Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cement Mixer Driver interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cement Mixer Driver so you can tailor your answers to impress potential employers.

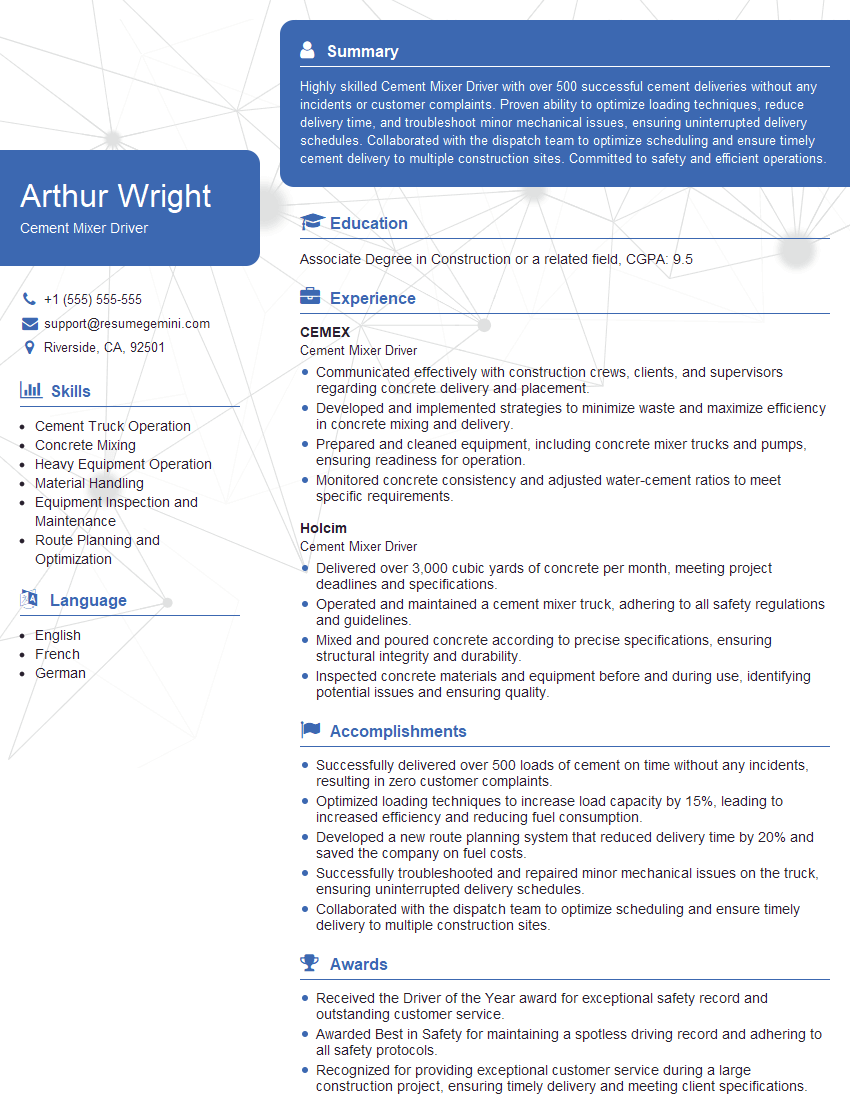

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Mixer Driver

1. How do you ensure that the cement mixer is clean and in good working condition before each use?

– Conduct thorough visual inspections of the mixer, checking for any damage or wear. – Inspect the blades, drum, and other components for proper alignment and functionality. – Test the discharge system to ensure smooth operation and prevent blockages. – Clean the mixer thoroughly using water or cleaning agents to remove any residual cement or debris.

2. What safety precautions do you take when operating a cement mixer?

Personal Protective Equipment:

- Wear appropriate safety gear, including gloves, eye protection, and a dust mask.

- Ensure clothing is not loose or flowing, which could get caught in the machinery.

Machine Operation:

- Inspect the mixer daily for any defects or hazards before operating.

- Securely fasten the drum and prevent unauthorized access to the mixing area.

- Operate the mixer within safe load limits and avoid overloading.

3. How do you determine the correct amount of water to add to the cement mix?

– Follow the manufacturer’s instructions and consult with site engineers or project supervisors. – Perform slump tests to determine the consistency of the mix and adjust water content accordingly. – Consider environmental factors, such as temperature and humidity, which can affect the water requirements. – Use measuring tools, such as graduated buckets or flow meters, to ensure accurate water measurement.

4. What are the signs of a properly mixed cement batch?

– Uniform consistency throughout the mix, with no segregation or lumps. – Adequate workability, allowing for easy placement and finishing. – Meets the specified slump or consistency requirements for the application. – Appropriate set time, allowing for proper placement and curing.

