Are you gearing up for a career in Cementing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cementing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

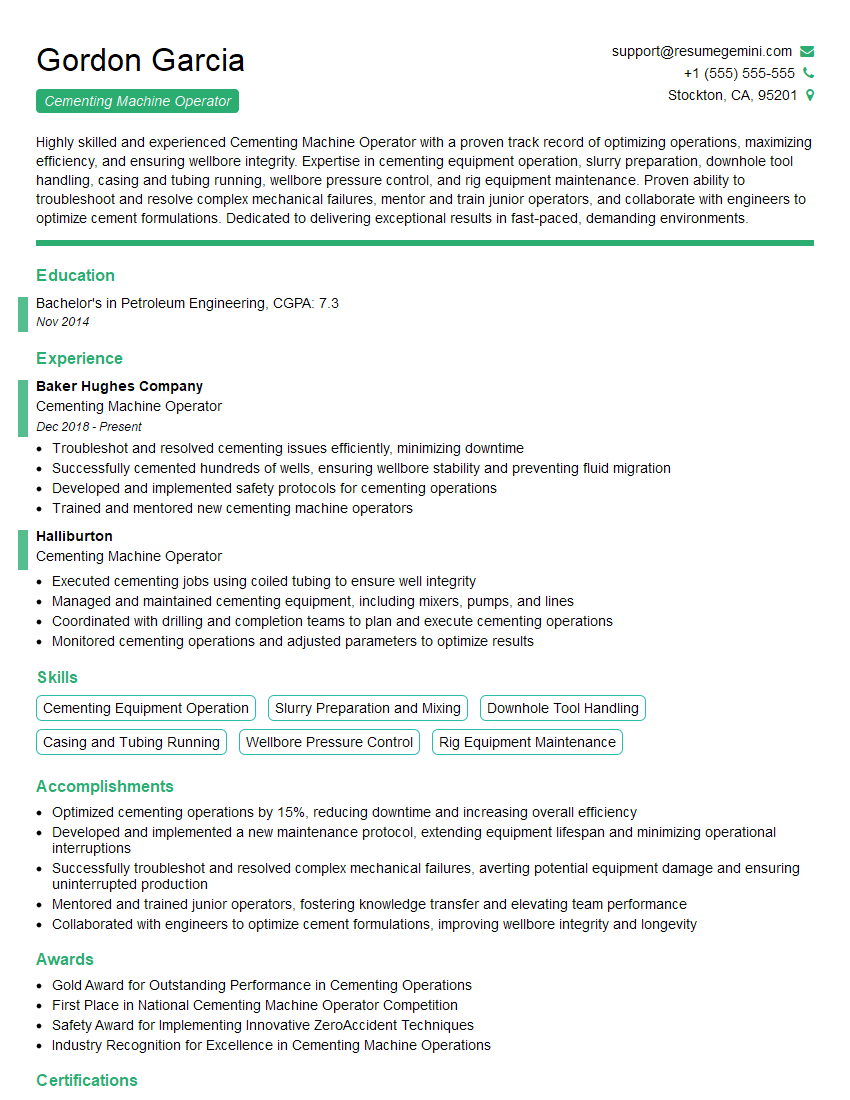

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cementing Machine Operator

1. Can you explain the basic principles of cementing and the role of a Cementing Machine Operator?

Sample Answer:

- Cementing involves pumping cement slurry down the wellbore to seal and stabilize the casing and prevent fluid migration.

- As a Cementing Machine Operator, I am responsible for operating and maintaining the cementing unit, ensuring proper mixing and pumping of the cement slurry.

2. What are the different types of cements used in oil and gas wells, and their specific applications?

Types of Cement

- Ordinary Portland Cement (OPC): General-purpose cement

- Pozzolan Cement: Enhanced durability and resistance to chemical attack

- Neat Cement: Pure cement, high strength and low permeability

Applications

- OPC: Shallow wells, temporary operations

- Pozzolan Cement: Corrosive environments, deeper wells

- Neat Cement: Critical zones, gas-tight sealing

3. Describe the process of mixing and pumping cement slurry.

Sample Answer:

- Weigh and measure cement and additives according to specifications.

- Mix cement with water and additives in the mixing hopper.

- Control pump pressure and flow rate to ensure proper slurry density and placement.

- Monitor slurry properties and make adjustments as needed.

