Are you gearing up for an interview for a Centrifugal Casting Machine Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Centrifugal Casting Machine Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

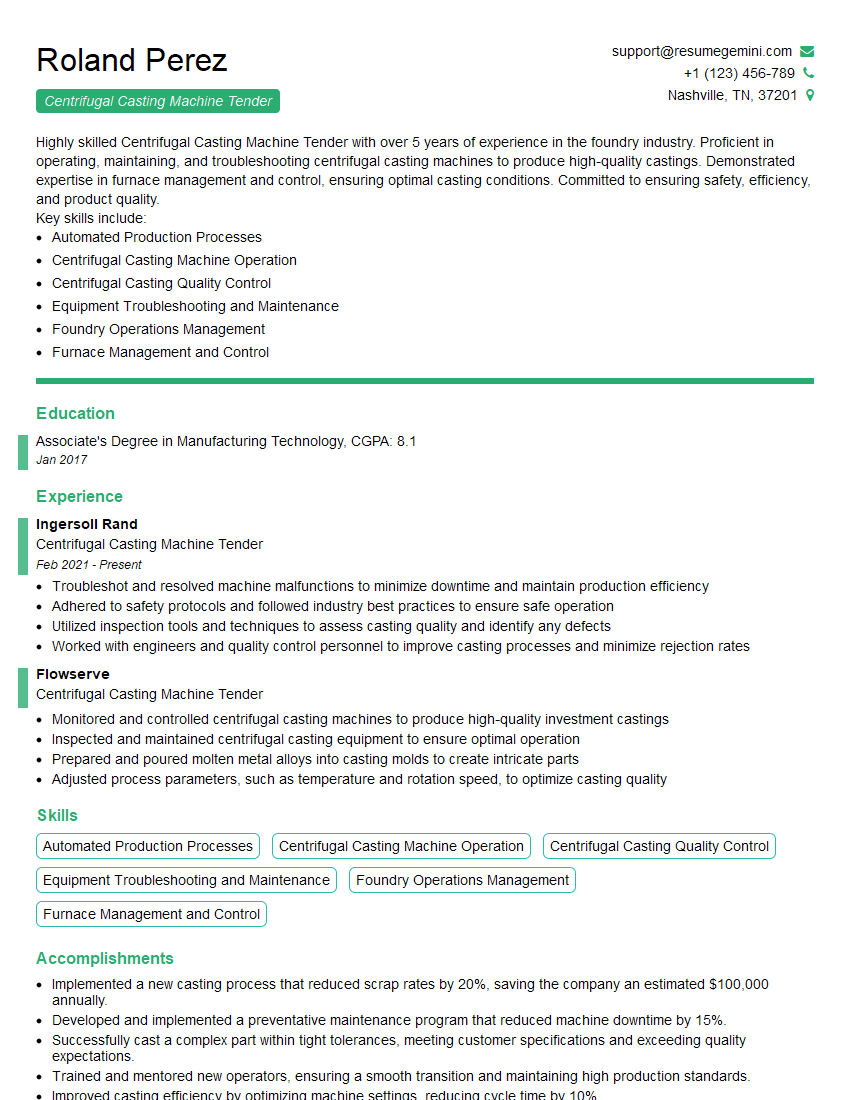

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Casting Machine Tender

1. What are the key responsibilities of a Centrifugal Casting Machine Tender?

- Setting up and operating centrifugal casting machines

- Ensuring the correct operation of the machine

- Monitoring and adjusting process parameters

- Inspecting castings for defects

- Maintaining and repairing the machine

2. Describe the process of centrifugal casting.

- The molten metal is poured into a rotating mold, which causes the metal to spread evenly along the mold walls.

- The centrifugal force helps to eliminate porosity and other defects in the casting.

Centrifugal casting is a metal casting process that uses centrifugal force to distribute molten metal into a mold.

Advantages of centrifugal casting:

- Produces castings with high strength and density

- Reduces porosity and other defects

- Improves surface finish

3. What are the different types of centrifugal casting machines?

- Horizontal centrifugal casting machines

- Vertical centrifugal casting machines

- Centrifugal casting machines with heated molds

- Centrifugal casting machines with vacuum

4. What are the safety precautions that must be taken when operating a centrifugal casting machine?

- Wear appropriate personal protective equipment (PPE)

- Ensure that the machine is properly grounded

- Do not operate the machine if it is damaged or malfunctioning

- Keep the work area clean and free of tripping hazards

- Be aware of the location of the emergency stop button

5. What is the role of metallurgy in centrifugal casting?

- Metallurgists can help to select the right alloy for a particular application.

- They can also help to develop heat treatment processes that will improve the strength and durability of the castings.

Metallurgy is the science of metals. It plays an important role in centrifugal casting because it helps to determine the properties of the castings.

6. What are the common defects in centrifugal castings?

- Porosity

- Shrinkage

- Cold shuts

- Cracks

- Inclusions

7. How can defects in centrifugal castings be prevented?

- Use the correct alloy

- Ensure that the mold is properly designed

- Control the pouring temperature

- Use the correct casting speed

- Inspect the castings carefully after they have been cast

8. What are the applications of centrifugal casting?

- Automotive parts

- Aerospace parts

- Medical devices

- Jewelry

- Art objects

9. What are the challenges of centrifugal casting?

- Producing castings with complex shapes

- Controlling the grain structure of the castings

- Preventing defects

- Meeting the demands of high-volume production

10. What are the future trends in centrifugal casting?

- The use of new alloys

- The development of new casting techniques

- The use of automation and robotics

- The integration of centrifugal casting with other manufacturing processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Casting Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Casting Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Centrifugal Casting Machine Tender is responsible for the operation and maintenance of centrifugal casting machines used in the production of metal castings.

1. Machine Setup and Operation

Sets up and operates centrifugal casting machines according to established procedures.

- Loads molten metal into the casting machine.

- Controls the speed and temperature of the machine during the casting process.

2. Casting Inspection and Quality Control

Inspects castings for defects and ensures they meet quality standards.

- Checks the dimensions, surface finish, and other characteristics of the castings.

- Identifies and corrects any defects.

3. Machine Maintenance and Troubleshooting

Performs routine maintenance and troubleshooting on centrifugal casting machines.

- Lubricates and cleans the machine.

- Inspects and repairs mechanical and electrical components.

4. Safety and Compliance

Ensures a safe working environment and complies with all safety regulations.

- Wears appropriate personal protective equipment (PPE).

- Follows established safety procedures.

Interview Tips

To ace the interview for a Centrifugal Casting Machine Tender position, follow these preparation tips:

1. Research the Company and Position

Research the company’s products, services, and industry. Also, review the job description thoroughly to understand the specific duties and responsibilities of the role.

- Visit the company’s website to learn about their business.

- Read industry news and articles to stay informed about current trends.

2. Highlight Relevant Skills and Experience

Emphasize your skills and experiences that are relevant to the job requirements. For example, if the job description mentions casting inspection, highlight your experience in quality control or inspection.

- Quantify your accomplishments using specific metrics whenever possible.

- Provide concrete examples of your work to demonstrate your abilities.

3. Practice Answering Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience operating centrifugal casting machines.

- How do you ensure the quality of the castings you produce?

- How would you troubleshoot a problem with a centrifugal casting machine?

4. Dress Professionally and Arrive on Time

First impressions matter, so dress appropriately and arrive on time for your interview. This shows that you respect the interviewer’s time and that you are taking the opportunity seriously.

- Wear business attire that is clean and pressed.

- Be punctual and arrive for your interview 10-15 minutes early.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Centrifugal Casting Machine Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Centrifugal Casting Machine Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.