Are you gearing up for a career in Chain Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Chain Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

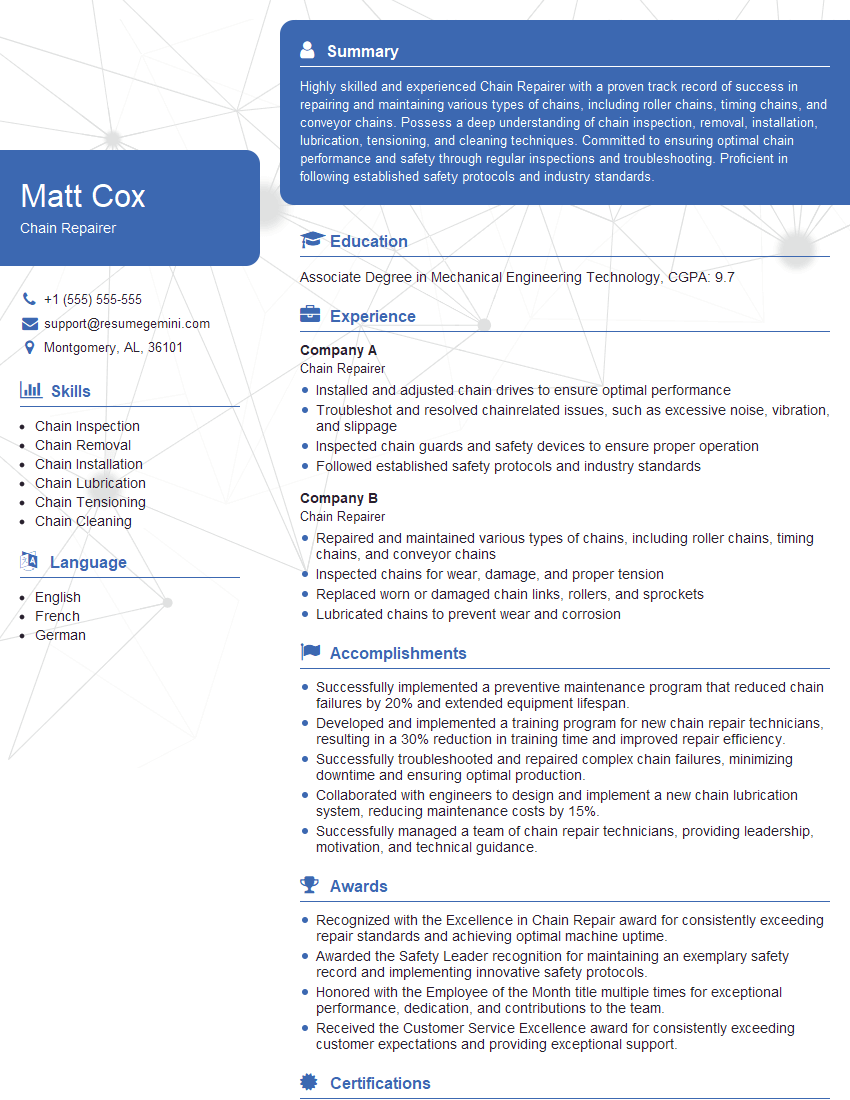

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chain Repairer

1. What are the different types of chain drives?

There are several types of chain drives, including:

- Roller chain: The most common type, consisting of a series of rollers connected by pins.

- Silent chain: Similar to roller chain but with toothed sprockets and a quieter operation.

- Inverted tooth chain: Designed for high-torque applications, with teeth on both sides of the chain.

- Leaf chain: A flat chain with leaf-shaped links, used in low-speed applications.

2. What are the key factors to consider when selecting a chain for a specific application?

Factors influencing chain selection:

- Power transmission capacity: The chain must be able to handle the load and torque requirements.

- Speed: The chain must operate at the desired speed without excessive wear or vibration.

- Environment: Consider factors such as temperature, humidity, and the presence of corrosive substances.

- Cost: The cost of the chain and its maintenance must be taken into account.

Steps involved in chain selection:

- Determine the required power transmission capacity.

- Calculate the chain speed and ensure it meets the application requirements.

- Select the appropriate chain type based on the environment and loading conditions.

- Consider the availability and cost of the chain and its components.

3. How do you determine the pitch of a chain?

The pitch of a chain is the distance between the centers of adjacent pins. It is typically measured in inches or millimeters. To determine the pitch, follow these steps:

- Locate two adjacent pins on the chain.

- Measure the distance between the centers of the pins using a ruler or caliper.

- Divide the measurement by the number of pins between the two points.

4. What are the common causes of chain failure and how can they be prevented?

Common causes of chain failure include:

- Overloading: Operating the chain beyond its rated capacity.

- Poor lubrication: Insufficient lubrication can lead to excessive wear and corrosion.

