Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Centrifuge Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

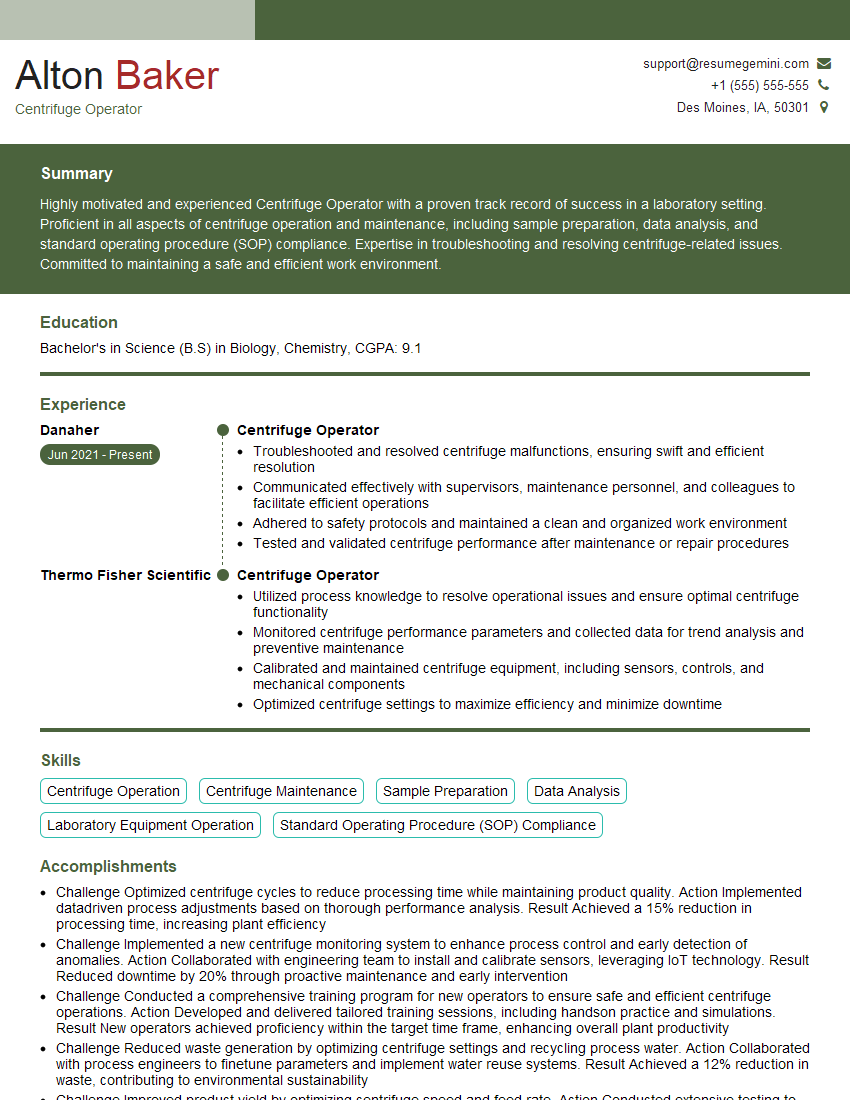

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifuge Operator

1. Explain the principle of centrifugation and how it is used to separate different substances?

- Centrifugation is the process of separating substances of different densities by spinning them at high speeds.

- The centrifugal force generated during spinning causes the denser particles to move towards the bottom of the centrifuge tube, while the less dense particles move towards the top.

- This difference in density allows for the separation of particles such as cells, proteins, and DNA.

2. Describe the different types of centrifuges and their applications?

Laboratory Centrifuges

- Used for small-scale separations in research and clinical laboratories.

- Types include microcentrifuges, clinical centrifuges, and refrigerated centrifuges.

Industrial Centrifuges

- Used for large-scale separations in industries such as food processing, pharmaceuticals, and wastewater treatment.

- Types include decanter centrifuges, disk stack centrifuges, and tubular centrifuges.

Ultracentrifuges

- Used for high-speed separations of subcellular particles and macromolecules.

- Can generate forces up to several hundred thousand times the force of gravity.

3. What safety precautions should be taken when operating a centrifuge?

- Ensure that the centrifuge is properly balanced before operating.

- Check the centrifuge regularly for any signs of damage or wear.

- Do not open the centrifuge lid while it is spinning.

- Use appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Follow the manufacturer’s instructions for safe operation and maintenance.

4. How do you calculate the centrifugal force generated by a centrifuge?

- Centrifugal force (CF) = (1.118 x 10^-5) x r x (rpm)^2

- Where: r is the radius of rotation in centimeters and rpm is the revolutions per minute.

5. Describe the different types of rotors used in centrifuges and their applications?

Fixed-Angle Rotors

- Hold tubes at a fixed angle, typically between 35 and 45 degrees.

- Used for general-purpose separations.

Swinging-Bucket Rotors

- Hold tubes in buckets that swing out horizontally during centrifugation.

