Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chain Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chain Tender so you can tailor your answers to impress potential employers.

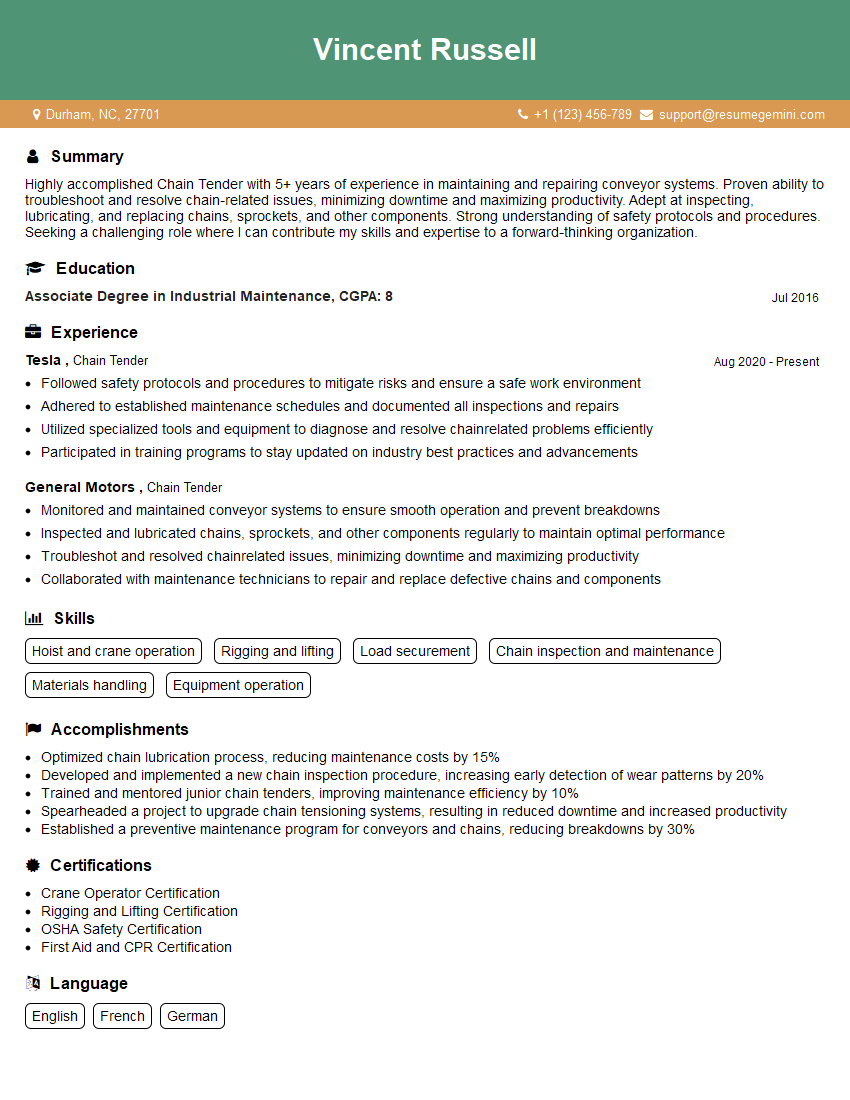

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chain Tender

1. What are the key responsibilities of a Chain Tender?

The key responsibilities of a Chain Tender typically include:

- Inspecting and maintaining chains, sprockets, and other components of mechanical systems

- Lubricating, adjusting, and cleaning machines

- Troubleshoot and repair mechanical issues

- Monitor production processes to ensure smooth operation

- Maintain production logs and records

2. What types of maintenance tasks do you perform on chains and sprockets?

- Daily inspections for wear, damage, or misalignment

- Lubrication according to manufacturer’s specifications

- Adjusting tension to ensure proper engagement

- Replacement of worn or damaged components

- Regular cleaning to remove dirt, grease, or other debris

3. How do you troubleshoot and repair chain-related problems?

To troubleshoot and repair chain-related problems, I typically:

- Identify the symptoms and determine the root cause of the issue

- Inspect the chain, sprockets, and other components for damage or wear

- Check lubrication levels and adjust as necessary

- Make necessary repairs or replacements

- Test the system to ensure proper operation

4. What safety precautions do you take when working with chains and sprockets?

When working with chains and sprockets, I always prioritize safety by:

- Wearing appropriate PPE, including gloves, safety glasses, and appropriate clothing

- Shutting down and locking out equipment before performing any maintenance

- Inspecting chains and sprockets regularly for any signs of damage or wear

- Using proper tools and techniques to avoid injury

- Following all established safety protocols and procedures

5. How do you maintain efficient operation of the machines you are responsible for?

To maintain efficient operation of the machines under my responsibility, I adhere to the following practices:

- Regularly monitoring and inspecting machines for potential issues

- Performing preventive maintenance tasks, such as lubrication, cleaning, and adjustments

- Troubleshooting and repairing any problems promptly

- Keeping detailed maintenance logs and records

- Communicating with operators and supervisors regarding machine performance and any maintenance needs

6. What types of chains and sprockets have you worked with?

Throughout my experience, I have worked with various types of chains and sprockets, including:

- Roller chains

- Silent chains

- Timing chains

- Spur gears

- Helical gears

- Bevel gears

I am familiar with their specific characteristics, applications, and maintenance requirements.

