Feeling lost in a sea of interview questions? Landed that dream interview for Cereal Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cereal Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

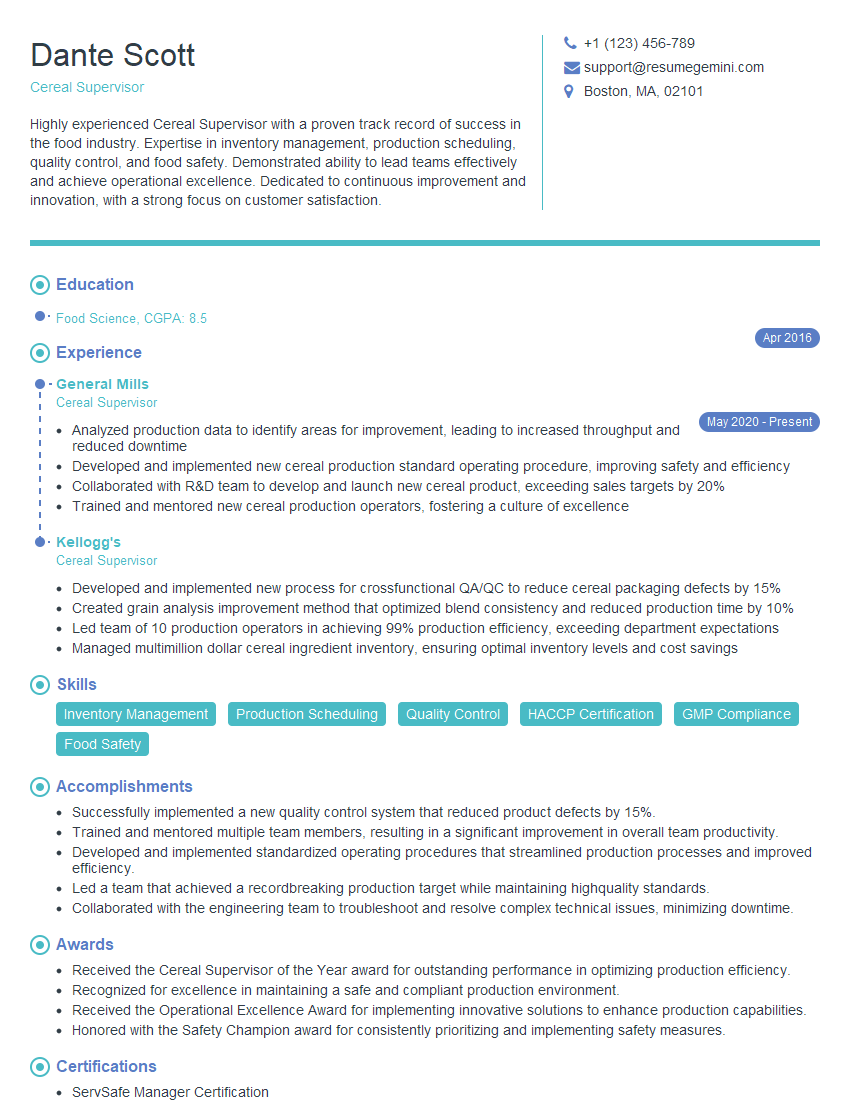

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cereal Supervisor

1. Describe the key performance indicators (KPIs) you use to measure the effectiveness of your cereal production process?

To measure the effectiveness of my cereal production process, I track a range of KPIs, including:

- Production output: This measures the total volume of cereal produced during a specific period.

- Production efficiency: This measures the amount of cereal produced per unit of input, such as raw materials and labour.

- Product quality: This measures the adherence of the cereal to established quality standards and customer specifications.

- Customer satisfaction: This measures the level of customer satisfaction with the cereal products and services provided.

- Cost of production: This measures the total cost of producing a unit of cereal, including raw materials, labour, and overhead expenses.