- Used for gentler separations and for separating large volumes.

Vertical Rotors

- Hold tubes vertically, parallel to the axis of rotation.

- Used for high-speed separations, such as in ultracentrifuges.

6. What is the role of the brake in a centrifuge?

- The brake is used to stop the centrifuge rotor quickly after centrifugation.

- This prevents the rotor from spinning freely, which can cause damage to the centrifuge and its contents.

7. How do you maintain a centrifuge?

- Regularly clean the centrifuge chamber and rotor.

- Check the brushes and bearings for wear.

- Calibrate the centrifuge regularly to ensure accurate speed control.

- Follow the manufacturer’s recommended maintenance schedule.

8. What are some common troubleshooting tips for centrifuges?

- If the centrifuge is not spinning, check the power cord and fuse.

- If the centrifuge is vibrating excessively, check the balance of the rotor and samples.

- If the centrifuge is leaking, check the seals and gaskets.

- If the centrifuge is making strange noises, contact the manufacturer for assistance.

9. How do you determine the appropriate speed and time settings for centrifugation?

- The appropriate speed and time settings will depend on the sample and the desired separation.

- Consult the manufacturer’s guidelines or refer to scientific literature for recommended settings.

- Start with a low speed and gradually increase it until the desired separation is achieved.

10. What is the difference between relative centrifugal force (RCF) and gravitational force (g-force)?

- Relative centrifugal force (RCF) is the force exerted on a sample during centrifugation, relative to the force of gravity.

- Gravitational force (g-force) is the force exerted on an object due to gravity.

- RCF is typically expressed in multiples of g, where 1 g is equal to the force of gravity on Earth.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifuge Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifuge Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Centrifuge Operators are responsible for operating and monitoring centrifuges to separate liquids or solids. They work in a variety of industries, including manufacturing, petrochemical, and pharmaceutical.

1. Prepare and load centrifuges

Centrifuge Operators prepare and load centrifuges with the materials to be separated. They must ensure that the materials are properly loaded and that the centrifuge is operating correctly.

- Inspect and clean centrifuges before use

- Load materials into centrifuges according to specified procedures

2. Operate and monitor centrifuges

Centrifuge Operators operate and monitor centrifuges to ensure that they are operating correctly. They must be able to identify and correct any problems that may occur.

- Start and stop centrifuges

- Monitor centrifuge operation and make adjustments as needed

- Identify and correct any problems that may occur

3. Unload centrifuges

Centrifuge Operators unload centrifuges after the separation process is complete. They must ensure that the materials are properly unloaded and that the centrifuge is cleaned.

- Unload materials from centrifuges

- Clean centrifuges after use

4. Perform maintenance and repairs

Centrifuge Operators perform maintenance and repairs on centrifuges. They must be able to identify and correct any problems that may occur.

- Inspect and clean centrifuges regularly

- Identify and correct any problems that may occur

- Perform maintenance and repairs as needed

Interview Tips

Preparing for an interview for a Centrifuge Operator position involves understanding the key responsibilities of the role and practicing your answers to common interview questions related to your skills and experience. Here are some interview tips and preparation hacks to help you ace your interview:

1. Research the company and the position

Before you go into an interview, it’s important to do your research on the company and the specific position you’re applying for. This will help you understand the company’s culture and goals, and it will also give you a better idea of what the interviewer is looking for in a candidate.

- Visit the company’s website and read about their mission statement, values, and recent news.

- Check out the company’s social media pages to get a sense of their culture and what it’s like to work there.

- Read online reviews of the company to get feedback from current and former employees.

- Research the specific position you’re applying for. What are the key responsibilities?

- What are the qualifications and experience required? This information should be listed in the job description.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you’re likely to be asked in an interview for a Centrifuge Operator position. These questions may include:

- Tell me about your experience operating centrifuges.

- What are your strengths and weaknesses as a Centrifuge Operator?

- Why are you interested in working for our company?

- What are your salary expectations?

Take some time to prepare your answers to these questions before you go to your interview. This will help you feel more confident and prepared, and it will also show the interviewer that you’re serious about the position.

3. Practice your answers out loud

Once you’ve prepared your answers to common interview questions, it’s a good idea to practice them out loud. This will help you get comfortable with your answers and it will also help you identify any areas where you need to improve.

You can practice your answers with a friend or family member, or you can record yourself and listen back to your answers.

4. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. This means wearing a suit or business casual attire. You should also arrive on time for your interview. Punctuality shows that you’re respectful of the interviewer’s time.

5. Be confident and enthusiastic

Confidence is key in any interview, but it’s especially important in an interview for a Centrifuge Operator position. This is a physically demanding job, so the interviewer will be looking for someone who is confident in their abilities.

You should also be enthusiastic about the position. This shows the interviewer that you’re interested in the job and that you’re excited about the opportunity to work for the company.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Centrifuge Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Centrifuge Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.