Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Centrifugal Casting Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Centrifugal Casting Machine Operator so you can tailor your answers to impress potential employers.

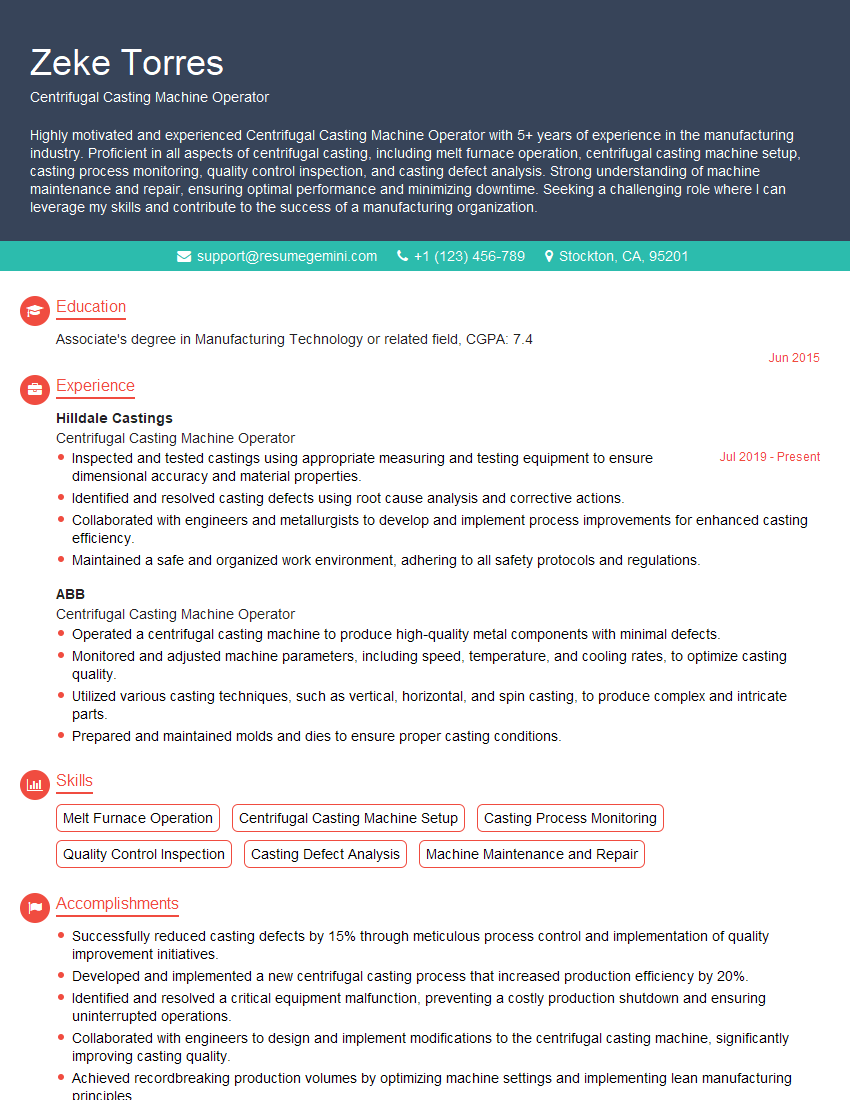

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Casting Machine Operator

1. What are the key responsibilities of a Centrifugal Casting Machine Operator?

- Operate and maintain centrifugal casting machines to produce castings.

- Set up and adjust machines, including molds, dies, and other components.

- Monitor the casting process and make adjustments as needed.

- Inspect castings for defects and ensure they meet specifications.

- Maintain a clean and safe work environment.

2. What are the different types of centrifugal casting machines? Describe their pros and cons.

Horizontal Centrifugal Casting Machine

- Pros: Produces castings with high accuracy and dimensional stability.

- Cons: Limited to producing castings with relatively small diameters.

