Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ceramic Research Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

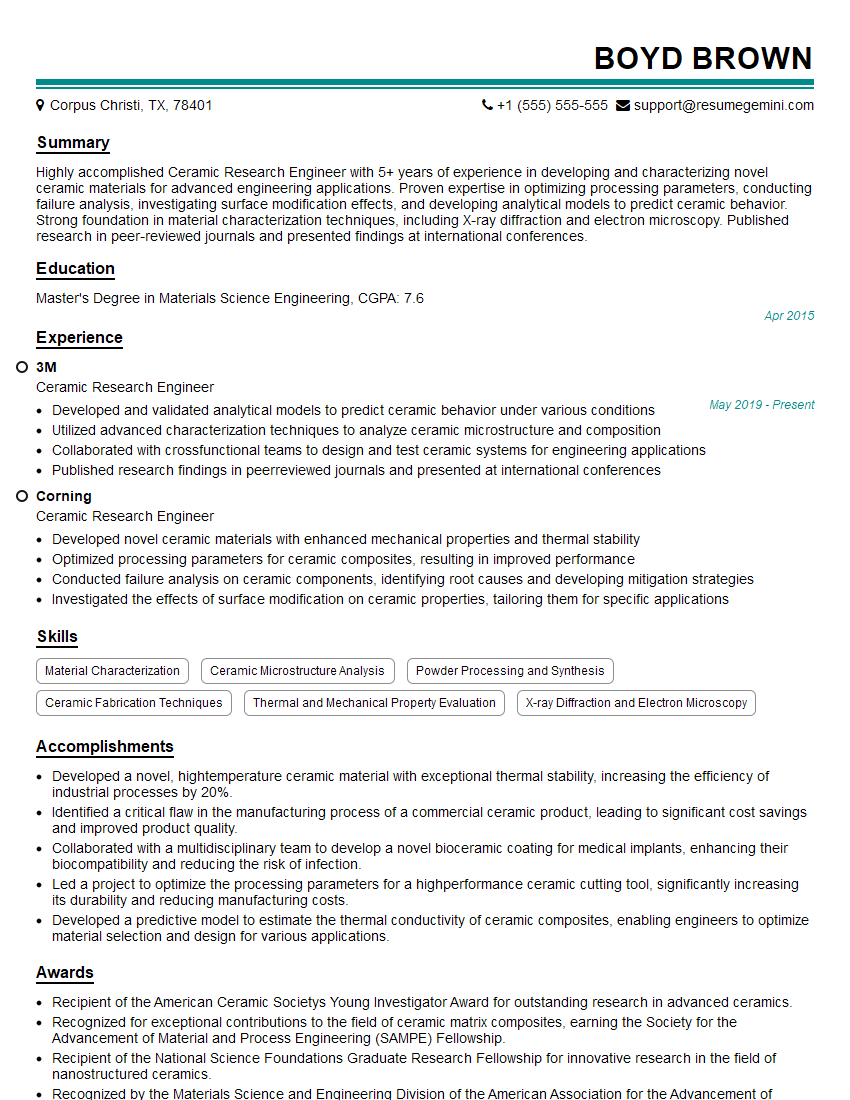

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramic Research Engineer

1. What are the different types of ceramic materials and their applications?

- Traditional ceramics: These are the most common type of ceramics and are made from clay, feldspar, and silica. They are used in a wide variety of applications, including tiles, pottery, and bricks.

- Advanced ceramics: These are a newer type of ceramic that is made from more exotic materials, such as zirconia, alumina, and silicon carbide. They are used in a variety of high-performance applications, such as cutting tools, bearings, and armor.

- Glass-ceramics: These are a type of ceramic that is made from a mixture of glass and ceramic materials. They are used in a variety of applications, such as cookware, windshields, and optical fibers.

2. What are the key properties of ceramic materials?

Mechanical properties

- Strength

- Hardness

- Toughness

Thermal properties

- Melting point

- Thermal conductivity

- Specific heat capacity

Electrical properties

- Electrical conductivity

- Dielectric constant

- Piezoelectric properties

Optical properties

- Refractive index

- Transparency

- Color

3. What are the different methods for processing ceramic materials?

- Powder processing: This method involves mixing ceramic powders with water or other solvents to form a slurry. The slurry is then shaped into the desired form and dried.

- Slip casting: This method involves pouring a ceramic slip (a mixture of ceramic powders and water) into a mold. The slip sets up in the mold and forms a solid object.

- Extrusion: This method involves forcing a ceramic paste through a die to form a continuous shape.

- Pressing: This method involves pressing a ceramic powder into a die to form a desired shape.

- Sintering: This method involves heating a ceramic body to a high temperature to bond the particles together.

4. What are the different types of ceramic glazes?

- Clear glazes: These glazes are transparent and allow the color of the ceramic body to show through.

