Are you gearing up for an interview for a Centrifuge Separator Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Centrifuge Separator Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

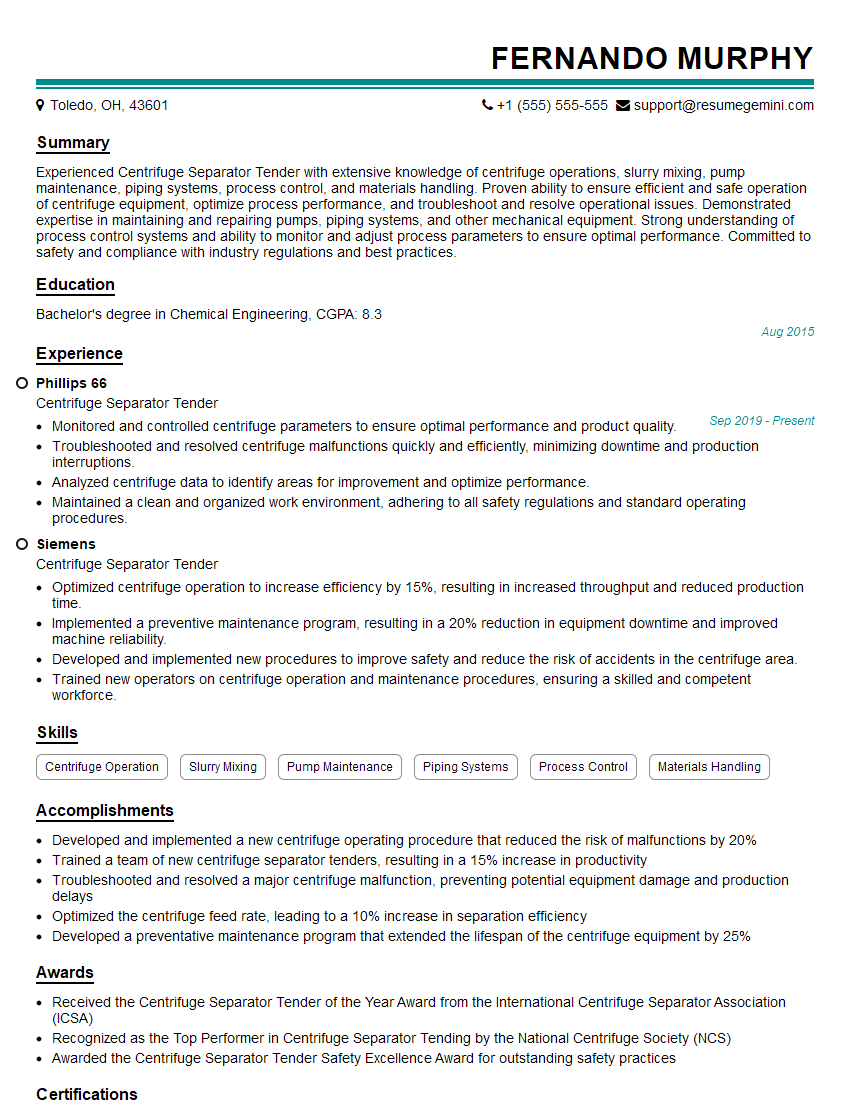

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifuge Separator Tender

1. Describe the principle of operation of a centrifuge separator?

The centrifuge separator works on the principle of centrifugal force, which separates solid particles from liquids or gases based on their density and size. The rotating motion of the separator creates a centrifugal force that causes heavier particles to move towards the outer rim of the equipment, while lighter particles remain in the center.

2. What are the key components of a centrifuge separator?

Mechanical Components

- Rotor: The rotating part of the separator that generates centrifugal force.

- Bowl: The housing that holds the rotor and contains the fluid mixture.

- Feed and Discharge Ports: Openings for introducing the mixture and removing the separated phases.

Control and Monitoring Systems

- Motor: Powers the rotor for centrifugal force generation.

- Controller: Regulates the motor speed and other operational parameters.

- Sensors: Monitor vibration, temperature, and other conditions.

3. What types of fluids can be separated using a centrifuge separator?

- Liquid-liquid mixtures, such as oil and water.

- Solid-liquid mixtures, such as sludge and wastewater.

- Gas-liquid mixtures, such as air and water in air pollution control systems.

4. What factors affect the efficiency of a centrifuge separator?

- Centrifugal force: Higher centrifugal force results in better separation.

- Viscosity and density of the fluids: Thicker and denser fluids require higher centrifugal force.

- Particle size and shape: Smaller and more irregular particles are harder to separate.

- Throughput rate: Higher throughput rates may reduce separation efficiency.

