Are you gearing up for an interview for a Certified Maintenance Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Certified Maintenance Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

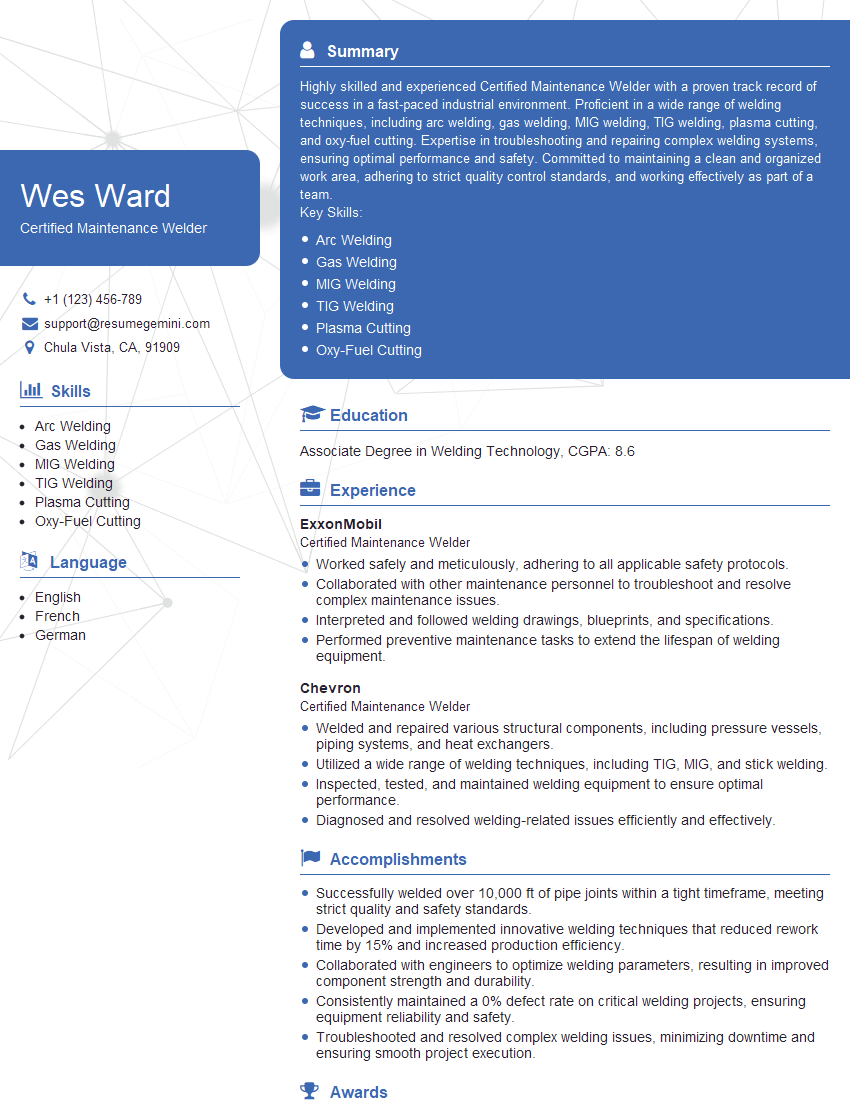

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Certified Maintenance Welder

1. Describe the steps involved in gas metal arc welding (GMAW)?

- Preparing the metal surfaces to be welded by cleaning and removing any rust or debris.

- Selecting the appropriate welding wire and shielding gas.

- Setting the welding machine to the correct voltage and wire feed speed.

- Guiding the welding torch along the joint to be welded, maintaining a consistent distance between the torch and the metal.

- Feeding the welding wire into the weld pool as needed.

- Inspecting the weld after it has cooled to ensure that it is of good quality.

2. What are the different types of welds that can be performed using GMAW?

Butt welds

- Joining two pieces of metal together edge-to-edge.

Edge welds

- Joining two pieces of metal together by overlapping their edges.

T-welds

- Joining two pieces of metal together at a right angle.

Corner welds

- Joining two pieces of metal together at a 90-degree angle.

3. What are the advantages of using GMAW over other welding processes?

- Faster welding speeds.

- Lower heat input, which can reduce distortion and heat-affected zone.

- Better weld quality, with fewer defects.

- Greater versatility, as it can be used to weld a wide variety of metals.

- Easier to learn and use than other welding processes.

4. What are the safety precautions that should be taken when performing GMAW?

- Wear appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing.

- Ensure that the work area is well-ventilated to prevent the inhalation of welding fumes.

- Keep flammable materials away from the welding area.

- Do not touch the welding torch or electrode with bare hands.

- Allow the welding equipment to cool down before handling it.

5. What are some of the common problems that can occur when performing GMAW and how can they be prevented?

- Porosity: Caused by the entrapment of gas bubbles in the weld pool. Can be prevented by using a clean welding gas and ensuring that the metal surfaces are free of moisture and contaminants.

