Feeling lost in a sea of interview questions? Landed that dream interview for Centrifugal Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Centrifugal Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

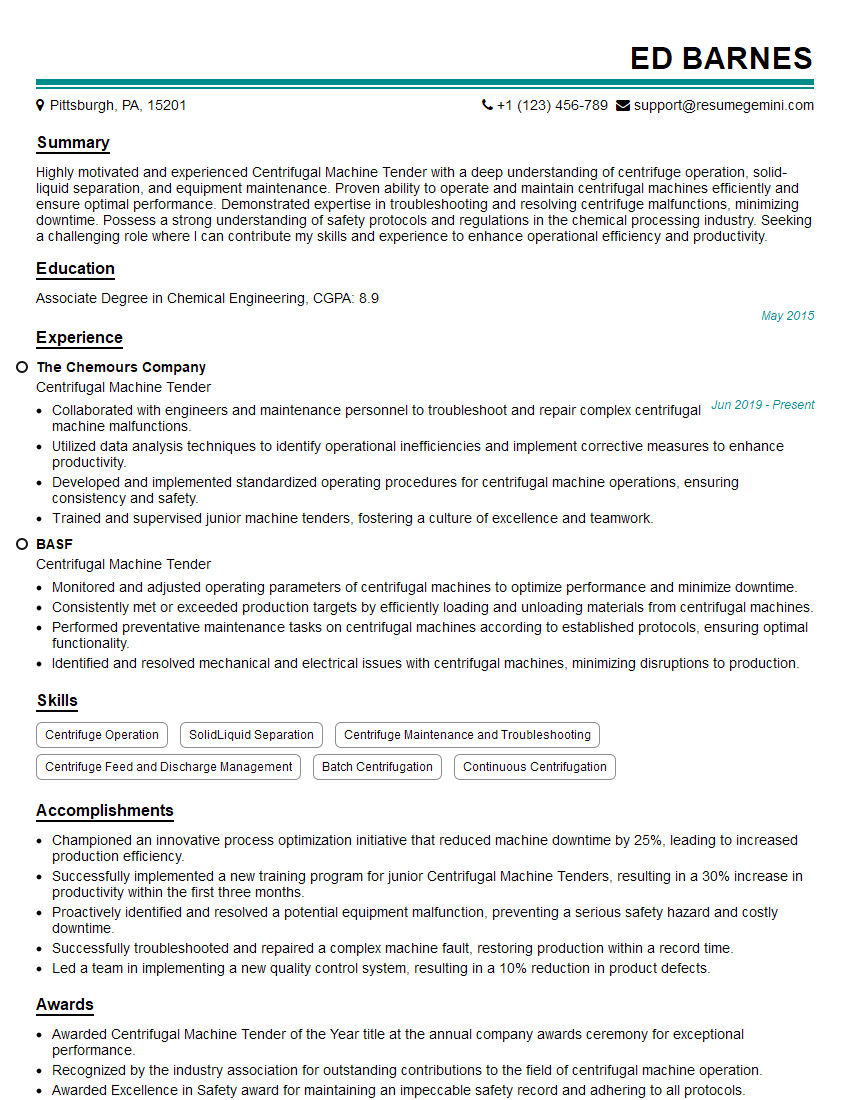

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Machine Tender

1. Explain the principles of centrifugal machine operation and the role of the centrifugal force in the separation process?

The centrifugal machine operates on the principle of centrifugal force, which is the outward force exerted on an object rotating about a central axis. In a centrifugal machine, a rotating basket or drum creates centrifugal force that separates particles of different densities within a liquid.

- As the basket or drum rotates, the heavier particles in the liquid are forced to the outer edge of the basket due to their greater inertia.

- The lighter particles, on the other hand, remain suspended in the inner portion of the basket.

- This difference in centrifugal force allows for the separation of particles based on their density.

2. Describe the different types of centrifugal machines, their applications, and the factors to consider when selecting a suitable machine for a specific application?

Types of Centrifugal Machines

- Solid Bowl Centrifuge: Separates solids from liquids, used in industries such as wastewater treatment, chemical processing, and food processing.

- Vertical Scroll Centrifuge: Similar to solid bowl centrifuge, but with a vertical orientation, allowing for higher solids content.

- Decanter Centrifuge: Used for continuous separation of solids from liquids, with a horizontal drum and scroll conveyor.

- Disc Centrifuge: High-speed centrifuge with a stack of thin discs, used for fine separation or clarification.

Factors to Consider When Selecting a Centrifugal Machine

- Feed characteristics (particle size, density, solids content)

- Separation requirements (target purity, separation efficiency)

- Capacity and throughput

- Space constraints and operational environment

3. Discuss the maintenance procedures for centrifugal machines, including lubrication, bearing inspection, and balancing?

- Lubrication: Regular lubrication of bearings and other moving parts is crucial to prevent wear and tear.

- Bearing Inspection: Bearings should be inspected regularly for any signs of damage or excessive wear.

- Balancing: Centrifugal machines must be balanced properly to minimize vibration and ensure smooth operation.

- Other Maintenance Tasks: Cleaning, inspecting seals, and monitoring temperature and vibration levels are also important maintenance practices.

