.

- Follow up with the interviewer after the interview to thank them for their time and to reiterate your interest in the position.

Next Step:

Now that you’re armed with the knowledge of Cement Mason interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cement Mason positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini