Are you gearing up for an interview for a Ceramist position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ceramist and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

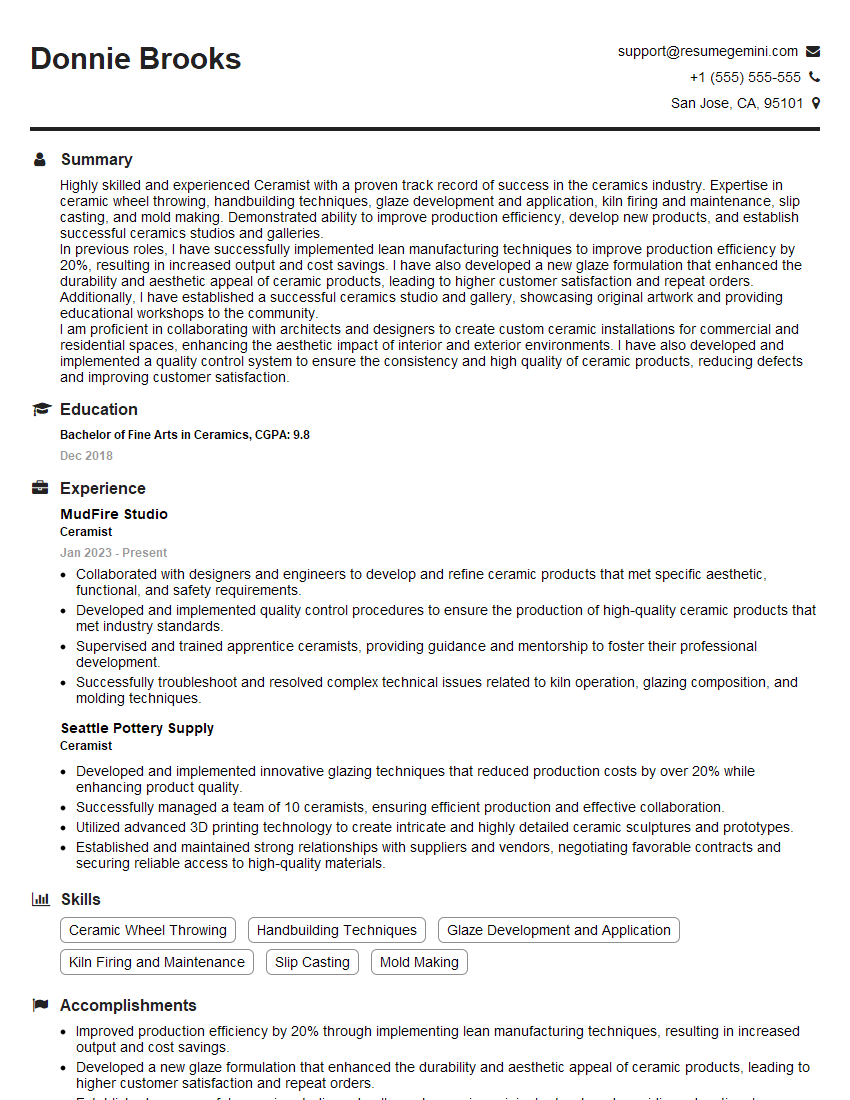

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ceramist

1. Describe the different types of clay bodies you have worked with and their firing properties.

– Earthenware: Fires at a lower temperature (1000-1200°C) and is more porous and absorbs water. – Stoneware: Fires at a higher temperature (1200-1300°C) and is denser, stronger, and less porous. – Porcelain: Fires at the highest temperature (1300-1400°C) and is very strong, hard, and non-porous.

2. What are the different methods of ceramic glazing and what are the advantages and disadvantages of each?

Lead-based glazes

- Advantages: lower firing temperature, brighter colors, more durable

- Disadvantages: toxic, not food safe

Lead-free glazes

- Advantages: food safe, more environmentally friendly

- Disadvantages: higher firing temperature, less durable, more limited color range

3. What are the different types of ceramic kilns and what are their firing capabilities?

- Electric kilns: Most common type, fires using electricity, more precise temperature control

- Gas kilns: Fires using gas, hotter temperatures, more difficult to control temperature

- Wood-fired kilns: Fires using wood, unique atmospheric effects, difficult to control temperature

4. What is the difference between bisque firing and glaze firing?

– Bisque firing: First firing of a ceramic piece to harden it before glazing. – Glaze firing: Second firing of a ceramic piece to melt the glaze and create the desired surface finish.

