Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chainstitch Elastic Attacher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

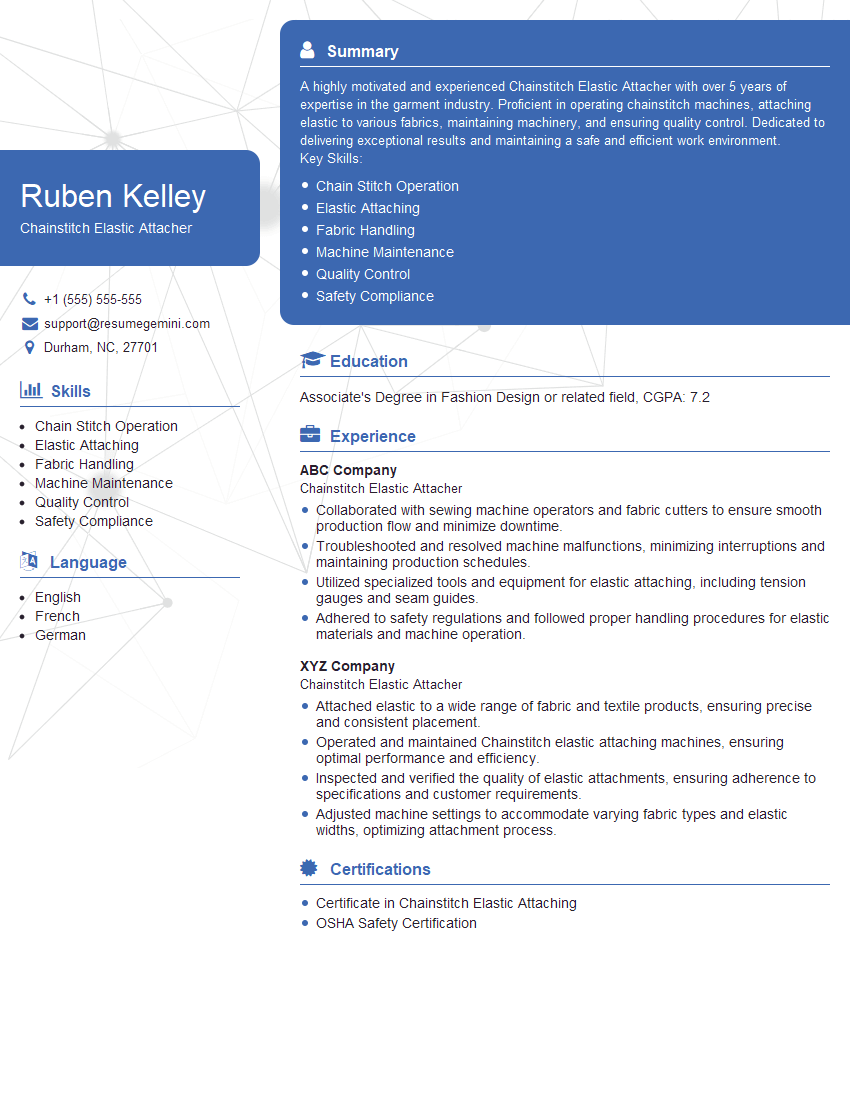

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chainstitch Elastic Attacher

1. Explain the process of attaching elastic using a chainstitch elastic attacher in detail?

Sample Answer:

- Position the elastic and fabric under the presser foot of the chainstitch elastic attacher.

- Adjust the tension and stitch length to suit the fabric and elastic.

- Start the machine and guide the fabric and elastic through the attacher, ensuring the elastic is evenly distributed.

- Monitor the stitching process and make any necessary adjustments to maintain consistent attachment.

- Trim any excess elastic after completing the attachment.

2. Describe the types of elastic commonly used in chainstitch elastic attachment and their properties?

Knitted Elastic

- Flexible and stretchable

- Lightweight and breathable

- Suitable for delicate fabrics

Woven Elastic

- Strong and durable

- Less flexible than knitted elastic

- Suitable for heavier fabrics

Braided Elastic

- Combination of knitted and woven elastic

- Good balance of flexibility and strength

- Versatile for various fabrics

3. How do you troubleshoot common issues that arise while using a chainstitch elastic attacher?

Sample Answer:

- Elastic not attaching properly: Check tension settings, needle size, and fabric compatibility.