4. Explain the safety precautions that must be followed when operating a centrifugal machine?

- Proper training and authorization are essential.

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Ensure the machine is properly grounded and electrically safe.

- Never operate the machine above its rated speed or capacity.

- Follow emergency procedures and shut down the machine safely in case of any issues.

5. Describe the troubleshooting procedures for common problems encountered with centrifugal machines, such as vibration, noise, and blockages?

Troubleshooting Vibration

- Check for unbalanced loads.

- Inspect bearings and couplings for wear or damage.

- Ensure the machine is properly leveled.

Troubleshooting Noise

- Check for loose parts or components.

- Inspect bearings and belts for wear or damage.

- Ensure the machine is properly lubricated.

Troubleshooting Blockages

- Check for foreign objects or excessive solids in the feed.

- Inspect discharge ports and screens for obstructions.

- Consider using a backflush or cleaning cycle to remove blockages.

6. Discuss the environmental impact of centrifugal machines and the measures that can be taken to minimize their environmental footprint?

- Energy Consumption: Centrifugal machines can consume a significant amount of energy. Using energy-efficient models and optimizing operating parameters can reduce energy consumption.

- Wastewater Generation: Some centrifugal machines generate wastewater. Proper disposal and treatment of wastewater is essential to minimize environmental impact.

- Noise and Vibration: Centrifugal machines can generate noise and vibration. Implementing soundproofing measures and isolating the machine can reduce these emissions.

7. Explain the importance of process control in centrifugal machine operation and the different control strategies that can be employed?

- Feed Rate Control: Maintaining a consistent feed rate is crucial for optimal separation efficiency.

- Speed Control: Adjusting the rotation speed of the machine can influence the separation process.

- Temperature Control: Temperature can affect the viscosity and density of the feed, necessitating temperature control.

- Automation: Advanced control systems can automate the operation of the centrifugal machine, improving efficiency and product quality.

8. Describe the use of centrifugal machines in specific industries, such as biotechnology, pharmaceuticals, and food processing?

Biotechnology

- Cell separation and purification

- Vaccine and therapeutic protein production

Pharmaceuticals

- Drug purification and crystallization

- API (Active Pharmaceutical Ingredient) isolation

Food Processing

- Fruit juice clarification

- Dairy product separation

- Wastewater treatment

9. Discuss the latest advancements and trends in centrifugal machine technology?

- Advanced Control Systems: AI and IoT-based control systems are improving efficiency and optimizing performance.

- Energy-Efficient Designs: Manufacturers are focusing on reducing energy consumption through innovative designs.

- Automated Cleaning and Maintenance: Automated systems are reducing maintenance downtime and improving hygiene.

- High-Speed Centrifuges: Ultra-high-speed centrifuges are enabling new applications in research and biotechnology.

10. How do you stay updated with the latest developments in centrifugal machine technology and industry best practices?

- Attending industry conferences and workshops

- Reading technical journals and publications

- Participating in online forums and discussion groups

- Consulting with manufacturers and experts in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Centrifugal Machine Tenders are responsible for operating and maintaining centrifugal machines that separate solids from liquids or gases. They perform a range of tasks to ensure the smooth and efficient operation of the machines, including:1. Machine Operation

- Starting, stopping, and monitoring the operation of centrifugal machines

- Adjusting machine settings to optimize performance

- Loading and unloading materials into and from the machine

- Collecting and disposing of waste materials

2. Machine Maintenance

- Performing routine maintenance tasks, such as cleaning, lubricating, and adjusting the machine

- Troubleshooting and resolving minor machine malfunctions

- Reporting major machine problems to supervisors for repair

3. Quality Control

- Monitoring the quality of the materials processed by the machine

- Taking corrective actions to ensure that the materials meet specifications

- Maintaining records of machine performance and quality control measures

4. Safety

- Following all safety procedures and guidelines

- Wearing appropriate safety gear

- Reporting any unsafe conditions or practices to supervisors

Interview Tips

Preparing thoroughly for an interview is essential to increase your chances of success. Here are some interview tips and hacks to help you ace your interview for a Centrifugal Machine Tender position:1. Research the Company and Industry

Research the company’s history, products, and services. This knowledge will demonstrate your interest and enthusiasm for the opportunity.2. Practice Your Answers to Common Questions

Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers out loud to improve your delivery.3. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in your resume and cover letter. Use specific examples to demonstrate your abilities, such as times you have successfully operated or maintained centrifugal machines.4. Dress Professionally

First impressions matter, so dress professionally for your interview. This shows that you respect the interviewer and the company.5. Arrive on Time

Punctuality indicates respect for the interviewer’s time. Plan your transportation and arrive for your interview a few minutes early.6. Be Enthusiastic and Positive

Maintain a positive and enthusiastic attitude throughout the interview. This will make you more engaging and memorable to the interviewer.7. Ask Questions

At the end of the interview, ask questions to demonstrate your interest and engagement. This could include questions about the company, the position, or the industry.8. Follow Up

After the interview, send a thank-you note to the interviewer. This is a simple way to reiterate your interest in the position and demonstrate your professionalism.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Centrifugal Machine Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.