- Lack of fusion: Caused by incomplete melting of the metal surfaces. Can be prevented by increasing the heat input or using a larger diameter welding wire.

- Undercut: Caused by excessive melting of the base metal. Can be prevented by reducing the heat input or using a smaller diameter welding wire.

- Cold lap: Caused by the failure of the weld metal to fuse properly with the base metal. Can be prevented by increasing the heat input or using a larger diameter welding wire.

6. What is the difference between a flux-cored arc welding (FCAW) and a GMAW?

- FCAW uses a tubular welding wire that contains a flux, which produces a protective gas shield around the weld pool.

- GMAW uses a solid welding wire and a separate shielding gas, which is supplied from a cylinder.

7. What are the advantages of using FCAW over GMAW?

- Higher deposition rates.

- Less spatter.

- Better penetration.

- Can be used in outdoor applications.

8. What are the disadvantages of using FCAW over GMAW?

- More difficult to control the weld pool.

- More smoke and fumes are produced.

- Can be more expensive than GMAW.

9. What are some of the applications of GMAW?

- Automotive industry

- Construction

- Shipbuilding

- Aerospace industry

- General fabrication

10. What are some of the applications of FCAW?

- Heavy fabrication

- Shipbuilding

- Offshore construction

- Pipelines

- Bridges

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Certified Maintenance Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Certified Maintenance Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Certified Maintenance Welders play a vital role in ensuring the proper functioning and longevity of equipment and structures across various industries such as manufacturing, construction, and power generation. The key responsibilities of a Certified Maintenance Welder involve:

1. Welding and Repair

Perform welding and repair tasks on a variety of materials, including steel, stainless steel, aluminum, and other metals.

- Repair structural components, machinery, and equipment using welding techniques.

- Follow welding codes and standards to ensure the quality and safety of welded joints.

2. Maintenance and Inspection

Inspect and maintain welding equipment and tools to ensure optimal performance and safety.

- Conduct regular inspections of welded components and structures to identify potential issues.

- Implement preventative maintenance procedures to prolong the lifespan of welding equipment.

3. Planning and Troubleshooting

Analyze and interpret blueprints and welding procedures to determine the appropriate welding techniques and materials.

- Troubleshoot welding problems, identify the cause, and recommend solutions.

- Plan and prepare work areas to ensure a safe and efficient work environment.

4. Quality Control

Ensure the quality and accuracy of welded components through inspections and testing.

- Inspect and test welded joints to verify compliance with specifications and standards.

- Maintain detailed records and documentation of welding activities for traceability and audit purposes.

Interview Tips

Preparing adequately for an interview is essential to showcasing your skills and qualifications. Here are some interview tips and hacks to help you ace your interview for a Certified Maintenance Welder position:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific requirements for the Certified Maintenance Welder role. This demonstrates your interest in the organization and the position.

- Review the company website, LinkedIn profile, and industry news.

- Thoroughly read the job description to understand the key responsibilities and qualifications.

2. Highlight Your Certifications and Experience

Emphasize your welding certifications and relevant experience in your resume and during the interview. Provide specific examples of your welding projects and achievements.

- List your welding certifications (e.g., AWS, ASME, ISO) and indicate the expiration dates.

- Quantify your experience with specific metrics, such as the number of welded joints completed or the tonnage of metal welded.

3. Showcase Your Technical Skills

Be prepared to discuss your technical skills in detail, including your proficiency in different welding processes (e.g., GMAW, GTAW, FCAW), materials, and welding equipment.

- Describe your experience with welding different metals, such as steel, stainless steel, and aluminum.

- Explain your understanding of welding codes and standards (e.g., ASME Boiler and Pressure Vessel Code).

4. Emphasize Safety and Quality

Safety is paramount in welding, so highlight your commitment to following safety protocols and maintaining a safe work environment. Additionally, emphasize your focus on quality by explaining your inspection and testing procedures.

- Describe your experience with welding safety equipment and procedures.

- Explain your understanding of non-destructive testing methods (e.g., visual inspection, radiography).

5. Practice Your Communication Skills

Effective communication is essential in any job, but especially in a role where you may need to interact with engineers, supervisors, and other professionals. Practice your communication skills by preparing clear and concise answers to potential interview questions.

- Practice answering questions about your welding experience and technical skills.

- Prepare questions to ask the interviewer about the company, the position, and the work environment.

6. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This conveys respect for the company and the interviewers.

- Wear clean and pressed business attire.

- Arrive at the interview location 10-15 minutes early to allow for any unexpected delays.

7. Follow Up

After the interview, send a thank-you note to the interviewers within 24 hours. This shows your appreciation for their time and reiterates your interest in the position.

- Express your gratitude for the opportunity to interview.

- Reiterate your key qualifications and how they align with the job requirements.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Certified Maintenance Welder role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.