Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cement Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

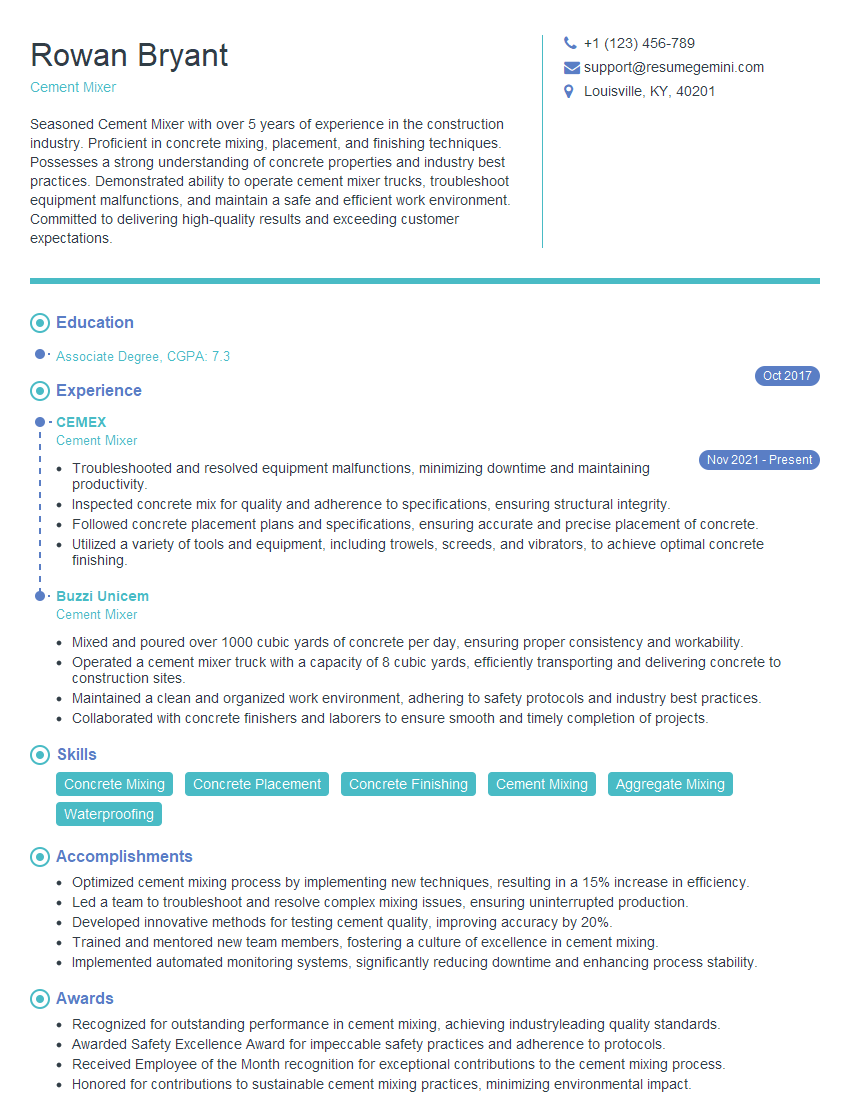

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Mixer

1. What are the different types of cement mixers?

- Truck mounted

- Tractor mounted

- Self-loading

- Portable

2. What are the key components of a cement mixer?

Drum

- Holds the concrete mixture

- Rotates to mix the concrete

Blades

- Attached to the inside of the drum

- Mix the concrete

Water tank

- Holds water

- Added to the concrete mixture

Cement hopper

- Holds cement

- Added to the concrete mixture

Engine

- Powers the mixer

- Different types of engines available

3. How does a cement mixer work?

- The cement, water, and aggregate are loaded into the drum.

- The drum rotates, and the blades mix the ingredients together.

- The concrete is mixed until it reaches the desired consistency.

- The concrete is then discharged from the drum.

4. What are the safety precautions that should be taken when operating a cement mixer?

- Wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Inspect the cement mixer before each use to ensure that it is in good working condition.

- Never operate a cement mixer under the influence of drugs or alcohol.

- Be aware of your surroundings and stay clear of moving parts.

5. How do you troubleshoot a cement mixer that is not mixing properly?

- Check the blades to make sure that they are not worn or damaged.

- Check the water tank to make sure that there is enough water.

- Check the cement hopper to make sure that there is enough cement.

- Check the engine to make sure that it is running properly.

6. What are the different types of concrete that can be made with a cement mixer?

- Regular concrete

- Lightweight concrete

- High-strength concrete

- Self-compacting concrete

7. What are the advantages of using a cement mixer to make concrete?

- Produces a more consistent mix than mixing by hand.

- Saves time and labor.

- Can be used to make large quantities of concrete.

- Portable models are available for use on-site.

8. What are the disadvantages of using a cement mixer to make concrete?

- More expensive than mixing by hand.

- Requires more maintenance than mixing by hand.

- Can be difficult to clean.

- Can be dangerous to operate if not used properly.

9. What are the different types of attachments that can be used with a cement mixer?

- Hopper extensions

- Drum covers

- Concrete pumps

- Water tanks

10. What are the future trends in cement mixer technology?

- Increased use of automation

- Development of more efficient and environmentally friendly models

- Increased use of portable models

- Development of new types of attachments

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cement Mixer is primarily responsible for operating and maintaining cement mixers to produce concrete or cementitious mixtures used in construction projects.

1. Equipment Operation

- Operate cement mixers, ensuring proper mixing of cement, sand, water, and other materials.

- Monitor mixer levels and adjust as needed to maintain desired consistency and quality.

- Control the discharge of concrete or cementitious mixtures into trucks or other containers.

2. Quality Control

- Adhere to established quality standards and specifications for cement mixtures.

- Perform tests and inspections to ensure that the mixture meets project requirements.

- Adjust mixing parameters as needed to optimize concrete performance.

3. Equipment Maintenance

- Perform routine maintenance tasks such as greasing, cleaning, and minor repairs.

- Report any major equipment issues or malfunctions promptly to supervisors.

- Assist with major repairs or overhauls as required.

4. Safety and Compliance

- Follow all safety protocols and regulations related to cement mixing operations.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

To ace an interview for the role of a Cement Mixer, candidates should prepare thoroughly and demonstrate their skills, experience, and knowledge of the industry.

1. Research the Company and Position

- Research the company’s background, industry standing, and the specific role you are applying for.

- Understand the company’s values, mission, and goals to align your skills and experience accordingly.

2. Highlight Relevant Skills and Experience

- Emphasize your hands-on experience in operating and maintaining cement mixers.

- Showcase your knowledge of cement mixing techniques and quality control procedures.

- Provide specific examples of projects where you have successfully mixed and delivered concrete mixtures.

3. Demonstrate Safety and Compliance Awareness

- Highlight your understanding of safety protocols and regulations related to cement mixing operations.

- Explain your commitment to maintaining a safe work environment and following PPE guidelines.

4. Prepare for Common Interview Questions

- Practice answering common interview questions related to cement mixing, equipment operation, and quality control.

- Prepare examples of challenging situations you have faced and how you resolved them.

5. Be Professional and Punctual

- Dress professionally and arrive for your interview on time.

- Maintain a positive and enthusiastic attitude throughout the interview.

- Be respectful of the interviewer’s time and ask relevant questions to show your interest.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cement Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!