Are you gearing up for a career in Centrifugal Drier Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Centrifugal Drier Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

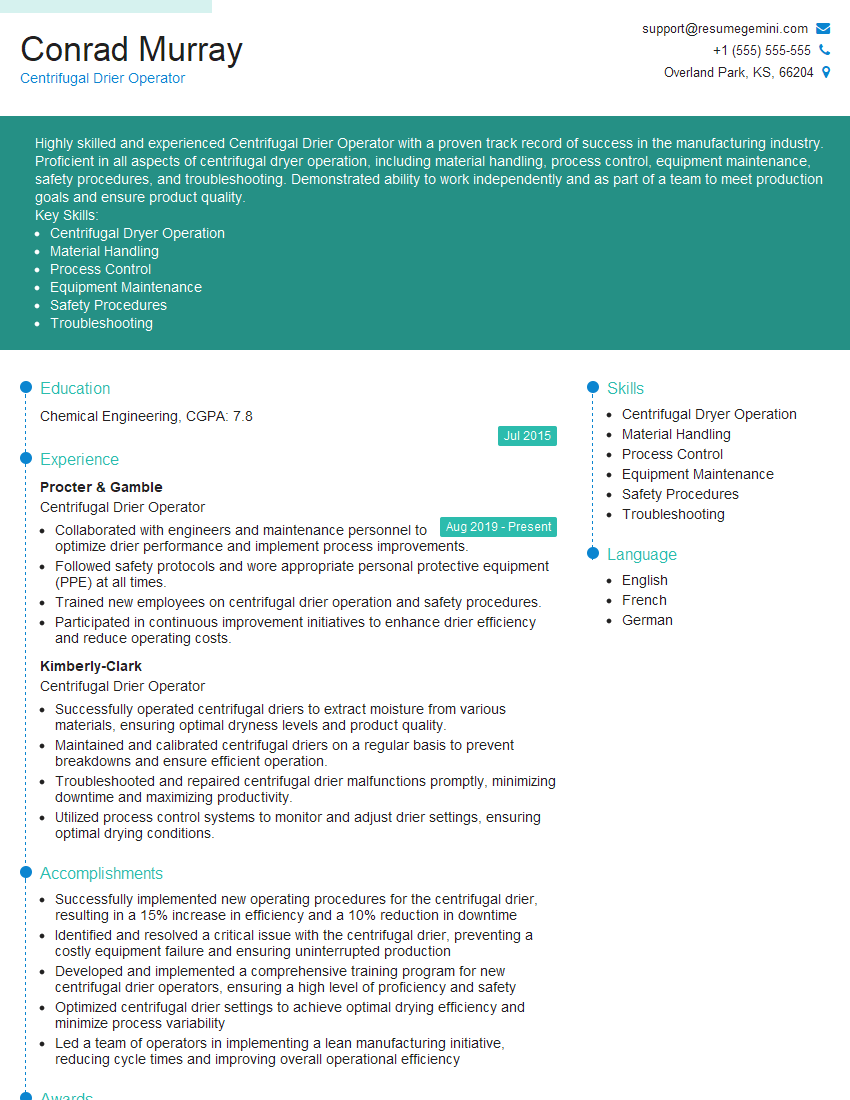

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Drier Operator

1. What are the key operational parameters to monitor and control during centrifugal drying operation?

- Feed rate

- Rotor speed

- Temperature

- Cycle time

- Vibration levels

2. Describe the steps involved in loading and unloading a centrifugal dryer.

Loading

- Check the dryer for any damage or contamination.

- Open the loading door and place the material to be dried inside the dryer.

- Close the loading door and secure it properly.

Unloading

- Stop the dryer and allow the rotor to come to a complete stop.

- Open the unloading door and remove the dried material.

- Clean the dryer and prepare it for the next cycle.

3. How do you maintain proper temperature and humidity levels inside a centrifugal dryer?

- Control the feed rate to prevent overloading and overheating.

- Monitor the temperature using thermocouples or other sensors.

- Adjust the ventilation rate to control humidity levels.

- Use a heating or cooling system to maintain the desired temperature.

- Inspect and clean the dryer regularly to prevent buildup of contaminants.

4. What are the potential safety hazards associated with centrifugal dryers?

- Explosion from drying flammable materials.

- Fire from overheating or electrical malfunctions.

- Rotor failure due to imbalance or fatigue.

- Chemical exposure from handling hazardous materials.

- Slips and falls on wet floors.