5. How do you troubleshoot common problems that may arise during cement mixing?

- Clogged discharge chute: Clear obstructions and ensure proper lubrication.

- Leaking drum: Tighten bolts or replace gaskets to prevent leakage.

- Overheating engine: Check oil levels, coolants, and fan operation.

- Excessive vibration: Inspect bearings, belts, and couplings for wear or damage.

- Pneumatic system failure: Inspect hoses, fittings, and compressors for leaks or malfunctions.

6. How do you handle the disposal of excess or unused cement mix?

– Dispose of excess mix responsibly according to local regulations. – Allow the mix to cure and harden, then dispose of it as concrete waste. – Do not pour liquid cement mix down drains or onto the ground to prevent environmental contamination.

7. What maintenance tasks do you perform on a cement mixer to ensure its longevity?

- Regularly clean and lubricate moving parts to minimize wear.

- Inspect and replace worn or damaged components promptly.

- Conduct periodic oil changes and filter replacements.

- Check tire pressure and tread wear for optimal performance.

- Follow manufacturer’s maintenance recommendations and consult with experts when needed.

8. How do you handle emergencies or accidents involving the cement mixer?

- Assess the situation and ensure safety of personnel.

- Contact emergency responders immediately, if necessary.

- Secure the mixer and prevent further damage or spills.

- Cooperate with authorities and provide accurate information.

- Follow established emergency protocols and procedures.

9. How do you measure the weight or volume of cement mix loaded onto the truck?

– Use a calibrated weight scale or load indicator to determine the exact weight of the mix. – Calculate the volume based on the mix design proportions and the truck’s drum capacity. – Ensure accurate measurements to comply with project specifications and prevent overloading.

10. What factors influence the selection of different types of cement mixers for various construction projects?

- Project size and scale: Larger projects require mixers with higher capacities.

- Type of cement mix: Different mixes may require specialized mixing equipment.

- Site conditions: Compact spaces or remote locations may require smaller or portable mixers.

- Environmental regulations: Some mixers may comply with stricter environmental standards than others.

- Budgetary constraints: Cost considerations can influence the choice of mixer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Mixer Driver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Mixer Driver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cement Mixer Drivers are entrusted with the critical task of transporting and delivering cement to construction sites. They operate specialized vehicles equipped with rotating drums to mix cement with water and other materials, ensuring a consistent and smooth concrete mix.

1. Cement Mixing and Delivery

The primary responsibility of a Cement Mixer Driver is to operate the cement mixer truck safely and efficiently. This involves:

- Loading the truck with dry cement and water according to specified proportions.

- Operating the mixing drum to blend the ingredients thoroughly, creating a homogeneous concrete mix.

- Delivering the mixed concrete to construction sites, ensuring it is discharged accurately and on time.

2. Truck Maintenance and Inspection

To ensure the smooth operation and safety of the cement mixer truck, drivers are responsible for:

- Performing daily inspections of the vehicle, including checking fluids, tires, and brake systems.

- Maintaining the truck’s cleanliness, including washing the mixing drum and other components.

- Reporting any mechanical issues or concerns to the supervisor or maintenance team promptly.

3. Safety Compliance and Regulations

Cement Mixer Drivers play a crucial role in adhering to safety regulations and protocols:

- Following all safety procedures and wearing appropriate protective gear during operation.

- Ensuring that the vehicle is in good working condition and meets safety standards.

- Complying with regulations governing the transportation and handling of hazardous materials.

4. Customer Service and Communication

Effective communication and customer service skills are essential for Cement Mixer Drivers:

- Interacting with customers, answering their queries, and providing information about concrete delivery.

- Maintaining a professional and courteous demeanor, even in challenging situations.

- Coordinating with construction crews and site managers to ensure smooth delivery and placement of concrete.

Interview Tips

To ace the interview for a Cement Mixer Driver position, candidates should focus on the following key tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge of the company and the construction industry. Research their projects, safety record, and any recent news or developments.

2. Highlight Your Experience and Skills

Emphasize your experience in operating cement mixer trucks, including the types of vehicles you have driven and the size of projects you have worked on. Showcase your ability to mix and deliver concrete according to specifications.

3. Focus on Safety and Compliance

Highlight your commitment to safety and compliance. Explain your understanding of safety regulations and how you ensure the safe operation of your vehicle. Discuss your experience in handling hazardous materials and adhering to industry standards.

4. Prepare for Common Questions

Anticipate and prepare for common interview questions related to your experience, skills, and safety practices. Practice answering questions confidently and concisely, showcasing your knowledge and abilities.

5. Be Enthusiastic and Punctual

Show enthusiasm for the role and the industry. Arrive on time for your interview and dress professionally. A positive attitude and a genuine interest in the job will make a lasting impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cement Mixer Driver interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!