Feeling lost in a sea of interview questions? Landed that dream interview for Ceramic Artist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ceramic Artist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

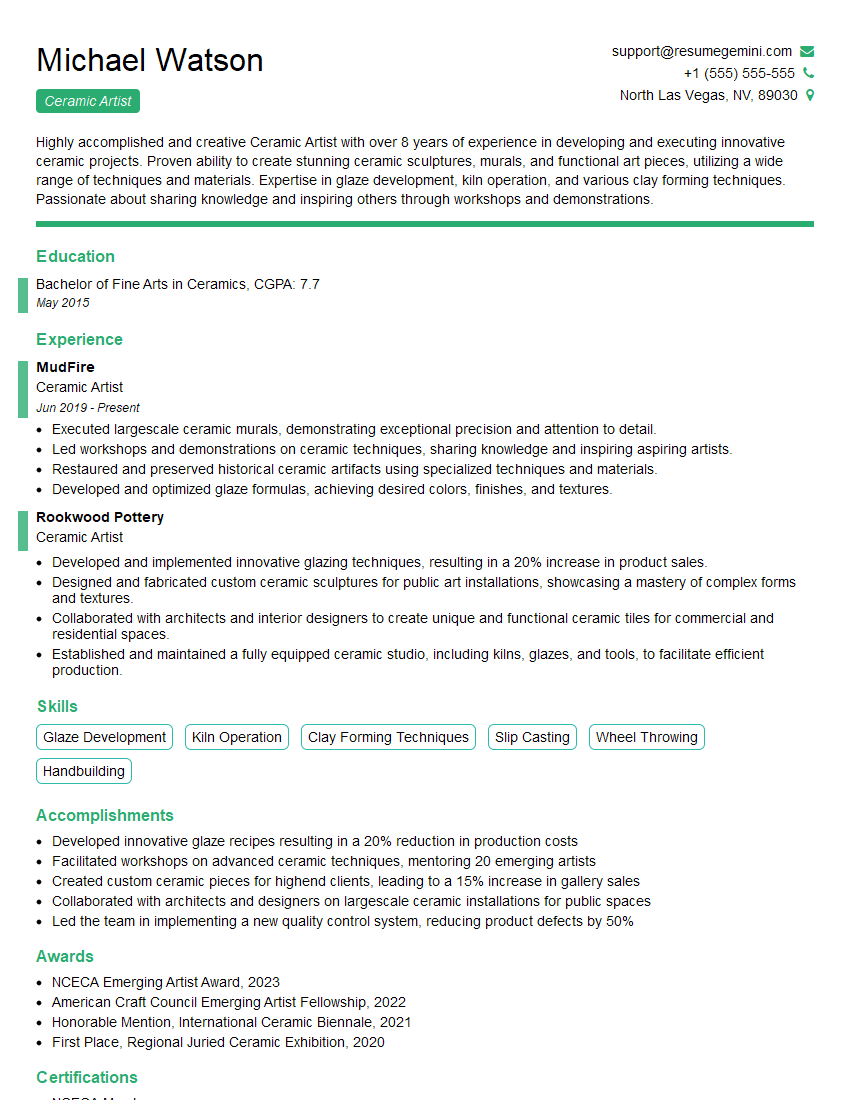

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Artist

1. Explain the process of creating a ceramic piece from start to finish?

The process of creating a ceramic piece from start to finish involves several stages:

- Clay Preparation: Selecting and preparing the appropriate clay body, which can include mixing, wedging, and de-airing to remove air bubbles.

- Forming: Shaping the clay into the desired form using techniques such as hand-building, wheel-throwing, or slip-casting.

- Drying: Allowing the formed clay to dry slowly and evenly to prevent cracking or warping.

- Bisque Firing: Firing the dried piece in a kiln to a low temperature to harden it and remove any remaining moisture.

- Glazing (Optional): Applying a liquid glass material to the bisqued piece to create a protective and decorative surface.

- Glaze Firing: Firing the glazed piece in a kiln at a higher temperature to melt and fuse the glaze to the ceramic.

2. What are the different types of clay bodies, and how do their properties influence the finished ceramic piece?

Physical Properties:

- Plasticity: The clay’s ability to be deformed without cracking, which affects its workability and ability to hold shape.

- Firing range: The temperature range at which the clay can be fired without melting or deforming.

- Porosity: The amount of water the fired ceramic absorbs, which affects its strength, durability, and thermal conductivity.

Chemical Properties:

- Mineral composition: The types and proportions of minerals present in the clay, which can influence its color, texture, and firing characteristics.

- Additives: Materials that can be added to the clay to modify its properties, such as grog (crushed fired clay) for texture or flux (glass-forming materials) for lower firing temperatures.

3. Describe the different firing techniques used in ceramics and their impact on the final product?

- Oxidation Firing: Firing in a kiln with sufficient oxygen to create an oxidizing atmosphere, resulting in reddish or brown colors and a porous finish.

- Reduction Firing: Firing in a kiln with limited oxygen to create a reducing atmosphere, producing dark grays or blacks and a more vitreous finish.

- Salt Firing: Introducing salt into the kiln during firing, which creates a vapor that interacts with the clay surface to produce a range of colors and textures.

- Wood Firing: Firing in a kiln with wood fuel, resulting in unique colorations and patterns due to the ash and smoke interacting with the clay.