5. How do you troubleshoot common problems with centrifugal dryers?

- Vibration: Check rotor balance, bearings, and foundation.

- Overheating: Check feed rate, temperature sensors, and ventilation.

- Slow drying: Check feed rate, temperature, and humidity levels.

- Rotor failure: Inspect rotor for damage and check bearings.

- Electrical issues: Check wiring, motor, and controls.

6. What is the role of a variable frequency drive (VFD) in a centrifugal dryer?

- Controls the speed of the rotor.

- Improves energy efficiency by adjusting speed to match drying requirements.

- Reduces vibration and wear by optimizing rotor speed.

- Enhances safety by providing soft start and stop functions.

7. How do you ensure the quality of the dried product?

- Monitor drying parameters and make adjustments as needed.

- Inspect the dried product for moisture content, color, and other specifications.

- Perform regular maintenance and calibration of the dryer.

- Maintain records of drying conditions and product quality.

- Work closely with quality control personnel to meet customer requirements.

8. What is the difference between a batch and continuous centrifugal dryer?

- Processes material in batches.

- Requires loading and unloading between cycles.

- Suitable for small to medium production volumes.

- Processes material continuously.

- Material is fed and discharged while the rotor spins.

- Suitable for high production volumes.

Batch Centrifugal Dryer

Continuous Centrifugal Dryer

9. What are the different types of materials that can be dried in a centrifugal dryer?

- Chemicals

- Pharmaceuticals

- Foodstuffs

- Minerals

- Slurries

10. What are the advantages of using a centrifugal dryer?

- High drying capacity.

- Short drying cycles.

- Low energy consumption.

- Reduced product damage.

- Easy operation and maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Drier Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Drier Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Centrifugal Drier Operators play a crucial role in the industrial process, ensuring the efficient drying of solid materials using centrifugal force. Their main responsibilities encompass:

1. Equipment Operation and Maintenance

Operate and maintain centrifugal driers, adhering to established safety protocols and manufacturer guidelines.

- Monitor and adjust operational parameters such as temperature, speed, and feed rates.

- Perform regular maintenance checks, lubricate moving parts, and troubleshoot any technical issues promptly.

2. Material Handling

oversee the loading and unloading of materials into and from the centrifugal drier.

- Inspect materials for quality and ensure they meet specifications.

- Adjust feed rates to optimize drying efficiency and prevent blockages.

3. Product Quality Control

Monitor and ensure the quality of the dried product.

- Conduct regular product inspections to verify moisture content and other quality parameters.

- Make necessary adjustments to the drying process to meet quality standards.

4. Safety and Compliance

Uphold a safe and compliant work environment.

- Follow established safety procedures and wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area, adhering to industry regulations and environmental standards.

5. Collaboration and Communication

collaborate effectively with other team members and supervisors.

- Communicate operational updates, maintenance needs, and any concerns to relevant stakeholders.

- Participate in training programs to enhance knowledge and skills.

Interview Preparation Tips

Preparing for a Centrifugal Drier Operator interview is essential to showcase your qualifications and make a positive impression. Here are some valuable tips to help you ace the interview:

1. Research the Company and the Role

Familiarize yourself with the organization’s background, mission, and industry standing. Understand the specific requirements and responsibilities of the Centrifugal Drier Operator role.

- Visit the company’s website and social media pages.

- Read industry news and articles related to centrifugal drying.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining centrifugal driers. Quantify your experience and provide specific examples of how you have contributed to the efficient drying process.

- Describe your understanding of centrifugal drying principles and how you apply them in your work.

- Share examples of how you have optimized drying parameters to improve efficiency and product quality.

3. Demonstrate Your Quality Control Expertise

Highlight your ability to monitor and control the quality of dried products. Explain how you ensure compliance with specifications and industry standards.

- Discuss your experience in conducting product inspections and using testing equipment.

- Provide examples of how you have identified and resolved quality issues.

4. Showcase Your Safety and Compliance Consciousness

Emphasize your commitment to safety and compliance. Explain how you maintain a safe and compliant work environment.

- Describe your knowledge of relevant safety regulations and how you incorporate them into your daily work practices.

- Share examples of how you have promoted a culture of safety and environmental awareness in the workplace.

5. Prepare for Behavioral Interview Questions

Be prepared to answer behavioral interview questions that explore your problem-solving, teamwork, and communication skills.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Practice describing specific examples that demonstrate your abilities in these areas.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Centrifugal Drier Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Centrifugal Drier Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.