- Opaque glazes: These glazes are not transparent and hide the color of the ceramic body.

- Matt glazes: These glazes have a dull, non-glossy finish.

- Glossy glazes: These glazes have a shiny, glossy finish.

- Crystalline glazes: These glazes contain crystals that form during the firing process.

5. What are the different types of ceramic kilns?

- Electric kilns: These kilns use electricity to heat the ceramic body.

- Gas kilns: These kilns use gas to heat the ceramic body.

- Wood-fired kilns: These kilns use wood to heat the ceramic body.

- Salt kilns: These kilns use salt to create a reducing atmosphere that gives the ceramic body a unique color and texture.

- Soda kilns: These kilns use soda to create a fluxing atmosphere that melts the glaze and gives the ceramic body a glossy finish.

6. What are the different types of ceramic defects?

- Cracks: These are breaks in the ceramic body that can be caused by a variety of factors, such as thermal stress, mechanical stress, or chemical attack.

- Chips: These are small pieces of the ceramic body that have been broken off. They can be caused by a variety of factors, such as impact, abrasion, or thermal stress.

- Pinholes: These are small holes in the ceramic body that can be caused by a variety of factors, such as gas bubbles, impurities, or defects in the glaze.

- Glaze defects: These are defects in the glaze that can be caused by a variety of factors, such as improper firing, contamination, or chemical attack.

7. What are the different types of ceramic testing methods?

- Mechanical testing: This type of testing involves measuring the mechanical properties of a ceramic material, such as strength, hardness, and toughness.

- Thermal testing: This type of testing involves measuring the thermal properties of a ceramic material, such as melting point, thermal conductivity, and specific heat capacity.

- Electrical testing: This type of testing involves measuring the electrical properties of a ceramic material, such as electrical conductivity, dielectric constant, and piezoelectric properties.

- Optical testing: This type of testing involves measuring the optical properties of a ceramic material, such as refractive index, transparency, and color.

8. What are the latest trends in ceramic research?

- Development of new ceramic materials with improved properties

- Development of new methods for processing ceramic materials

- Development of new applications for ceramic materials

- Development of new testing methods for ceramic materials

9. What are the challenges facing the ceramic industry?

- Increasing competition from other materials

- Rising costs of raw materials

- Environmental regulations

- Need for new and innovative products

10. What are your strengths and weaknesses as a Ceramic Research Engineer?

- Strengths:

- Strong understanding of ceramic materials and their properties

- Experience in developing and testing new ceramic materials

- Ability to work independently and as part of a team

- Excellent communication and presentation skills

- Weaknesses:

- Limited experience in some areas of ceramic research

- Need to improve time management skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramic Research Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramic Research Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramic Research Engineers are responsible for developing and improving ceramic materials and products. They work in a variety of industries, including aerospace, automotive, biomedical, and electronics. Some of the key job responsibilities of a Ceramic Research Engineer include:

1. Conduct research on ceramic materials

This involves studying the properties of ceramic materials, such as their strength, hardness, and thermal conductivity. Ceramic Research Engineers also investigate new ways to process and manufacture ceramics.

- Design and conduct experiments to test the properties of ceramic materials

- Analyze data and interpret results to identify trends and patterns

2. Develop new ceramic materials and products

Ceramic Research Engineers use their knowledge of ceramic materials to develop new products and applications. This can involve creating new types of ceramics, as well as improving the properties of existing ceramics.

- Identify and develop new markets for ceramic products

- Work with customers to develop custom ceramic solutions

3. Solve technical problems related to ceramics

Ceramic Research Engineers are often called upon to solve technical problems related to ceramics. This can involve troubleshooting problems with ceramic products, as well as developing new solutions to meet customer needs.

- Troubleshoot problems with ceramic products and processes

- Develop and implement new solutions to improve ceramic performance

4. Manage research projects

Ceramic Research Engineers often manage research projects, which can involve overseeing a team of researchers and ensuring that the project is completed on time and within budget.

- Plan and manage research projects from start to finish

- Supervise and mentor a team of researchers

Interview Preparation Tips

Preparing for an interview is essential to increasing your chances of success. Here are a few tips that can help you ace your interview for a Ceramic Research Engineer position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, LinkedIn, and Glassdoor.

- Visit the company website to learn about their products, services, and culture.

- Read the job description carefully and make a list of the key qualifications.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is a good idea to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions about your experience.

- Be prepared to talk about your skills and qualifications, and how they relate to the job requirements.

3. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

4. Follow up after the interview

After the interview, it is important to follow up with the interviewer. This can be done by sending a thank-you note or email. In your follow-up message, you can reiterate your interest in the position and thank the interviewer for their time.

- Send a thank-you note or email within 24 hours of the interview.

- Reiterate your interest in the position and thank the interviewer for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramic Research Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!