Are you gearing up for an interview for a Ceramic Coater position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ceramic Coater and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

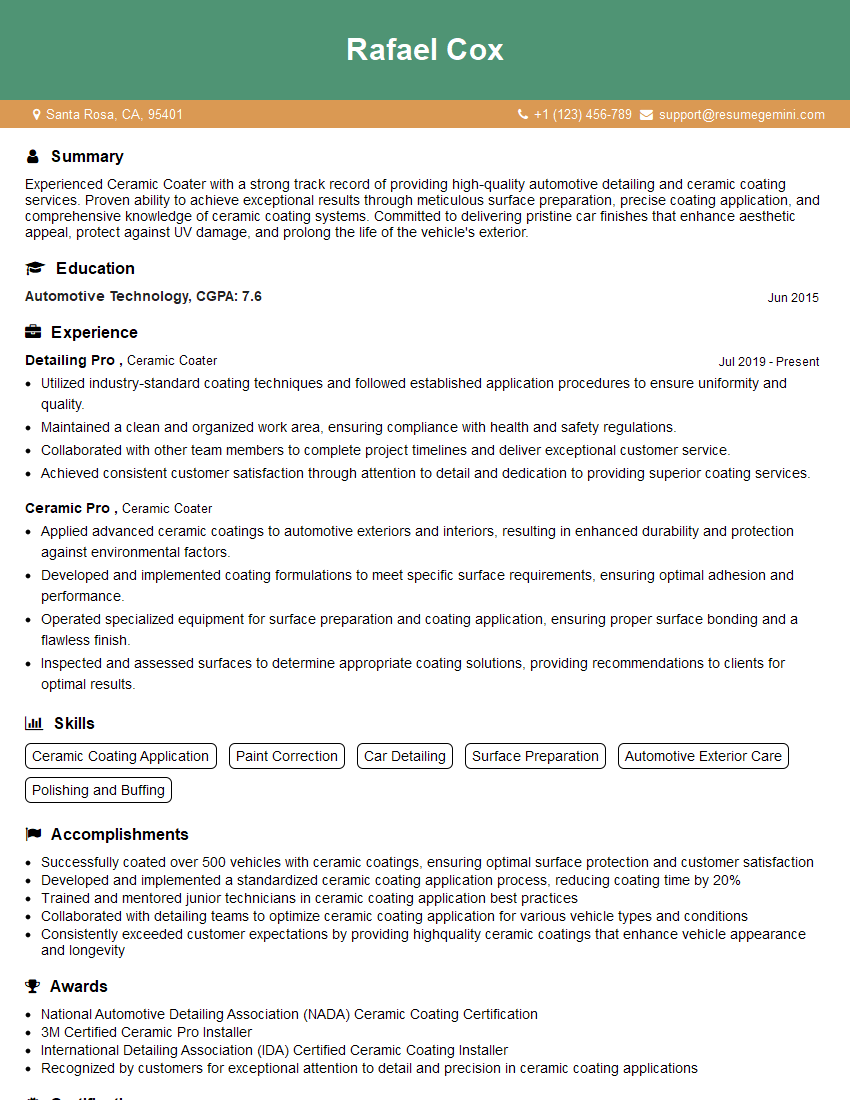

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Coater

1. What are the different types of ceramic coatings and their applications?

- Anti-Fouling Coatings: Used to prevent the growth of marine organisms on ship hulls.

- Abrasion-Resistant Coatings: Used to protect surfaces from wear and tear, such as in industrial machinery.

- Thermal Barrier Coatings: Used to protect surfaces from extreme heat, such as in jet engines.

- Corrosion-Resistant Coatings: Used to protect surfaces from corrosion, such as in pipelines.

- Electrical Coatings: Used to provide electrical insulation or conductivity, such as in electronic devices.

2. How do you determine the appropriate ceramic coating for a specific application?

Factors to Consider

- Substrate material

- Service environment

- Desired performance characteristics (e.g., wear resistance, corrosion resistance)

- Cost

Process

- Assess the application requirements and identify the key performance criteria.

- Review different ceramic coating options and their properties.

- Conduct testing or consult with experts to validate the coating’s suitability for the application.

- Select the most appropriate coating based on technical and economic considerations.

3. Explain the ceramic coating application process in detail.

- Surface Preparation: Cleaning, degreasing, and roughening the surface to enhance coating adhesion.

- Coating Application: Applying the ceramic powder or suspension using techniques like spraying, dipping, or spin coating.

- Drying: Removing excess moisture or solvents from the coating.

- Curing: Heating the coated surface to solidify the coating and develop its desired properties.

- Post-Treatment: Additional steps, such as polishing or annealing, may be necessary to optimize coating performance.

4. How do you ensure the quality of ceramic coatings?

- Adhesion Testing: Assessing the bond strength between the coating and substrate.

- Thickness Measurement: Verifying the coating thickness meets specifications.

- Hardness Testing: Evaluating the coating’s resistance to deformation and wear.

- Corrosion Testing: Exposing the coating to corrosive environments to assess its protective capabilities.

- Visual Inspection: Examining the coating’s surface for defects or imperfections.

5. What are the common challenges encountered in ceramic coating and how do you overcome them?

- Substrate Compatibility: Ensuring the ceramic coating adheres well to the substrate material.

- Coating Thickness Optimization: Balancing coating thickness with performance and durability requirements.