- Misalignment: Misalignment between sprockets can cause excessive wear and vibration.

- Corrosion: Exposure to corrosive substances can weaken the chain.

Prevention measures:

- Use the correct chain for the application, considering load and speed requirements.

- Ensure proper lubrication and follow the manufacturer’s recommended lubrication schedule.

- Align sprockets accurately using alignment tools.

- Protect the chain from corrosive environments or use corrosion-resistant chains.

5. Describe the process of installing and tensioning a chain drive.

Installing and tensioning a chain drive involves the following steps:

- Prepare the sprockets: Clean the sprockets and remove any burrs or debris.

- Place the chain on the sprockets: Start with the smaller sprocket and work your way up to the larger sprocket.

- Adjust the chain tension: Use a tensioner to adjust the chain tension to the manufacturer’s specifications. Proper tension ensures optimal performance and prevents premature wear.

- Lubricate the chain: Apply lubricant to the chain to reduce friction and wear.

6. What tools and equipment are essential for a Chain Repairer?

Essential tools and equipment for a Chain Repairer include:

- Chain breaker

- Chain rivet tool

- Socket and wrench set

- Alignment tools

- Tensioner

- Safety glasses

- Gloves

7. How do you troubleshoot a chain drive that is slipping?

Chain slipping can be caused by:

- Insufficient chain tension: Check the chain tension and adjust it as necessary.

- Worn or damaged sprockets: Inspect the sprockets for wear or damage and replace if needed.

- Misalignment: Verify the alignment of the sprockets and adjust if necessary.

- Overloading: Ensure that the chain is not overloaded and select a more appropriate chain if necessary.

8. What is the importance of regular chain maintenance?

Regular chain maintenance is crucial to ensure optimal performance and longevity of the chain drive. It involves:

- Cleaning: Remove dirt and debris from the chain and sprockets.

- Lubrication: Apply lubricant to reduce friction and wear.

- Inspection: Check for any signs of wear, damage, or misalignment.

- Adjustment: Adjust the chain tension as necessary to compensate for wear and maintain proper operation.

9. Describe the key differences between a roller chain and a silent chain.

Roller chain:

- Consists of a series of rollers connected by pins.

- More robust and durable.

- Higher load capacity.

- Less efficient at high speeds due to friction.

Silent chain:

- Has toothed sprockets and a chain with teeth on the inner surface.

- Quieter operation due to the meshing of teeth.

- Lower load capacity.

- More efficient at high speeds.

10. What safety precautions should be taken when working with chain drives?

Safety precautions to observe when working with chain drives include:

- Always wear protective gloves and safety glasses.

- Ensure that the machine is turned off and power is isolated before performing any maintenance.

- Use proper tools and equipment to handle and tension the chain.

- Be aware of pinch points and rotating parts.

- Keep the work area clean and free of obstacles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chain Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chain Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Chain Repairer is an hourly, non-exempt position that provides maintenance, repair, and replacement of chains in various industrial and commercial settings.

1. Chain Maintenance and Repair

Inspect and monitor chains for wear and damage

- Identify, measure, and record wear on chain components

- Lubricate chains to reduce friction and wear

2. Chain Replacement

Remove and replace worn or damaged chains

- Cut and size new chains to desired length

- Attach new chains using appropriate fasteners and tensioning methods

3. Equipment Troubleshooting

Diagnose and resolve issues related to chain systems

- Identify potential problems, such as vibration, noise, or excessive wear

- Perform adjustments, repairs, or replacements to restore equipment functionality

4. Safety and Compliance

Adhere to established safety regulations and industry best practices

- Wear appropriate personal protective equipment (PPE)

- Follow lockout/tagout procedures when working on energized equipment

Interview Tips

Preparing for an interview can help you showcase your skills and abilities effectively. Here are some preparation tips to help you ace your Chain Repairer interview.

1. Research the Company and Role

Learn about the company’s background, values, and the specific responsibilities of the Chain Repairer role. This will help you tailor your answers and demonstrate your interest in the position.

2. Highlight Your Skills and Experience

Emphasize your knowledge of chain systems, troubleshooting abilities, and safety practices. Quantify your experience whenever possible to provide concrete evidence of your skills.

3. Prepare for Common Interview Questions

Research common interview questions related to the Chain Repairer role. Practice answering these questions concisely and confidently.

- Tell me about your experience in chain repair.

- How do you troubleshoot and resolve problems with chain systems?

- Describe a time when you had to work under pressure or meet a tight deadline.

4. Ask Informed Questions

Asking insightful questions during the interview shows your engagement and interest in the role. Prepare questions about the company’s safety culture, training opportunities, and advancement possibilities.

5. Dress Appropriately and Arrive on Time

First impressions matter. Dress professionally and arrive on time for your interview. This demonstrates respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chain Repairer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!