4. What are the safety precautions and regulations that apply to Cementing Machine Operators?

- Wear appropriate PPE (hard hat, gloves, safety glasses)

- Follow established safety procedures

- Be aware of potential risks and hazards (electrical, mechanical, chemical)

- Comply with industry regulations and company policies

5. What are the different types of equipment used in cementing operations, and their functions?

Equipment

- Cementing Unit: Mixes and pumps slurry

- Pumps: High-pressure pumps for slurry injection

- Measuring Equipment: To ensure accurate slurry mixing

- Mixing Hopper: Container for mixing cement

- Float Collar: Device to set cement plug at desired depth

Functions

- Slurry preparation

- Pumping and placement

- Monitoring and control

- Wellbore sealing and isolation

6. What are the common challenges faced by Cementing Machine Operators, and how do you overcome them?

Challenges

- Varying well conditions and slurry properties

- Equipment breakdowns and malfunctions

- Time constraints and deadlines

- Safety hazards and environmental concerns

Solutions

- Thorough planning and preparation

- Flexibility and adaptability to changing circumstances

- Effective communication and teamwork

- Adherence to safety protocols

7. What is the role of cement additives, and how do you select the appropriate ones for different applications?

- Additives can modify slurry properties (e.g., density, viscosity, setting time)

- Proper selection ensures optimal cementing performance

- Factors to consider: well conditions, temperature, pressure, cement type

8. How do you ensure the quality of cement during and after placement?

- Proper mixing and pumping procedures

- Monitoring slurry properties (density, viscosity, etc.)

- Conducting pressure tests to assess cement integrity

- Taking core samples for analysis

9. What are the environmental considerations and regulations that apply to cementing operations?

- Minimizing waste generation

- Proper disposal of used cement and additives

- Air quality control

- Compliance with environmental laws and regulations

10. How do you maintain and troubleshoot the cementing unit and associated equipment?

- Regular inspections and preventive maintenance

- Troubleshooting common malfunctions (e.g., pump failures, pressure drops)

- Use of diagnostic tools and technical manuals

- Seeking assistance from experienced technicians when needed

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cementing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cementing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cementing Machine Operators are responsible for operating and maintaining cementing machines used in the construction industry. They ensure that the machines are functioning properly and that the cement is mixed and applied correctly. Key job responsibilities include:

1. Machine Operation

Operate cementing machines to mix, pump, and apply cement to construction surfaces.

- Set up and calibrate equipment

- Monitor machine performance and make adjustments as needed

2. Cement Handling

Handle cement safely and efficiently, including loading, unloading, and mixing.

- Measure and add ingredients to achieve desired cement consistency

- Ensure proper mixing and hydration of cement

3. Quality Control

Monitor the quality of cement and ensure that it meets specifications.

- Test cement samples for consistency, strength, and other properties

- Identify and correct any deviations from quality standards

4. Equipment Maintenance

Perform routine maintenance and repairs on cementing machines.

- Clean, lubricate, and inspect equipment

- Identify and replace worn or damaged parts

5. Safety Compliance

Adhere to all safety regulations and procedures when operating cementing machines.

- Wear appropriate safety gear

- Follow established work practices to minimize risks

Interview Preparation Tips

To ace an interview for a Cementing Machine Operator position, it is important to be well-prepared. Here are some interview preparation tips:

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific role you are applying for. This will help you understand the company’s culture, values, and expectations for the position. You can visit the company website, read industry news, and connect with current or former employees on LinkedIn.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. Some common questions for Cementing Machine Operator positions may include:

- “Tell me about your experience operating cementing machines.”

- “Describe your understanding of cement properties and quality control procedures.”

- “How do you ensure the safe and efficient operation of cementing equipment?”

3. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that make you a suitable candidate for the position. Quantify your accomplishments whenever possible, using specific examples of projects or tasks you have completed successfully.

4. Ask Thoughtful Questions

Preparing insightful questions to ask the interviewer demonstrates your interest in the role and the company. This also gives you the opportunity to clarify any aspects of the position or company culture that you may be curious about. Some questions you could consider include:

- “What are the current challenges and opportunities facing the cementing industry?”

- “How does the company prioritize safety and environmental sustainability in its operations?”

- “What are the company’s plans for future growth and innovation?”

5. Dress Professionally and Be Punctual

First impressions matter, so make sure you dress appropriately for the interview. Arrive on time to show respect for the interviewer’s schedule. Punctuality demonstrates your professionalism and time management skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cementing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!