Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Center Machine Set-Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

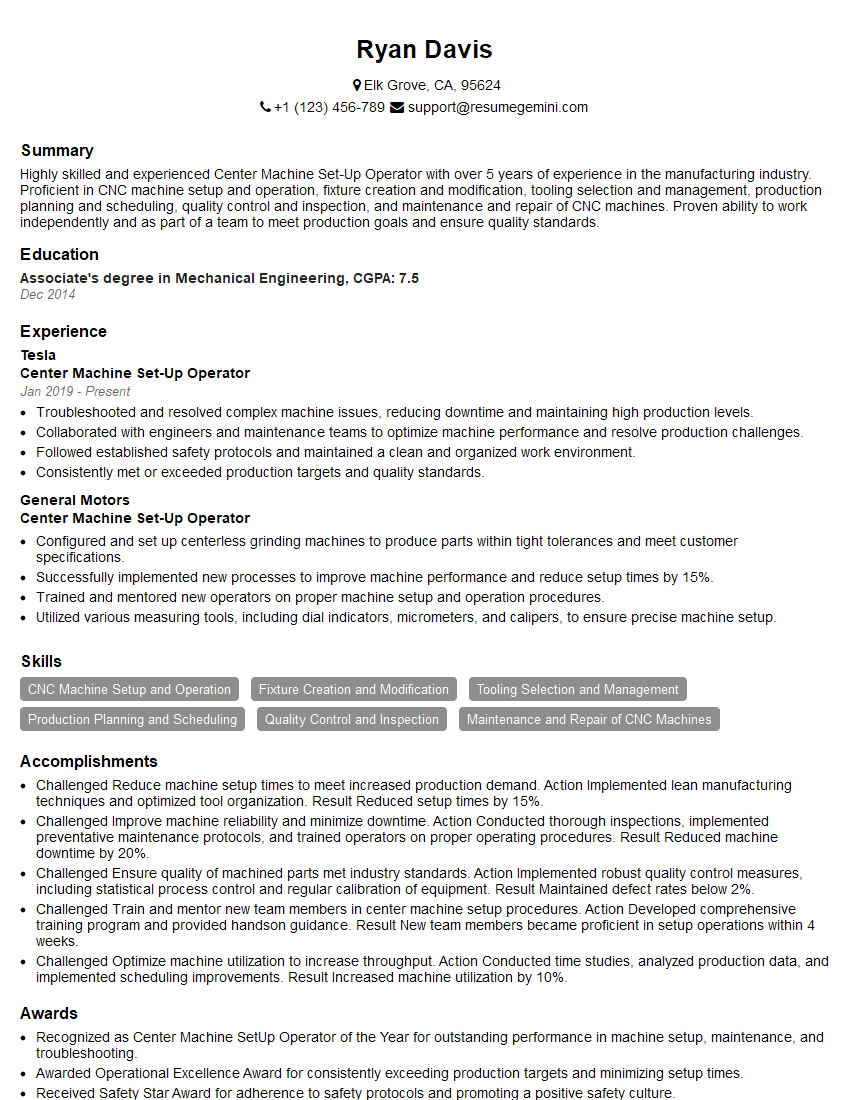

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Center Machine Set-Up Operator

1. Describe the key responsibilities of a Center Machine Set-Up Operator?

As a Center Machine Set-Up Operator, my responsibilities include:

- Setting up and adjusting CNC machining centers to ensure optimal production and efficiency

- Installing and aligning cutting tools, fixtures, and workpieces

- Programming and operating CNC machines to produce high-quality parts

- Performing preventive maintenance and troubleshooting to minimize downtime

- Inspecting finished parts to ensure they meet specifications and requirements

2. What types of CNC machines have you worked with?

Horizontal Machining Center

- Expertise in setting up and operating horizontal machining centers

- Experience in machining complex parts with tight tolerances

Vertical Machining Center

- Proficient in programming and operating vertical machining centers

- Skilled in producing high-volume parts with precision

3. Explain the process of setting up a CNC machine for a new job?

Setting up a CNC machine for a new job typically involves the following steps:

- Reviewing the job order and engineering drawings to understand the part specifications

- Selecting and installing the appropriate cutting tools and fixtures

- Creating or modifying the CNC program to generate the desired part geometry

- Setting up the machine parameters, such as feed rates, spindle speeds, and cutting depths

- Running a test cycle to verify the setup and program

4. How do you ensure that the parts produced by the CNC machine meet the required specifications?

To ensure that the parts produced by the CNC machine meet the required specifications, I follow these quality control measures:

- Inspecting raw materials before machining

- Using precision measuring tools to check part dimensions

- Performing regular machine calibration and maintenance

- Complying with established quality standards and procedures

5. What are the common problems that you have encountered while operating CNC machines?

Some common problems that I have encountered while operating CNC machines include:

- Tool breakage due to improper setup or excessive cutting forces

- Machine errors caused by mechanical or electrical failures

- Part defects resulting from incorrect programming or machining parameters

- Unexpected tool wear or workpiece damage due to improper cutting conditions

- Software glitches or communication issues between the machine and computer

6. How do you troubleshoot and resolve problems with CNC machines?

To troubleshoot and resolve problems with CNC machines, I follow these steps:

- Identifying the problem and its potential causes

- Checking machine settings, programs, and tools

- Performing diagnostic tests and error code analysis

- Consulting with maintenance personnel or technical support

- Implementing corrective actions, such as adjusting parameters, replacing tools, or repairing components

7. How do you stay updated with the latest CNC technologies and best practices?

To stay updated with the latest CNC technologies and best practices, I engage in the following activities:

- Attending industry workshops and conferences

- Reading technical articles and white papers

- Exploring online resources and forums

- Participating in training programs and certifications

- Seeking guidance from experienced colleagues and mentors

8. What are your strengths and weaknesses as a Center Machine Set-Up Operator?

Strengths:

- Strong technical skills in CNC programming and operation

- Attention to detail and accuracy

- Problem-solving and troubleshooting abilities

- Experience in working in a team environment

- Commitment to quality and continuous improvement

Weaknesses:

- Limited experience with certain specialized CNC machining techniques

- Working under pressure in fast-paced environments

9. Why are you interested in this position?

I am interested in this position because it aligns with my skills and experience as a Center Machine Set-Up Operator. I am eager to contribute to your team and leverage my expertise to support your manufacturing operations. I am confident that my abilities and dedication can make a valuable addition to your organization.

10. What are your salary expectations?

My salary expectations are based on my experience, skills, and the market value for similar positions in this industry. I am open to discussing a competitive salary package that is commensurate with my qualifications and the company’s compensation structure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Center Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Center Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Center Machine Set-Up Operators are responsible for setting up and operating centerless grinding machines. They ensure that the machines are properly calibrated and that the grinding wheels are correctly dressed. They also load and unload workpieces, monitor the grinding process, and make adjustments as needed. In addition, they may be responsible for maintaining and repairing the machines.

1. Setting up and operating centerless grinding machines

Center Machine Set-Up Operators are responsible for setting up and operating centerless grinding machines. They must be able to read and interpret blueprints and work orders, and they must have a good understanding of the grinding process. They must also be able to troubleshoot and repair minor problems with the machines.

- Read and interpret blueprints and work orders

- Set up and operate centerless grinding machines

- Troubleshoot and repair minor problems with the machines

2. Calibrating the machines and dressing the grinding wheels

Center Machine Set-Up Operators must be able to calibrate the machines and dress the grinding wheels. This requires a high level of precision and attention to detail. They must also be able to use a variety of tools and equipment.

- Calibrate the machines

- Dress the grinding wheels

- Use a variety of tools and equipment

3. Loading and unloading workpieces

Center Machine Set-Up Operators are responsible for loading and unloading workpieces. They must be able to handle heavy objects and they must be able to work quickly and efficiently.

- Load and unload workpieces

- Handle heavy objects

- Work quickly and efficiently

4. Monitoring the grinding process and making adjustments as needed

Center Machine Set-Up Operators must be able to monitor the grinding process and make adjustments as needed. They must be able to identify any problems with the process and they must be able to take corrective action.

- Monitor the grinding process

- Make adjustments as needed

- Identify any problems with the process

- Take corrective action

5. Maintaining and repairing the machines

Center Machine Set-Up Operators may be responsible for maintaining and repairing the machines. This requires a basic understanding of mechanics and electricity. They must also be able to use a variety of tools and equipment.

- Maintain and repair the machines

- Have a basic understanding of mechanics and electricity

- Use a variety of tools and equipment

Interview Tips

Preparing for a job interview can be stressful, but there are some things you can do to improve your chances of success. Here are a few tips:

1. Research the company and the position

Before you go to an interview, it’s important to do your research. Learn as much as you can about the company and the position you’re applying for. This will help you answer questions intelligently and show the interviewer that you’re genuinely interested in the job.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice your answers to common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It’s helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re respectful of their time and that you’re serious about the job.

- Choose appropriate clothing

- Be clean and well-groomed

- Arrive on time

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the job. The interviewer wants to get to know you and see if you’re a good fit for the company. Don’t try to be someone you’re not, and don’t be afraid to show your personality.

- Be confident and enthusiastic

- Be yourself

- Show the interviewer that you’re interested in the job

5. Follow up after the interview

After the interview, it’s important to follow up with the interviewer. This shows that you’re interested in the job and that you’re still a candidate. You can follow up by sending a thank-you note or by calling the interviewer to check on the status of your application.

- Send a thank-you note

- Call the interviewer to check on the status of your application

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Center Machine Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!