5. How do you maintain a centrifuge separator?

- Regular cleaning and inspection of the rotor, bowl, and other components.

- Monitoring and adjustment of operational parameters, such as speed and temperature.

- Lubrication of moving parts to minimize wear and tear.

- Preventive maintenance tasks as recommended by the manufacturer.

6. What safety precautions should be taken while operating a centrifuge separator?

- Wear protective clothing and safety glasses.

- Ensure the separator is properly grounded and balanced.

- Do not open the bowl or access the rotor while the machine is in operation.

- Follow all manufacturer’s safety guidelines and training.

7. How do you troubleshoot common problems with a centrifuge separator?

- Excessive vibration: Indicates imbalance, bearing wear, or other mechanical issues.

- Poor separation: Can be caused by factors affecting efficiency, such as viscosity or density changes.

- Leaking: May indicate worn seals or gaskets, or a problem with the bowl.

- Electrical faults: Motor or control issues that need electrical troubleshooting.

8. What is the difference between a disk stack centrifuge and a tubular bowl centrifuge?

- Disk Stack Centrifuge: Uses a stack of disks to create centrifugal force and separate fluids.

- Tubular Bowl Centrifuge: Has a cylindrical bowl that rotates to generate centrifugal force and separate fluids.

9. How do you calculate the centrifugal force generated by a centrifuge separator?

Centrifugal force = (Mass x Velocity²) / Radius

- Mass: Weight of the fluid being separated.

- Velocity: Tangential velocity of the rotor.

- Radius: Distance from the axis of rotation to the outer rim.

10. What is the role of chemical additives in centrifuge separation?

- Flocculants: Enhance particle aggregation for improved separation.

- Coagulants: Neutralize charges and promote particle bonding.

- Demulsifiers: Break down emulsions for better separation of liquids.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifuge Separator Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifuge Separator Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Centrifuge Separator Tender, your primary duties will revolve around the operation, maintenance, and repair of centrifuge separators used in various industries. Your main focus will be on ensuring the smooth and efficient separation of liquids and solids through centrifugal force.

1. Operation

You will be responsible for overseeing the daily operation of centrifuge separators, including:

- Monitoring equipment performance and adjusting parameters to optimize separation

- Loading and unloading materials into and from the centrifuge

- Ensuring proper feed rates and product quality

2. Maintenance and Repair

Regular maintenance and repairs are crucial to ensure the optimal performance of centrifuge separators. Your duties in this area will include:

- Performing routine inspections and cleaning

- Replacing worn or damaged parts

- Troubleshooting and resolving mechanical and electrical issues

- Maintaining detailed records of maintenance and repairs

3. Safety and Compliance

Safety is paramount in any industrial setting. As a Centrifuge Separator Tender, you are responsible for:

- Adhering to all safety protocols and regulations

- Using personal protective equipment (PPE) at all times

- Maintaining a clean and organized work area

- Reporting any safety concerns or incidents promptly

4. Training and Development

Continuous training and development are essential for staying abreast of the latest industry advancements. Your responsibilities in this regard include:

- Participating in training programs and workshops

- Staying informed about new technologies and best practices

- Sharing knowledge with colleagues and promoting a culture of continuous improvement

Interview Tips

To ace an interview for a Centrifuge Separator Tender position, consider the following tips:

1. Preparation

Thoroughly review the job description and identify the key requirements. Research the company and its industry to demonstrate your understanding of their operations.

- Example: “I noticed in the job description that you emphasize safety. I am committed to maintaining a safe and compliant work environment, as evidenced by my OSHA certification and experience with safety protocols in previous roles.”

2. Experience and Skills

Highlight your previous experience in operating, maintaining, or repairing centrifuge separators. Quantify your accomplishments with specific metrics whenever possible.

- Example: “In my previous role, I increased centrifuge efficiency by 15% through optimized maintenance schedules and predictive analysis, resulting in significant cost savings for the company.”

3. Industry Knowledge

Demonstrate your knowledge of the industry and its applications. Discuss your understanding of different types of centrifuge separators and their use in various industries.

- Example: “I have experience working with both disc-stack and scroll-type centrifuges, and I am familiar with their applications in the oil and gas, pharmaceutical, and food processing industries.”

4. Safety and Regulations

Emphasize your commitment to safety and compliance. Highlight your knowledge of relevant regulations and safety protocols, such as OSHA standards or industry-specific guidelines.

- Example: “I am well-versed in OSHA regulations and have implemented safety programs that resulted in a reduction of accidents by 20% in my previous workplace.”

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Centrifuge Separator Tender, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Centrifuge Separator Tender positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.