Feeling lost in a sea of interview questions? Landed that dream interview for Ceramic Capacitor Processor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Ceramic Capacitor Processor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

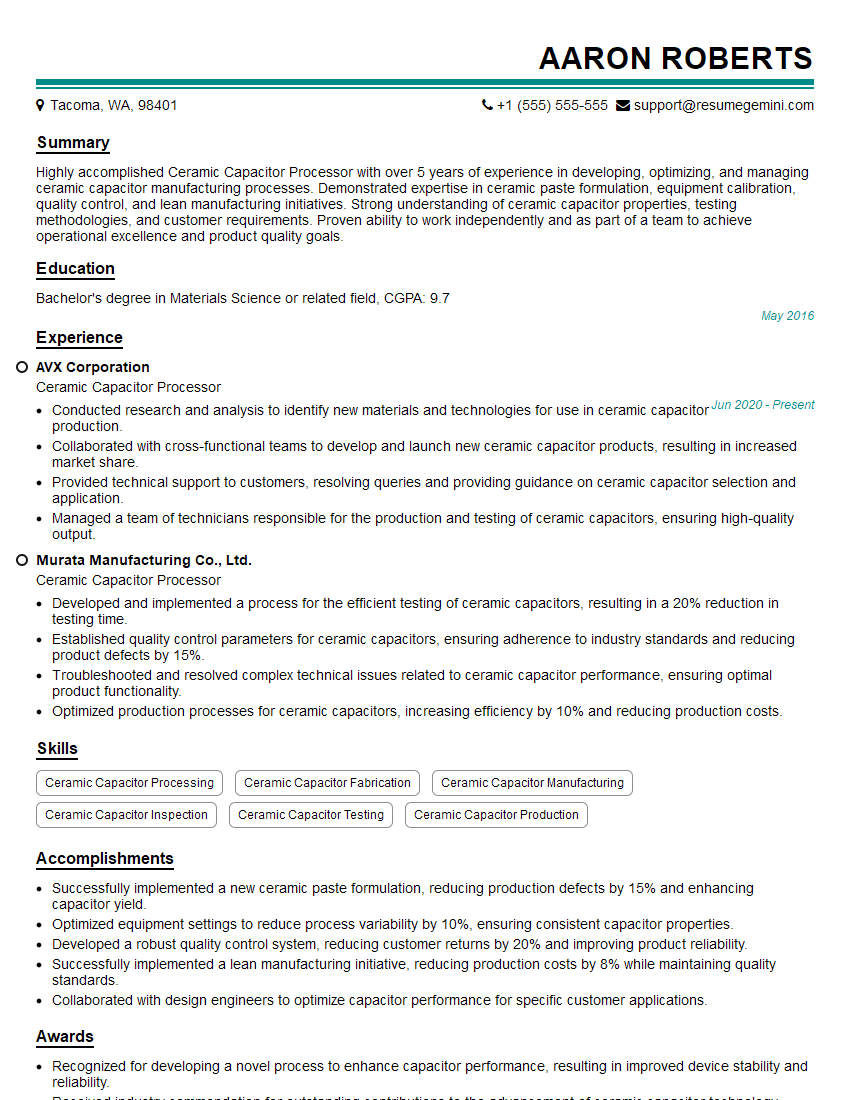

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Capacitor Processor

1. How do you determine the capacitance of a ceramic capacitor?

To determine the capacitance of a ceramic capacitor, we need to consider the following factors:

- Physical dimensions: The capacitance is proportional to the area of the capacitor plates and inversely proportional to the distance between them.

- Dielectric material: The dielectric material between the plates influences the capacitance. Different materials have different dielectric constants (k).

- Electrode material: The material of the capacitor electrodes (e.g., silver, gold) also affects the capacitance.

- Manufacturing process: The specific manufacturing process can introduce variations in capacitance.

2. What are the advantages and disadvantages of using ceramic capacitors?

Advantages

- High capacitance values in small form factors

- Low cost

- Stable performance over a wide temperature range

- Excellent high-frequency characteristics

Disadvantages

- Lower accuracy compared to other capacitor types

- Non-linear capacitance-voltage relationship

- Susceptibility to voltage derating at high temperatures

- Can be sensitive to moisture and mechanical stress

3. What are the different types of ceramic capacitors and their applications?

There are several types of ceramic capacitors, each with its own unique characteristics and applications:

- Class 1: High stability, used in resonant circuits, filters, and timing applications.

- Class 2: General-purpose, used in decoupling, filtering, and noise suppression applications.

- Class 3: High capacitance, used in power supply filtering and energy storage applications.

- High-voltage ceramic capacitors: Designed for high-voltage applications, such as power electronics and ignition systems.

- Multilayer ceramic capacitors (MLCCs): Compact, high-capacitance capacitors used in a wide range of electronic devices.

4. How do you test the quality of a ceramic capacitor?

The quality of a ceramic capacitor can be assessed through various tests, including:

- Capacitance measurement: Verifies the capacitance value within specified tolerances.

- Insulation resistance measurement: Ensures proper insulation between capacitor terminals.

- Voltage withstand test: Evaluates the capacitor’s ability to withstand specified voltage levels.

- Temperature cycling test: Tests the capacitor’s stability and performance over various temperature ranges.

- Vibration and shock test: Assesses the capacitor’s tolerance to mechanical stress.

5. What are the factors that can affect the lifespan of a ceramic capacitor?

Factors that can impact the lifespan of a ceramic capacitor include:

- Operating voltage: Exceeding voltage ratings can shorten capacitor life.