Vertical Centrifugal Casting Machine

- Pros: Can produce castings with larger diameters than horizontal machines.

- Cons: Less accurate than horizontal machines.

3. What are the safety precautions that should be taken when operating a centrifugal casting machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Ensure that the machine is properly grounded and that all guards are in place.

- Never operate the machine when it is not properly maintained.

- Be aware of the potential for molten metal spills and take precautions to avoid injury.

- Follow all safety protocols and procedures.

4. What are the common defects that can occur in centrifugal casting? How can these defects be prevented or minimized?

- Porosity: Caused by air or gas trapped in the molten metal. Can be prevented by degassing the metal before casting.

- Shrinkage: Occurs when the metal solidifies and contracts. Can be minimized by using a mold with a slight taper.

- Cracking: Caused by stresses in the casting. Can be prevented by using a mold with a proper design and by cooling the casting slowly.

5. What are the different types of materials that can be cast using a centrifugal casting machine?

- Ferrous metals: Iron, steel, and stainless steel.

- Non-ferrous metals: Aluminum, copper, and bronze.

- Alloys: Such as brass and nickel-silver.

6. What are the advantages of using a centrifugal casting machine over other casting methods?

- Produces castings with high accuracy and dimensional stability.

- Can produce castings with complex shapes.

- Has a high production rate.

- Is relatively easy to operate.

7. What are the maintenance requirements for a centrifugal casting machine?

- Regularly clean and lubricate the machine.

- Inspect the machine for wear and tear.

- Calibrate the machine regularly.

- Follow the manufacturer’s recommended maintenance schedule.

8. What are the troubleshooting steps that should be taken if a centrifugal casting machine is not working properly?

- Check the power supply.

- Check the machine for any loose connections.

- Inspect the machine for any damaged components.

- Reset the machine.

- Contact the manufacturer for assistance.

9. What are the latest trends in centrifugal casting technology?

- The use of advanced materials.

- The development of new casting techniques.

- The use of automation.

- The use of computer-aided design (CAD) and computer-aided manufacturing (CAM).

10. How do you stay up to date with the latest developments in centrifugal casting technology?

- Attend industry conferences and trade shows.

- Read industry publications.

- Take online courses.

- Network with other professionals in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Casting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Casting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Centrifugal Casting Machine Operators are responsible for the operation and maintenance of centrifugal casting machines. They ensure that the machines are running smoothly and efficiently, and that the castings produced meet the required specifications.

1. Machine Operation

Operators are responsible for starting, stopping, and monitoring the centrifugal casting machine. They must also adjust the machine settings to ensure that the castings are produced to the correct specifications.

- Start, stop, and monitor the centrifugal casting machine.

- Adjust the machine settings to ensure that the castings are produced to the correct specifications.

2. Mold Preparation

Operators are responsible for preparing the molds for the centrifugal casting process. This includes cleaning the molds, applying a release agent, and assembling the molds.

- Clean the molds.

- Apply a release agent to the molds.

- Assemble the molds.

3. Casting Production

Operators are responsible for pouring the molten metal into the molds and centrifuging the molds to create the castings. They must also remove the castings from the molds and inspect them for defects.

- Pour the molten metal into the molds.

- Centrifuge the molds to create the castings.

- Remove the castings from the molds.

- Inspect the castings for defects.

4. Machine Maintenance

Operators are responsible for performing routine maintenance on the centrifugal casting machine. This includes cleaning the machine, lubricating the moving parts, and inspecting the machine for wear and tear.

- Clean the machine.

- Lubricate the moving parts.

- Inspect the machine for wear and tear.

Interview Tips

Preparing for an interview for a Centrifugal Casting Machine Operator position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work at the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. By practicing your answers to these questions, you can increase your confidence and deliver polished responses.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with centrifugal casting machines?

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of the interview shows that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the job.

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company’s culture like?

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Be on time for your interview.

- Make eye contact and shake hands with the interviewer.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Centrifugal Casting Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.