7. What is your understanding of chain tension and its importance?

Chain tension plays a crucial role in the proper functioning of chain-driven systems. I understand that:

- Correct chain tension ensures optimal power transmission and efficiency

- Proper tension minimizes wear and tear on chains, sprockets, and other components

- Over-tightening can lead to premature failure, while under-tensioning can cause chain slippage and reduced efficiency

- I use tension gauges or other methods to accurately measure and adjust chain tension

8. How do you handle situations where multiple machines require your attention simultaneously?

In scenarios where multiple machines require my attention, I prioritize tasks based on the following criteria:

- Urgency of the issue

- Potential impact on production

- Safety concerns

- I communicate effectively with operators and supervisors to coordinate efforts and minimize downtime

- I maintain a flexible and proactive approach to handle multiple responsibilities efficiently

9. What is your experience with using computerized maintenance management systems (CMMS)?

I am proficient in using CMMS to manage maintenance activities. My experience includes:

- Creating and managing work orders

- Scheduling maintenance tasks

- Tracking maintenance history

- Generating reports and analyzing data

- Using CMMS to improve maintenance efficiency and reduce downtime

10. How do you stay up-to-date with the latest advancements in chain technology?

To stay current with the latest advancements in chain technology, I engage in the following activities:

- Attend industry conferences and workshops

- Read technical journals and articles

- Consult with manufacturers and suppliers

- Participate in online forums and discussion groups

- By staying informed, I can incorporate best practices and optimize maintenance strategies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chain Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chain Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chain Tenders are responsible for inspecting, maintaining, and repairing chains, sprockets, and other related equipment. They work in a variety of industrial settings, such as manufacturing plants, construction sites, and mines.

1. Inspecting and maintaining chains and other equipment

Chain Tenders regularly inspect chains, sprockets, and other equipment to identify any signs of wear or damage. They look for cracks, rust, and other defects that could compromise the safety of the equipment.

- Inspect chains for wear, damage, and corrosion.

- Inspect sprockets for wear, damage, and misalignment.

- Inspect other related equipment, such as bearings, seals, and guards.

2. Repairing chains and other equipment

Chain Tenders repair chains, sprockets, and other equipment as needed. They use a variety of tools and techniques to repair damaged components and restore them to proper working order.

- Repair chains by replacing worn or damaged links.

- Repair sprockets by replacing worn or damaged teeth.

- Repair other related equipment, such as bearings, seals, and guards.

3. Lubricating chains and other equipment

Chain Tenders lubricate chains, sprockets, and other equipment to reduce friction and wear. They use a variety of lubricants, such as oil, grease, and dry lubricants.

- Lubricate chains regularly to reduce friction and wear.

- Lubricate sprockets regularly to reduce friction and wear.

- Lubricate other related equipment, such as bearings, seals, and guards.

4. Troubleshooting

Chain Tenders troubleshoot problems with chains, sprockets, and other equipment. They use their knowledge and experience to identify the source of the problem and find a solution.

- Troubleshooting problems with chains, sprockets, and other equipment.

- Identifying the source of the problem.

- Finding a solution to the problem.

Interview Tips

Preparing for an interview for a Chain Tender position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to learn about the specific requirements of the position.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to understand the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked in an interview for a Chain Tender position. It is a good idea to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Tell me about your experience inspecting and maintaining chains and other equipment.

- Describe a time when you had to repair a chain or other equipment.

- Why are you interested in working for our company?

3. Dress professionally

The way you dress for an interview can make a big impression on the interviewer. It is important to dress professionally and appropriately for the position you are applying for. For a Chain Tender position, you should wear clean, pressed clothes that are appropriate for a work environment.

- Wear clean, pressed clothes that are appropriate for a work environment.

- Avoid wearing clothing that is too revealing or too casual.

- Make sure your clothes fit well and are comfortable.

4. Be confident

Confidence is key in an interview. When you are confident, you are more likely to make a good impression on the interviewer and convince them that you are the right person for the job. There are a number of ways to boost your confidence before an interview, such as practicing your answers to common interview questions, dressing professionally, and preparing for the interview in advance.

- Practice your answers to common interview questions.

- Dress professionally.

- Prepare for the interview in advance.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chain Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!