- Temperature: High temperatures can accelerate degradation.

- Moisture: Moisture ingress can lead to capacitor failure.

- Mechanical stress: Excessive vibration or shock can damage the capacitor.

- Manufacturing defects: Faulty materials or production processes can compromise the capacitor’s lifespan.

6. What are the challenges in manufacturing high-quality ceramic capacitors?

Manufacturing high-quality ceramic capacitors involves several challenges:

- Material purity: Impurities in the ceramic material can affect capacitor performance.

- Precision processing: Precise control of the capacitor’s dimensions and shape is essential.

- Electrode deposition: Ensuring uniform and reliable electrode deposition is crucial.

- Quality control: Robust testing and quality control measures are necessary to maintain product consistency.

- Cost-effective production: Balancing performance requirements with cost considerations is a key challenge.

7. How do you keep up with the latest advancements in ceramic capacitor technology?

To stay updated with the latest advancements in ceramic capacitor technology, I actively engage in the following practices:

- Attend industry conferences and workshops: These events provide opportunities to learn about new developments and network with experts.

- Read technical journals and articles: I regularly review academic and industry publications to stay informed about research and innovation.

- Participate in online forums and discussions: Engaging with industry professionals online allows me to exchange ideas and stay abreast of trends.

- Collaborate with research institutions: Partnering with universities or research institutes provides access to cutting-edge research and development projects.

8. What is the role of simulation and modeling in the design of ceramic capacitors?

Simulation and modeling play a vital role in the design of ceramic capacitors by enabling us to:

- Predict performance: Simulate capacitor performance under different operating conditions, such as voltage, frequency, and temperature.

- Optimize design: Iterate through design parameters to find the optimal combination for desired performance.

- Identify potential issues: Simulate various scenarios to identify potential problems that may arise in real-world applications.

- Reduce development time: Simulation helps minimize the need for physical prototyping and testing, saving time and resources.

9. How do you ensure that ceramic capacitors meet industry standards and regulations?

To ensure compliance with industry standards and regulations, I adhere to the following practices:

- Familiarity with standards: I stay up-to-date with relevant industry standards and regulatory requirements.

- Quality control: Implement rigorous quality control procedures throughout the manufacturing process to meet established specifications.

- Third-party testing: Engage with accredited testing laboratories to verify compliance with standards and regulations.

- Documentation and traceability: Maintain comprehensive documentation and records to demonstrate compliance and traceability.

10. How do you handle customer inquiries and complaints regarding ceramic capacitor products?

When addressing customer inquiries and complaints, I prioritize the following steps:

- Active listening: I listen attentively to understand the customer’s concerns and gather relevant information.

- Troubleshooting: I work with the customer to troubleshoot the issue, identify the root cause, and propose potential solutions.

- Technical support: I provide technical support to assist customers in understanding capacitor performance and application.

- Product replacement: If necessary, I facilitate product replacement or repair to resolve the issue.

- Follow-up: I follow up with customers to ensure their satisfaction and gather feedback for continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Capacitor Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Capacitor Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramic Capacitor Processors are responsible for the production, testing, and inspection of ceramic capacitors. They play a crucial role in ensuring the quality and reliability of these components, which are vital for various electronic devices.

1. Manufacturing and Assembly

– Monitor and control assembly and production lines to ensure efficient and accurate manufacturing of ceramic capacitors.

- Operate and maintain automated equipment for capacitor fabrication, including pressing, sintering, and coating.

- Inspect capacitors throughout the manufacturing process, identifying and correcting defects.

2. Testing and Inspection

– Conduct electrical testing on capacitors to measure capacitance, leakage current, and other electrical parameters.

- Interpret test results and analyze data to identify any deviations or failures.

- Maintain and calibrate testing equipment to ensure accuracy and reliability.

3. Quality Control and Process Improvement

– Implement quality control measures to ensure product specifications are met and customer requirements are exceeded.

- Monitor production processes and identify areas for improvement.

- Collaborate with engineers and technicians to troubleshoot issues and optimize manufacturing methods.

4. Compliance and Documentation

– Ensure compliance with industry standards, regulations, and customer specifications.

- Maintain detailed records and documentation related to production processes, testing results, and quality control measures.

- Respond to customer inquiries and provide technical support on ceramic capacitor products.

Interview Tips

Preparing effectively for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for a Ceramic Capacitor Processor position:

1. Research the Company and Position

– Gather as much information as possible about the company, its products, and the specific role you are applying for.

- Visit the company website, read industry news, and connect with current or former employees on LinkedIn.

- Carefully review the job description and identify the key skills and experience required.

2. Highlight Relevant Skills and Experience

– Emphasize your technical skills in ceramic capacitor manufacturing, testing, and quality control.

- Quantify your accomplishments and provide specific examples of your contributions to previous projects or roles.

- Demonstrate your ability to solve problems, analyze data, and improve processes.

3. Prepare for Common Interview Questions

– Practice answering common interview questions related to your technical skills, experience, and career goals.

- For example, you may be asked about your knowledge of capacitor manufacturing processes or your experience in troubleshooting quality issues.

- Also, prepare questions to ask the interviewer, showing your interest in the company and the position.

4. Dress Professionally and Arrive on Time

– First impressions matter, so dress professionally and arrive at the interview on time.

- Be respectful of the interviewer’s time and follow any instructions provided.

- Maintain a positive and enthusiastic attitude throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramic Capacitor Processor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!