Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ceramic Engineering Professor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

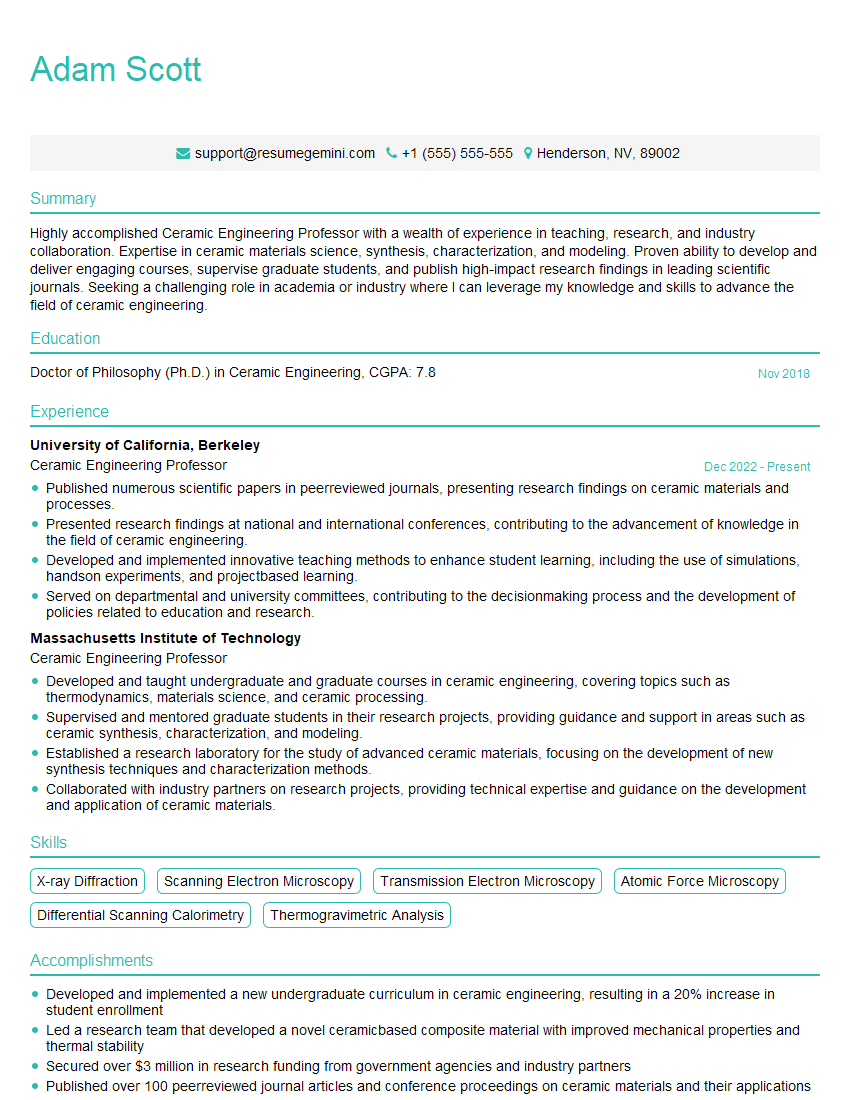

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Engineering Professor

1. How would you describe the relationship between the microstructure and properties of ceramics?

- The microstructure of a ceramic material, which refers to the arrangement of its constituent phases, plays a crucial role in determining its properties.

- The size, shape, and distribution of grains, pores, and other microstructural features can significantly affect properties such as strength, toughness, electrical conductivity, and optical transparency.

- For example, a ceramic with a fine-grained microstructure tends to be stronger and tougher than one with a coarse-grained microstructure.

- Understanding the microstructure-property relationship is essential for designing and optimizing ceramic materials for specific applications.

2. What are the key factors that influence the sintering behavior of ceramics?

Thermodynamic factors

- The driving force for sintering is the reduction of surface energy.

- The presence of impurities or second phases can inhibit sintering by forming barriers to grain growth.

Kinetic factors

- The rate of sintering is controlled by the diffusion of atoms and ions through the grain boundaries.

- The temperature and duration of the sintering process affect the kinetics of sintering.

Microstructural factors

- The initial particle size and distribution can influence the final microstructure and properties of the sintered ceramic.

- The presence of porosity can also affect the sintering behavior.