2. Explain how you ensure that the cereal production process meets food safety and quality standards?

HACCP implementation

- Implement and maintain a Hazard Analysis Critical Control Point (HACCP) system to identify and control potential food safety hazards throughout the production process.

- Establish critical control points and monitor them regularly to ensure compliance with food safety regulations and standards.

Quality control measures

- Conduct regular product testing and inspections to ensure that the cereal meets established quality specifications.

- Implement quality control procedures to minimize the risk of contamination and ensure the safety and wholesomeness of the cereal products.

3. Describe your approach to managing inventory levels for cereal raw materials and finished products?

To effectively manage inventory levels, I follow a systematic approach:

- Demand forecasting: Utilize historical data and market analysis to predict future demand for both raw materials and finished products.

- Safety stock maintenance: Maintain appropriate safety stock levels to buffer against unexpected fluctuations in demand or supply.

- Inventory optimization: Implement inventory optimization techniques, such as just-in-time (JIT) inventory management, to minimize inventory holding costs and maximize efficiency.

- Supplier relationship management: Establish strong relationships with suppliers to ensure reliable and timely delivery of raw materials.

- Inventory control system: Utilize an inventory control system to track stock levels, monitor usage, and generate reorder points.

4. How do you handle production scheduling and capacity planning for the cereal production process?

To optimize production scheduling and capacity planning, I employ the following strategies:

- Production planning: Develop production plans based on demand forecasts and inventory levels to ensure efficient utilization of resources.

- Capacity analysis: Conduct regular capacity analysis to assess the production capacity of the facility and identify potential bottlenecks.

- Scheduling optimization: Utilize scheduling optimization techniques, such as Gantt charts or production scheduling software, to allocate resources and minimize production delays.

- Contingency planning: Establish contingency plans to address unexpected events or disruptions that may affect production schedules.

5. Describe your experience with implementing and managing quality control systems in a cereal production facility?

In my previous role, I was responsible for implementing and managing a comprehensive quality control system in a cereal production facility. Key aspects of my approach included:

- Establishing quality standards: Developed and implemented quality standards for raw materials, finished products, and production processes.

- Inspection and testing: Conducted regular inspections and testing of raw materials, in-process products, and finished goods to ensure compliance with quality standards.

- Corrective and preventive actions: Implemented corrective and preventive action procedures to address quality deviations and prevent their recurrence.

- Continuous improvement: Regularly reviewed and updated the quality control system to enhance its effectiveness and efficiency.

6. How do you ensure the efficient and cost-effective operation of cereal production equipment?

To ensure the efficient and cost-effective operation of cereal production equipment, I focus on the following practices:

- Preventive maintenance: Implement a preventive maintenance program to regularly inspect and service equipment to prevent breakdowns and minimize downtime.

- Operator training: Provide comprehensive training to operators on equipment operation and maintenance procedures to enhance proficiency and reduce errors.

- Performance monitoring: Monitor equipment performance through sensors and data analysis to identify areas for improvement and optimize efficiency.

- Energy efficiency: Evaluate energy consumption and implement energy efficiency measures, such as variable frequency drives and energy-saving lighting, to reduce operating costs.

7. Describe your approach to waste management and sustainability in cereal production?

To promote sustainability and minimize waste in cereal production, I employ the following strategies:

- Waste reduction: Implement waste reduction initiatives, such as reducing packaging waste and optimizing production processes to minimize by-products.

- Recycling and composting: Establish recycling programs for materials such as cardboard, plastic, and metal. Explore composting options for organic waste, such as cereal by-products.

- Energy conservation: Implement energy conservation measures throughout the facility, such as energy-efficient lighting and equipment, to reduce the environmental footprint.

- Supplier engagement: Collaborate with suppliers to promote sustainable practices and reduce the environmental impact of raw materials.

8. How do you manage a team of production operators in a cereal production facility?

To effectively manage a team of production operators in a cereal production facility, I adopt the following strategies:

- Clear communication: Establish clear communication channels and ensure that all team members are informed about goals, expectations, and procedures.