4. How do you control the shrinkage and warping of a ceramic piece during the firing process?

- Proper Drying: Drying the piece slowly and evenly to prevent uneven shrinkage and warping.

- Appropriate Firing Schedule: Using a gradual heating and cooling cycle in the kiln to minimize thermal stress.

- Clay Body Selection: Choosing a clay body with low shrinkage and good thermal stability.

- Balanced Construction: Ensuring that the piece is evenly built and has a symmetrical structure.

- Kiln Supports: Placing the piece on supports in the kiln to prevent sagging or deformation.

5. How do you troubleshoot common ceramic defects, such as cracks, pinholes, or glaze crazing?

- Cracks: Incorrect drying or firing schedules, improper clay preparation, or excessive moisture in the clay.

- Pin holes: Air bubbles trapped in the clay, insufficient bisque firing temperature, or incompatible glaze and clay body.

- Glaze crazing: Differences in the thermal expansion rates of the glaze and clay body, over-firing, or using a glaze with too high a coefficient of expansion.

- Solutions: Adjust drying and firing schedules, ensure thorough clay preparation, remove air bubbles during forming, use compatible materials, and test glazes for compatibility.

6. How do you use colorants, glazes, and other materials to achieve specific aesthetic effects in your ceramic work?

- Colorants: Using metal oxides, pigments, or stains to introduce color into the clay or glaze.

- Glazes: Applying a glass-like coating to the ceramic surface to create a variety of colors, textures, and finishes.

- Underglazes: Applying colored pigments or stains beneath the glaze to create designs or patterns.

- Slip: Using a liquid clay mixture to create decorative patterns or textures on the ceramic surface.

7. How do you incorporate sustainability practices into your ceramic art?

- Sustainable Clay Sources: Using clays from renewable sources or recycled materials.

- Energy-Efficient Kilns: Investing in kilns with energy-saving features to reduce energy consumption.

- Waste Reduction: Minimizing waste by reusing clay scraps, recycling materials, and composting organic matter.

- Eco-Friendly Glazes: Using glazes with low toxicity and low environmental impact.

- Sustainable Packaging: Using biodegradable or recyclable packaging materials.

8. How do you stay updated on the latest trends and techniques in the field of ceramics?

- Workshops and Classes: Attending workshops and classes to learn new techniques and expand knowledge.

- Ceramic Journals and Publications: Reading industry journals, magazines, and books to stay informed.

- Conferences and Exhibitions: Participating in ceramic conferences and exhibitions to connect with other artists and learn about innovations.

- Online Resources: Exploring online forums, websites, and social media platforms dedicated to ceramics.

9. How do you balance your artistic vision with the functional requirements of ceramic art?

- Understanding the Purpose: Considering the intended use and environment of the ceramic piece.

- Design Modifications: Adapting artistic concepts to ensure functionality, such as modifying shapes or adding handles.

- Material Selection: Choosing clays and glazes that are durable and suitable for the desired application.

- Testing and Feedback: Creating prototypes, conducting user testing, and incorporating feedback to enhance functionality.

10. How do you handle criticism and feedback on your ceramic work?

- Constructive Feedback: Approaching criticism as an opportunity for growth and improvement.

- Openness to Suggestions: Listening attentively to feedback and considering alternative perspectives.

- Professionalism: Responding respectfully and maintaining a positive attitude.

- Integration and Evolution: Incorporating valid criticism into future work to refine and evolve artistic practice.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Artist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Artist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A ceramic artist is responsible for the creation of artistic and functional objects from ceramic materials. They use a variety of techniques to shape, glaze, and fire clay, porcelain, and other ceramic materials. Key job responsibilities include:

1. Developing and executing original artwork

Ceramic artists conceive and design original artwork, taking into account the properties of different ceramic materials and the desired aesthetic effect. They use a variety of techniques to create their work, including hand-building, wheel-throwing, and glazing.

2. Glazing and firing ceramics

Ceramic artists apply glazes to their work to create a variety of surface finishes. They also fire their work in kilns to harden the clay and fuse the glaze. The firing process can be complex and requires careful attention to temperature and timing.

3. Marketing and selling artwork

Ceramic artists often market and sell their work through galleries, online stores, and art fairs. They may also teach workshops or give lectures on their work.

4. Maintaining a studio space

Ceramic artists typically work in a studio space that is equipped with the tools and materials they need to create their work. They are responsible for maintaining their studio space and keeping it clean and organized.

Interview Tips

Preparing for an interview for a ceramic artist position can be daunting, but with the right preparation, you can increase your chances of making a positive impression on the hiring manager. Here are some tips to help you ace your interview:

1. Research the company and the position

Before you go on an interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Bring a portfolio of your work

A portfolio of your work is an essential part of any interview for a ceramic artist position. Your portfolio should showcase your best work and demonstrate your range of skills and techniques. Be sure to bring a variety of pieces that represent your different styles and interests.

4. Be prepared to talk about your experience

The interviewer will want to know about your experience as a ceramic artist. Be prepared to discuss your training, your previous work experience, and any relevant skills or knowledge that you have. You should also be able to talk about your artistic process and your inspiration.

5. Be enthusiastic and professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are passionate about your work and that you are serious about the position. Be polite and respectful, and make eye contact with the interviewer when you are speaking.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramic Artist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!