Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ceramic Designer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

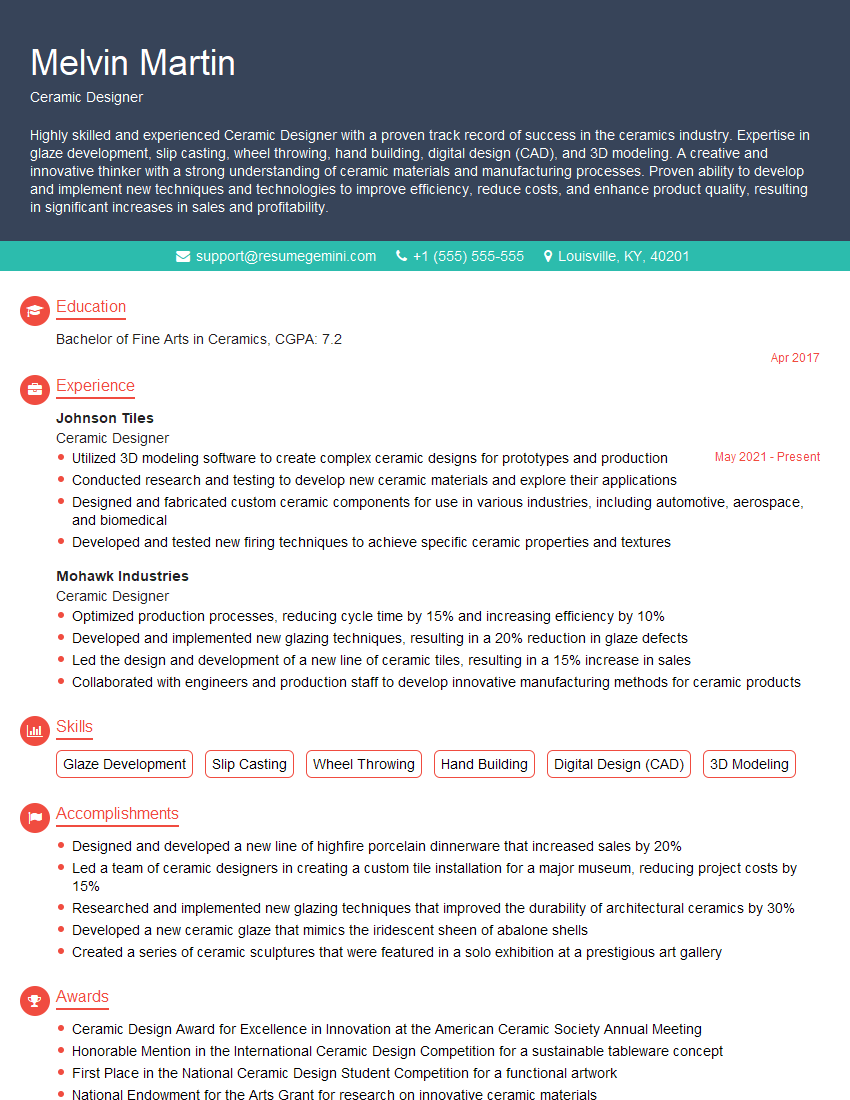

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Designer

1. Explain the process of creating a ceramic design from conception to production?

- Concept Development: Ideation, research, sketching, and mood boarding.

- Prototyping: Creating physical models to test design, functionality, and aesthetics.

- Material Selection: Determining the type of clay, glazes, and other materials to use.

- Production Planning: Outlining the steps, timelines, and resources required for production.

- Manufacturing: Shaping, glazing, and firing the ceramic pieces.

- Quality Control: Ensuring the pieces meet design and quality standards.

2. What are the key factors to consider when designing a ceramic product for a specific market?

- Target Audience: Understanding the demographics, preferences, and needs of the intended consumers.

- Market Trends: Analyzing current and emerging trends in the ceramic industry.

- Functionality: Designing the product to meet the intended purpose and address user needs.

- Aesthetics: Creating a visually appealing design that aligns with market preferences and design principles.

- Pricing: Ensuring the product is priced competitively and aligns with the perceived value.

- Sustainability: Considering the environmental impact of materials, production processes, and packaging.

3. How do you stay updated with the latest trends and innovations in ceramic design?

- Attending Industry Events: Visiting trade shows, conferences, and workshops to connect with experts and learn about new technologies.

- Reading Industry Publications: Subscribing to magazines, online journals, and newsletters focused on ceramics.

- Exploring Online Resources: Utilizing social media, websites, and online communities to stay informed about design trends and best practices.

- Networking with Ceramicists: Connecting with fellow designers, artists, and craftspeople to exchange ideas and gain insights.

- Experimenting with New Techniques: Continuously exploring new materials, glazing methods, and firing techniques to expand creative horizons.

4. Describe your approach to creating unique and original ceramic designs?

- Inspiration: Drawing inspiration from various sources, such as nature, art, culture, and personal experiences.

- Sketching and Ideation: Developing multiple design concepts through sketching, brainstorming, and experimenting with different forms and textures.

- Material Exploration: Experimenting with different clays, glazes, and other materials to create unique textures, colors, and effects.

- Prototyping and Refinement: Creating physical models to evaluate designs, test functionality, and refine details.

- Storytelling: Incorporating narratives and personal experiences into designs to create emotional connections with users.

5. Provide examples of your experience using different ceramic glazes and techniques?

- Glaze Development: Formulating and testing custom glazes to achieve specific colors, textures, and finishes.