- Delegation and empowerment: Delegate tasks and responsibilities to team members to empower them and foster a sense of ownership.

- Performance management: Regularly assess and provide feedback on team members’ performance to identify areas for improvement and recognition.

- Teamwork and collaboration: Promote teamwork and collaboration among team members to encourage knowledge sharing and problem-solving.

- Training and development: Invest in training and development opportunities for team members to enhance their skills and knowledge.

9. Describe your experience with implementing new technologies in a cereal production facility?

In my previous role, I was involved in implementing several new technologies in a cereal production facility, including:

- Automated packaging line: Implemented an automated packaging line to improve packaging efficiency, reduce labour costs, and enhance product quality.

- Sensors and data analytics: Installed sensors and implemented data analytics to monitor equipment performance, identify potential issues, and optimize production processes.

- Predictive maintenance software: Utilized predictive maintenance software to analyze equipment data and predict maintenance needs, reducing downtime and improving equipment reliability.

10. How do you stay updated on the latest trends and best practices in cereal production?

To stay updated on the latest trends and best practices in cereal production, I engage in the following activities:

- Industry conferences and events: Attend industry conferences and events to network with peers, learn about new technologies, and gain insights into best practices.

- Technical publications and journals: Subscribe to technical publications and journals to stay informed about advancements in cereal production methods, equipment, and quality control.

- Online research and webinars: Conduct online research and participate in webinars to access the latest information and knowledge resources.

- Collaboration with experts: Collaborate with industry experts, consultants, and researchers to gain insights into emerging trends and innovative approaches.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cereal Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cereal Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cereal Supervisors are responsible for overseeing the production of cereals in a manufacturing plant. They ensure that the cereals meet quality standards and are produced efficiently.

1. Manage Production

Cereal Supervisors oversee the production process from start to finish. They ensure that the cereals are produced according to specifications and that the equipment is operating properly.

- Plan and schedule production runs

- Coordinate with other departments to ensure that materials and equipment are available

- Monitor production lines and make adjustments as needed

- Ensure that products meet quality standards

2. Supervise Staff

Cereal Supervisors supervise a team of production workers. They train and motivate employees and ensure that they are following safety procedures.

- Hire, train, and supervise production workers

- Set performance goals and provide feedback

- Resolve employee conflicts

- Ensure that employees are following safety procedures

3. Maintain Equipment

Cereal Supervisors are responsible for maintaining the equipment used in the production process. They perform regular inspections and make repairs as needed.

- Inspect and maintain equipment

- Order replacement parts and supplies

- Troubleshoot and repair equipment problems

- Coordinate with maintenance staff

4. Quality Control

Cereal Supervisors are responsible for ensuring that the cereals produced meet quality standards. They conduct quality checks and take corrective action as needed.

- Conduct quality checks on cereals

- Identify and resolve quality problems

- Implement quality improvement programs

- Train employees on quality standards

Interview Tips

To ace your interview for a Cereal Supervisor position, it is important to be prepared. Here are a few tips to help you prepare:

1. Research the Company

Before your interview, take some time to research the company you are interviewing with. This will help you understand their business, their products, and their culture.

- Visit the company’s website

- Read news articles about the company

- Talk to people who work at the company

2. Practice Your Answers

Once you have a good understanding of the company, you can start practicing your answers to common interview questions. This will help you feel more confident and prepared during your interview.

- Prepare answers to questions about your experience, skills, and qualifications

- Practice answering questions about your strengths and weaknesses

- Prepare questions to ask the interviewer

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothing that is clean, pressed, and fits well

- Avoid wearing clothing that is too revealing or casual

- Make sure your shoes are clean and polished

4. Be Punctual

Punctuality shows that you respect the interviewer’s time. Arrive for your interview on time, or even a few minutes early.

- Plan your route to the interview location in advance

- Leave early to allow for unexpected delays

- If you are running late, call the interviewer to let them know

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Cereal Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Cereal Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.