3. How would you approach the design of a ceramic material for a specific application?

- First, I would identify the key properties required for the application, such as strength, toughness, electrical conductivity, or optical transparency.

- Next, I would research the different types of ceramics and their properties to determine which type is best suited for the application.

- I would then consider the processing techniques that can be used to achieve the desired microstructure and properties.

- Finally, I would optimize the processing parameters to achieve the desired outcome.

4. What are the advantages and disadvantages of using sol-gel processing to fabricate ceramic materials?

Advantages

- Sol-gel processing allows for the production of ceramics with high purity and homogeneity.

- The process is relatively simple and can be used to produce a wide variety of ceramic materials.

- Sol-gel derived ceramics often have unique properties, such as high porosity and surface area.

Disadvantages

- Sol-gel processing can be time-consuming and expensive.

- The process can be sensitive to variations in processing parameters.

- The final properties of the ceramic material can be affected by the aging and drying conditions.

5. How would you characterize the surface properties of a ceramic material?

- The surface properties of a ceramic material can be characterized using a variety of techniques, including:

- Scanning electron microscopy (SEM)

- Atomic force microscopy (AFM)

- X-ray diffraction (XRD)

- Contact angle measurements

- These techniques can be used to determine the surface morphology, roughness, crystallinity, and wettability of the ceramic material.

6. What are the different types of defects that can occur in ceramic materials?

- Point defects:

- Vacancies, interstitials, and substitutional impurities

- Line defects:

- Dislocations and grain boundaries

- Surface defects:

- Cracks, pores, and scratches

- Volume defects:

- Inclusions and precipitates

7. How would you measure the thermal conductivity of a ceramic material?

- The thermal conductivity of a ceramic material can be measured using a variety of techniques, including:

- The steady-state method

- The transient method

- The laser flash method

- These techniques involve measuring the temperature gradient across a sample of the ceramic material under controlled conditions.

8. What are the different types of ceramic sensors?

- Ceramic sensors can be classified into two main types:

- Passive sensors

- Active sensors

- Passive sensors respond to changes in their environment by changing their electrical properties.

- Active sensors generate an electrical signal that is proportional to the change in their environment.

9. How would you design a ceramic material for use in a high-temperature application?

- To design a ceramic material for use in a high-temperature application, I would consider the following factors:

- The operating temperature

- The mechanical loads that the material will be subjected to

- The chemical environment

- I would then select a ceramic material that has the appropriate properties to meet the requirements of the application.

10. What are the current research trends in ceramic engineering?

- Some of the current research trends in ceramic engineering include:

- The development of new ceramic materials with improved properties

- The use of ceramic materials in new applications

- The development of new processing techniques for ceramic materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Engineering Professor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Engineering Professor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramic Engineering Professors are responsible for educating and training students in the field of ceramic engineering. They conduct research and publish papers in academic journals, and they also serve as consultants to industry.

1. Teaching

Teaching is a primary responsibility of ceramic engineering professors. They develop and deliver lectures, lead discussions, and grade assignments. They also advise students on their academic and career goals.

2. Research

Research is another important responsibility of ceramic engineering professors. They conduct research in a variety of areas, such as the development of new ceramic materials, the improvement of ceramic processing techniques, and the application of ceramics in various industries.

3. Service

Ceramic engineering professors also provide service to their profession and to the community. They serve on committees, give presentations at conferences, and review papers for academic journals. They also work with industry to develop new products and processes.

4. Other Responsibilities

In addition to teaching, research, and service, ceramic engineering professors may also have other responsibilities, such as:

- Advising students

- Developing new courses

- Writing grant proposals

- Serving on departmental committees

Interview Tips

Preparing for an interview for a ceramic engineering professor position can be a daunting task. However, by following these tips, you can increase your chances of success.

1. Research the Position and the Institution

Before you go on an interview, it is important to research the position and the institution. This will help you to understand the expectations of the job and to tailor your answers to the interviewer’s questions.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and concisely. Some common interview questions include:

- Tell me about your research experience.

- What are your teaching interests?

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your career goals?

3. Bring Your Portfolio

If you have a portfolio of your work, be sure to bring it with you to the interview. This will give the interviewer a chance to see the quality of your work and to assess your skills.

4. Be Yourself

It is important to be yourself during the interview. The interviewer will be able to tell if you are being genuine, and they will be more likely to hire you if they feel like they can get to know the real you.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramic Engineering Professor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!