5. What are the different types of ceramic glazes and what are their properties?

- Clear glazes: Transparent, allow the color of the clay body to show through

- Opaque glazes: Non-transparent, hide the color of the clay body, wider range of colors

- Gloss glazes: Shiny, reflective surface

- Matte glazes: Dull, non-reflective surface

6. What are the different types of ceramic decoration techniques and what are their effects?

- Underglaze decoration: Applied before glazing, colors appear more vibrant

- Overglaze decoration: Applied after glazing, colors are less intense

- Sgraffito: Carving into the clay body to reveal the underlying layers

- Slip trailing: Applying a liquid clay slip to the surface of the piece

7. What are the different types of ceramic kilns and what are their advantages and disadvantages?

- Electric kilns: More precise temperature control, more expensive

- Gas kilns: More difficult to control temperature, less expensive

- Wood-fired kilns: Unique firing effects, difficult to control temperature

8. What are the different types of ceramic firing atmospheres and what are their effects on the finished product?

- Oxidizing atmosphere: Plenty of oxygen available, results in bright colors

- Reducing atmosphere: Limited oxygen available, results in darker colors, metallic effects

9. What are the different types of ceramic glazes and what are their properties?

- Clear glazes: Transparent, allow the color of the clay body to show through

- Opaque glazes: Non-transparent, hide the color of the clay body, wider range of colors

- Gloss glazes: Shiny, reflective surface

- Matte glazes: Dull, non-reflective surface

10. What are the different types of ceramic forming techniques and what are their advantages and disadvantages?

- Wheel throwing: Using a potter’s wheel to form clay, allows for precise control

- Hand building: Forming clay by hand, more organic and expressive

- Slip casting: Pouring liquid clay into a plaster mold, allows for mass production

- Extrusion: Pushing clay through a die to create uniform shapes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ceramist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ceramist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ceramists are responsible for the creation and maintenance of ceramic products, from the initial design to the final firing and glazing. They work with a variety of materials, including clay, glazes, and pigments, to create both functional and decorative objects.

1. Design and Development

Ceramists begin by designing and developing new products. They work closely with customers to determine the specific needs and requirements for each project.

- Sketching and modeling to create new designs

- Working with customers to develop specifications for new products

2. Production and Fabrication

Once a design has been finalized, ceramists begin the production process. They use a variety of techniques to create ceramic objects, including hand-building, wheel-throwing, and casting.

- Mixing and preparing clay and other materials

- Forming and shaping clay into desired shapes

- Applying glazes and other surface treatments

3. Firing and Glazing

After the ceramic objects have been formed, they are fired in a kiln to harden them and make them durable. Ceramists then apply glazes and other surface treatments to create the desired finish.

- Loading and unloading kilns

- Monitoring the firing process to ensure proper temperature and timing

- Applying glazes and other surface treatments to create desired effects

4. Quality Control and Inspection

Ceramists are responsible for ensuring that the finished products meet the required standards of quality. They inspect each piece for defects and make any necessary corrections.

- Inspecting finished products for defects

- Making repairs and adjustments as needed

- Maintaining quality control records

Interview Tips

Preparing for a ceramist interview requires a combination of technical knowledge, artistic ability, and communication skills. Here are some tips to help you ace your interview:

1. Research the Company and the Role

Before the interview, it’s essential to thoroughly research the company and the specific role you’re applying for. This will help you understand the company’s culture, values, and specific needs for the position.

- Visit the company’s website to learn about their history, products, and services

- Read industry publications and articles to stay updated on current trends and technologies

- Connect with current or former employees on LinkedIn to gain insights into the company culture

2. Practice Your Technical Skills

As a ceramist, it’s crucial to have a strong foundation in technical skills. Be prepared to discuss your experience with different types of clay, glazes, and firing techniques.

- Create a portfolio of your work to showcase your skills and creativity

- Prepare to answer questions about your knowledge of ceramic materials and processes

- Consider taking a refresher course or workshop to enhance your technical abilities

3. Highlight Your Artistic Ability

Ceramics is an art form, so it’s important to be able to demonstrate your artistic ability during the interview. Discuss your inspiration, creative process, and unique approach to design.

- Bring examples of your work to the interview to showcase your artistic vision

- Be prepared to talk about your influences and how they shape your work

- Discuss your experience with different artistic techniques and mediums

4. Emphasize Your Communication Skills

Ceramists often work with clients, colleagues, and vendors. Strong communication skills are essential for discussing design ideas, resolving issues, and building relationships.

- Be prepared to answer questions about your ability to work effectively in a team environment

- Provide examples of your experience communicating complex technical information to non-experts

- Practice your active listening skills and ability to ask clarifying questions

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the role. It also gives you an opportunity to learn more about the company and the position.

- Prepare questions about the company’s growth plans, industry trends, or specific projects

- Ask about the company’s commitment to sustainability or social responsibility

- Inquire about the opportunities for professional development and advancement within the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ceramist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!