- Process Optimization: Adjusting coating application parameters (e.g., temperature, time) to achieve optimal results.

- Defects and Imperfections: Minimizing defects and imperfections that may compromise coating performance.

- Environmental Regulations: Complying with environmental regulations related to coating materials and processes.

6. How do you stay updated on the latest advancements in ceramic coating technology?

- Industry Events and Conferences: Attending industry events and conferences to learn about new technologies and trends.

- Technical Publications and Journals: Reading scientific journals and industry publications to stay informed of research and developments.

- Online Resources: Utilizing online platforms, forums, and websites to access technical information and connect with experts.

- Manufacturer Updates: Subscribing to manufacturer newsletters and updates to receive information on new products and advancements.

- Continuing Education: Participating in workshops, webinars, or online courses to enhance knowledge and skills.

7. How can ceramic coatings benefit different industries?

- Automotive Industry: Enhanced scratch resistance, corrosion protection, and thermal management.

- Aerospace Industry: Improved durability, wear resistance, and thermal insulation for aircraft components.

- Medical Industry: Biocompatibility, corrosion resistance, and antibacterial properties for implants and medical devices.

- Energy Industry: Corrosion protection, erosion resistance, and thermal insulation for oil and gas pipelines and equipment.

- Manufacturing Industry: Wear resistance, corrosion protection, and lubrication for cutting tools and machinery.

8. What are the limitations of ceramic coatings?

- Brittleness: Ceramic coatings can be brittle under certain conditions, which may limit their application in high-impact environments.

- Cost: Ceramic coatings can be relatively expensive compared to other types of coatings.

- Substrate Compatibility: Ceramic coatings may not be suitable for all substrate materials, due to factors such as thermal expansion mismatch.

- Process Complexity: Ceramic coating application processes can be complex and require specialized equipment and expertise.

- Repair Challenges: Repairing ceramic coatings can be difficult and may require specific techniques or equipment.

9. How do you handle complex ceramic coating projects that require special expertise?

- Collaboration: Consulting with experts, such as material scientists or engineers, to develop customized solutions.

- Research and Development: Conducting experiments and exploring new coating materials and processes to meet specific project requirements.

- Testing and Validation: Rigorously testing and validating coating performance to ensure it meets the project specifications.

- Equipment Modification: Adapting or modifying coating equipment to accommodate unique project requirements.

- Partnerships: Forming partnerships with specialized coating companies or research institutions to access advanced capabilities.

10. Describe a situation where you successfully resolved a challenging ceramic coating issue.

- Challenge: Poor adhesion of a ceramic coating on a specific substrate material.

- Approach: Investigated the surface characteristics of the substrate, analyzed the coating material, and conducted adhesion tests.

- Solution: Modified the substrate surface preparation process and adjusted the coating composition to improve adhesion.

- Result: Improved coating adhesion and enhanced product performance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Coater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Coater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramic Coaters are accountable for applying ceramic coatings to vehicles. These coatings protect vehicles from environmental elements and preserve their appearance. Key responsibilities include:

1. Ceramic Coating Application

Apply ceramic coatings to vehicles meticulously following established procedures.

- Prepare vehicle surfaces by cleaning, decontaminating, and polishing to ensure optimal coating adhesion.

- Apply ceramic coatings using specialized techniques, ensuring even distribution and proper curing.

2. Vehicle Maintenance and Protection

Preserve the appearance and integrity of vehicles through proper maintenance and protection measures:

- Perform regular inspections to identify any damage or wear.

- Recommend and apply protective treatments, such as waxes and sealants, to maintain the vehicle’s finish.

3. Customer Service and Communication

Ensure customer satisfaction by providing exceptional service and clear communication:

- Explain the benefits and application process of ceramic coatings to customers.

- Maintain open and professional communication throughout the coating process, addressing customer inquiries and concerns.

4. Quality Control and Inspection

Maintain high standards by adhering to quality control measures and conducting thorough inspections:

- Inspect coated vehicles to ensure proper application and adherence to specifications.

- Identify and resolve any issues promptly to ensure customer satisfaction.

Interview Tips

To ace the interview for a Ceramic Coater position, meticulous preparation is crucial. Here are some tips to help you stand out:

1. Research the Company and Industry

Familiarize yourself with the company’s background, values, and the ceramic coating industry. Researching industry trends and best practices will demonstrate your enthusiasm and knowledge.

- Visit the company website and social media pages to learn about their culture and recent developments.

- Read industry publications and articles to stay up-to-date on the latest techniques and technologies.

2. Practice Your Communication Skills

Ceramic Coaters are expected to communicate effectively with customers. Prepare to discuss your experience in customer service and communication:

- Prepare examples of how you handled challenging customer interactions, demonstrating your empathy and problem-solving abilities.

- Practice explaining the benefits and application process of ceramic coatings in a clear and concise manner.

3. Highlight Your Attention to Detail

Ceramic coating application requires meticulous attention to detail. Emphasize your ability to work precisely and follow instructions carefully:

- Describe experiences where you demonstrated precision and accuracy in completing tasks.

- Explain how you maintain a clean and organized work area, ensuring the highest quality of work.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position. Prepare questions relevant to the company, the role, and the industry:

- Inquire about the company’s commitment to using eco-friendly and innovative coating products.

- Ask about opportunities for professional development and training programs specific to ceramic coating.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramic Coater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.