Feeling lost in a sea of interview questions? Landed that dream interview for Centrifugal Control Switch Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Centrifugal Control Switch Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

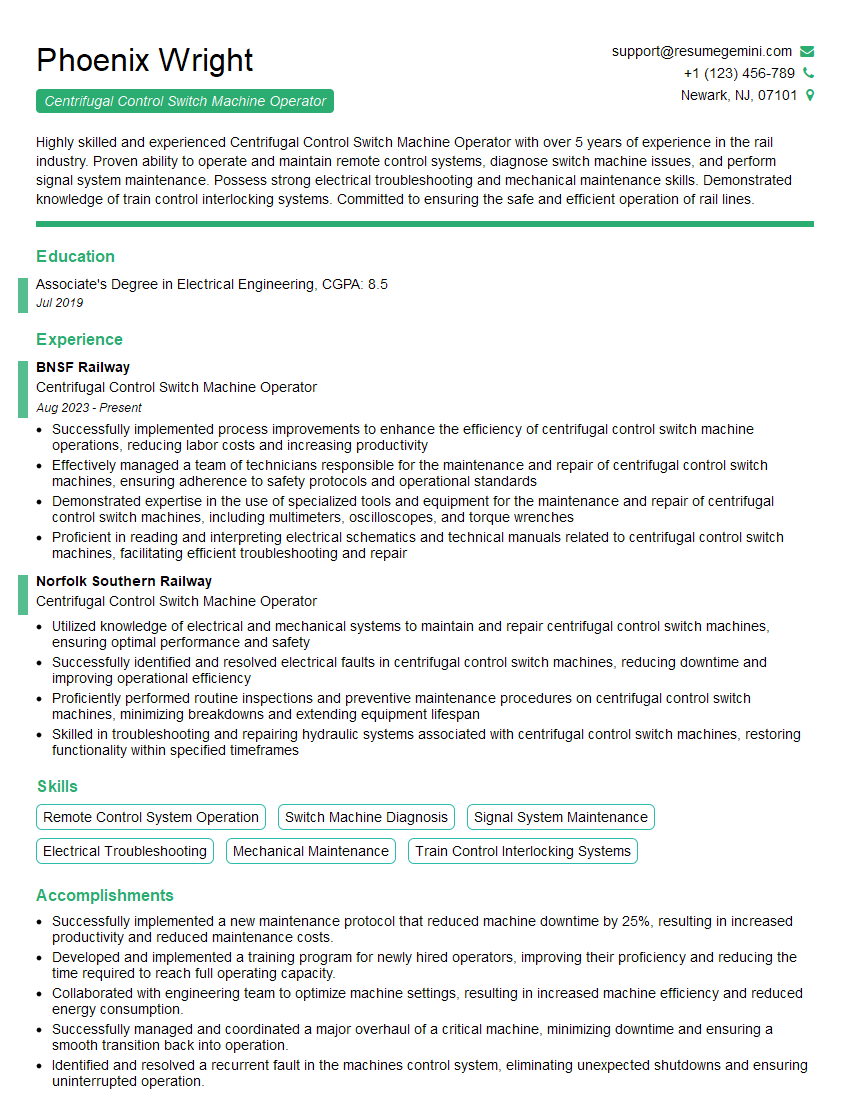

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Control Switch Machine Operator

1. What are the key responsibilities of a Centrifugal Control Switch Machine Operator?

As a Centrifugal Control Switch Machine Operator, my primary responsibilities include:

- Operating and maintaining centrifugal control switch machines for railroad track switches

- Ensuring proper alignment and functioning of switch points and frogs

- Monitoring and troubleshooting switch machine systems to prevent train derailments

- Performing routine inspections and maintenance on switch machines, including lubrication and electrical checks

- Following established safety protocols and procedures to minimize risks and ensure the well-being of myself and others

2. Describe the process of aligning and adjusting switch points and frogs using a centrifugal control switch machine.

Process of aligning switch points

- Receive instructions from the train dispatcher regarding the desired switch position

- Operate the centrifugal control switch machine to move the switch points to the correct alignment

- Check the alignment of the switch points using visual cues or measuring devices

- Make any necessary adjustments to ensure the switch points are aligned properly

Process of adjusting frogs

- Identify the frog that needs adjustment

- Use specialized tools or equipment to adjust the frog’s position and alignment

- Verify the adjustment by testing the switch machine’s operation

- Record the adjustment made and any observations in the maintenance log

3. How do you troubleshoot a centrifugal control switch machine that is not functioning properly?

When troubleshooting a centrifugal control switch machine, I follow a systematic approach:

- Identify the symptoms and observe the behavior of the switch machine

- Refer to technical documentation or consult with experienced colleagues for potential causes

- Check for loose connections, damaged wires, or other visible issues

- Use diagnostic tools or equipment to identify electrical or mechanical faults

- Determine the root cause of the problem and develop a plan for repairs or adjustments

- Implement the necessary repairs or adjustments to restore the switch machine to proper functioning

4. Explain the importance of maintaining proper lubrication on centrifugal control switch machines.

- Reduces friction and wear on moving parts, extending the lifespan of the switch machine