- Glaze Application: Mastering various techniques, such as dipping, pouring, spraying, and brushwork, to apply glazes evenly and create desired effects.

- Multiple Glazing: Combining multiple glazes to create layered, complex, and visually stunning surfaces.

- Special Effects: Utilizing techniques like underglazing, slip trailing, and sgraffito to add decorative elements and enhance the visual appeal of ceramics.

- Kiln Firing: Understanding the principles of kiln firing, controlling temperature and atmosphere to achieve desired results.

6. How do you ensure the quality and consistency of ceramic products during production?

- Establishing Quality Standards: Defining clear specifications and parameters for product dimensions, color, texture, and functionality.

- Raw Material Control: Ensuring the consistency and quality of raw materials, including clay, glazes, and other ingredients.

- Process Monitoring: Monitoring production processes, such as shaping, glazing, and firing, to identify and correct any deviations.

- Quality Assurance Testing: Conducting regular testing to assess the strength, durability, and aesthetic qualities of products.

- Continuous Improvement: Regularly reviewing and improving production processes to enhance efficiency and ensure consistency.

7. Can you explain the different types of kilns used in ceramic production and their advantages and disadvantages?

- Advantages: Precise temperature control, energy efficiency, no fumes or emissions.

- Disadvantages: Limited size, higher initial cost.

- Advantages: High temperatures, even firing, lower operating costs.

- Disadvantages: Flue gases, potential for fire or explosion hazards, less precise temperature control.

- Advantages: Unique aesthetic effects, reduced carbon footprint.

- Disadvantages: Difficult to control temperature, high fuel consumption, environmental impact.

Electric Kilns:

Gas Kilns:

Wood Kilns:

8. How do you approach the design of ceramic products in terms of sustainability?

- Material Selection: Using sustainable materials, such as recycled clays, organic pigments, and reclaimed glazes.

- Energy-Efficient Production: Optimizing kiln firing cycles, utilizing energy-saving technologies, and reducing waste.

- Waste Reduction: Minimizing waste through recycling, repurposing, and using alternative materials.

- Lifecycle Assessment: Considering the environmental impact of products throughout their entire lifecycle, including disposal and recycling.

- Education and Awareness: Raising awareness about sustainable practices in ceramic design among clients, manufacturers, and the public.

9. What software programs do you use for ceramic design and how do they enhance your workflow?

- 3D Modeling Software: Using software like Blender or Rhino to create virtual models of ceramic designs, allowing for rapid prototyping and visualization.

- Glaze Calculation Software: Utilizing programs to calculate glaze recipes, optimize color outcomes, and reduce trial and error.

- Pattern Design Software: Employing software like Adobe Illustrator or Photoshop to create intricate patterns and designs for ceramics.

- Project Management Software: Using tools like Trello or Asana to organize projects, track progress, and collaborate with team members.

10. How do you handle client feedback and incorporate it into your design process?

- Active Listening: Carefully listening to client feedback, understanding their needs, and asking clarifying questions.

- Analysis and Evaluation: Analyzing feedback to identify common themes, areas for improvement, and potential design opportunities.

- Iteration and Refinement: Modifying designs based on feedback, presenting revised concepts, and working iteratively until client satisfaction is achieved.

- Communication and Transparency: Keeping clients informed throughout the design process, explaining decisions, and ensuring alignment on outcomes.

- Collaboration and Perspective: Viewing client feedback as a collaborative opportunity, seeking different perspectives and working together to achieve the best possible results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramic Designers are responsible for creating and developing new ceramic products. They work with various materials, including clay, porcelain, and stoneware, to produce functional and decorative items. Their key responsibilities include:

1. Concept Development

Creating innovative design concepts for new ceramic products based on market research.

- Sketching and rendering design ideas

- Developing prototypes and testing different materials

2. Product Design

Designing and developing new ceramic products according to specifications and customer requirements.

- Determining appropriate materials and manufacturing processes

- Creating technical drawings and specifications

3. Production Monitoring

Monitoring the production process to ensure product quality and consistency.

- Inspecting raw materials and finished products

- Working with production team to resolve any issues

4. Customer Service

Providing technical support and advice to customers regarding ceramic products and their applications.

- Answering customer inquiries and resolving complaints

- Providing training and demonstrations on product usage

Interview Tips

To ace an interview for a Ceramic Designer position, consider the following preparation tips:

1. Research the Company and Position

Thoroughly research the company and the specific job requirements to gain a deep understanding of the organization.

- Visit the company website and read about their mission, values, and products.

- Review the job description carefully and identify the key skills and experience required.

2. Highlight Your Design Skills

Showcase your portfolio and emphasize your design capabilities relevant to the role.

- Bring a physical or digital portfolio that demonstrates your creativity, technical skills, and problem-solving abilities.

- Discuss your design process and how you translate concepts into tangible products.

3. Demonstrate Your Knowledge of Ceramics

Display your expertise in ceramic materials, manufacturing techniques, and industry trends.

- Discuss your knowledge of different types of clay, glazes, and firing processes.

- Demonstrate understanding of ceramic design principles and industry standards.

4. Emphasize Your Problem-Solving Skills

Highlight your ability to identify and solve problems related to ceramic design and production.

- Provide examples of how you have overcome technical challenges in previous projects.

- Explain your approach to optimizing designs, reducing costs, and ensuring product quality.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ceramic Designer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ceramic Designer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.