- Prevents corrosion and damage to metal components, ensuring reliable operation

- Ensures smooth and consistent movement of switch points and frogs, reducing the risk of derailments

- Facilitates regular inspections and maintenance, as lubricated parts are less likely to seize up or malfunction

- Contributes to overall safety and efficiency of the railroad system by minimizing downtime and potential accidents

5. Describe the safety precautions that must be taken when working on or near a centrifugal control switch machine.

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and high-visibility clothing

- Follow established lockout/tagout procedures to prevent accidental activation of the switch machine

- Be aware of the location of emergency stop buttons and evacuation routes

- Maintain a safe distance from moving parts and energized equipment

- Use proper lifting techniques and avoid working alone when handling heavy components

- Communicate with other personnel and train operators before performing any work on or near the switch machine

6. How do you stay up-to-date on the latest advancements and best practices in centrifugal control switch machine operation and maintenance?

- Attend industry conferences, workshops, and training programs

- Read technical articles, journals, and manufacturer’s manuals

- Participate in online forums and discussion groups

- Seek mentorship from experienced colleagues or supervisors

- Stay informed about regulatory updates and safety protocols related to switch machine operations

7. What is your approach to ensuring the reliability and uptime of centrifugal control switch machines?

- Implement a proactive maintenance schedule based on manufacturer’s recommendations

- Conduct regular inspections to identify potential issues early on

- Keep a detailed maintenance log to track repairs, adjustments, and observations

- Use predictive maintenance techniques, such as vibration monitoring, to anticipate and prevent failures

- Collaborate with supervisors and engineers to improve switch machine design and performance

8. Describe the role of a centrifugal control switch machine in preventing train derailments.

- Ensures the proper alignment of switch points and frogs

- Prevents trains from entering the wrong track or colliding with other trains

- Provides a reliable and efficient means of controlling train movement

- Contributes to the overall safety and integrity of the railroad infrastructure

- Helps maintain the smooth flow of rail traffic

9. Explain the difference between a centrifugal control switch machine and a spring switch.

Centrifugal control switch machine

- Uses centrifugal force to throw and lock the switch points

- Requires an external power source to operate

- Provides greater control and reliability over switch movement

Spring switch

- Uses a spring mechanism to throw and lock the switch points

- Does not require an external power source

- May be less reliable than centrifugal control switch machines in certain applications

10. What are the advantages of using digital technology in modern centrifugal control switch machines?

- Improves accuracy and precision of switch point alignment

- Enables remote monitoring and control of switch machines

- Provides real-time data on switch machine performance and maintenance needs

- Enhances safety by reducing human error and improving communication

- Contributes to the overall efficiency and optimization of railroad operations

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Control Switch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Control Switch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Centrifugal Control Switch Machine Operator

A Centrifugal Control Switch Machine Operator plays a vital role in ensuring safe and efficient railway operations. Their primary responsibilities include:

1. Operating Centrifugal Control Switch Machines

Operate, inspect, and maintain centrifugal control switch machines, which are used to control the movement of railroad switches and signals.

- Monitor and control the switching system to ensure safe and timely movement of trains.

- Inspect and troubleshoot switch machines, identifying and addressing any potential issues.

2. Maintaining Railway Equipment

Perform regular maintenance and repairs on various railway equipment, including tracks, signals, and switches.

- Inspect and repair tracks to ensure safe and smooth train operation.

- Maintain and calibrate signals to provide accurate information to train operators.

3. Ensuring Safety and Compliance

Adhere to strict safety regulations and procedures to ensure the safe operation of railway equipment.

- Follow all established safety guidelines and protocols.

- Report any potential hazards or safety concerns promptly.

4. Emergency Response

Respond effectively to railway emergencies, such as derailments or signal malfunctions.

- Coordinate with dispatchers and emergency personnel to ensure a swift and appropriate response.

- Implement emergency procedures to protect passengers, staff, and equipment.

Interview Preparation Tips for Centrifugal Control Switch Machine Operators

To ace an interview for a Centrifugal Control Switch Machine Operator position, candidates should consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the specific company and the role you are applying for. Understand their mission, values, and the responsibilities associated with the position.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about current trends and technologies.

2. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions, tailoring your answers to the specific job requirements. Consider using the STAR method (Situation, Task, Action, Result) to provide detailed examples of your skills and experiences.

- Describe a time when you successfully troubleshoot a complex railway issue and provide the result/outcome.

- Explain how you prioritize tasks and manage multiple responsibilities in a high-pressure environment.

3. Highlight Relevant Skills and Experience

Showcase your relevant skills and experiences that directly align with the job requirements. Emphasize your proficiency in operating centrifugal control switch machines, railway maintenance, and emergency response procedures.

- Quantify your achievements whenever possible, providing specific numbers and metrics.

- Be prepared to discuss your knowledge of railway safety regulations and industry best practices.

4. Be Enthusiastic and Confident

Demonstrate your passion for the railway industry and your eagerness to contribute to the company’s success. Maintain a positive and confident attitude throughout the interview.

- Express your interest in the role and explain why you are particularly suited for it.

- Be prepared to ask thoughtful questions to show your engagement and curiosity about the position and company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Centrifugal Control Switch Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.