- Uneven stitching: Adjust stitch length, tension, or guide the fabric and elastic more carefully.

- Elastic breaking during attachment: Use a different type or size of elastic, or reduce the tension.

- Machine jamming: Clean the attacher, check for any obstructions, or consult the manufacturer’s manual.

4. What safety precautions should be followed when operating a chainstitch elastic attacher?

Sample Answer:

- Wear appropriate safety gear, including eye protection and gloves.

- Keep fingers away from moving parts.

- Use sharp needles and replace them regularly.

- Unplug the machine before cleaning or maintenance.

- Follow the manufacturer’s instructions for safe operation.

5. How do you maintain a chainstitch elastic attacher to ensure optimal performance?

Sample Answer:

- Clean the attacher regularly to remove lint and debris.

- Oil moving parts as per the manufacturer’s instructions.

- Check and adjust tension settings periodically.

- Inspect needles for wear and tear and replace them as needed.

- Follow the manufacturer’s maintenance schedule for major servicing.

6. Explain the different types of stitches used in chainstitch elastic attachment?

Zigzag Stitch

- Creates an elasticated seam with a zigzag pattern

- Provides good stretch and recovery

Overlock Stitch

- Creates a secure and durable seam with an overcast edge

- Less stretch than zigzag stitch

Coverstitch

- Creates a flat, decorative seam that conceals the elastic

- Suitable for visible seams on garments

7. What factors influence the choice of stitch type in chainstitch elastic attachment?

- Fabric type and weight

- Elastic type and size

- Desired level of stretch and recovery

- Seam visibility

8. How do you calculate the amount of elastic needed for a specific project?

Sample Answer:

- Measure the length of the seam that needs elastic attachment.

- Multiply the length by a factor of 1.5 to 2 to account for stretch and recovery.

- Adjust the amount of elastic based on the fabric and elastic type used.

9. What is the role of interfacing in chainstitch elastic attachment?

- Provides stability and support to the fabric

- Prevents the elastic from stretching the fabric excessively

- Enhances the durability of the seam

10. Describe the different methods of applying interfacing in chainstitch elastic attachment?

Fusible Interfacing

- Applied with heat to bond to the fabric

- Provides a permanent, strong hold

Sew-In Interfacing

- Stitched to the fabric using a sewing machine

- Provides a more flexible and adjustable hold

Self-Adhesive Interfacing

- Has a self-adhesive backing that sticks to the fabric

- Provides a temporary or removable hold

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chainstitch Elastic Attacher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chainstitch Elastic Attacher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Chainstitch Elastic Attacher

A Chainstitch Elastic Attacher is responsible for efficiently attaching elastic to garments, ensuring that the elastic is securely fastened and the finished product meets quality standards.

1. Elastic Attachment

The primary responsibility is to operate the chainstitch elastic attaching machine to sew elastic to various types of garments such as waistbands, sleeves, and necklines.

- Set up the machine according to the garment specifications and elastic type

- Load the garment and elastic onto the machine

- Adjust the tension and stitch settings to ensure proper elastic attachment

2. Quality Control

Ensuring the quality of the finished product is crucial.

- Inspect garments before and after attaching elastic to identify any defects

- Check the tension and stitch quality to meet the required standards

- Make necessary adjustments to the machine or process to rectify any issues

3. Production

The job entails meeting production targets and maintaining efficiency.

- Work within established production schedules to complete tasks on time

- Monitor machine performance and troubleshoot any problems

- Maintain a clean and organized work area

4. Communication and Teamwork

Interacting with colleagues and supervisors is essential.

- Communicate any issues or production delays to supervisors

- Assist colleagues with machine operation or troubleshooting

- Contribute to discussions on improving processes or addressing challenges

Interview Tips for Chainstitch Elastic Attacher

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace the interview for a Chainstitch Elastic Attacher position:

1. Research the Company and Position

Take the time to learn about the company’s history, culture, and products or services. Research the specific role and its responsibilities. This knowledge will enable you to answer questions confidently and show that you have a genuine interest in the position.

- Visit the company’s website and social media pages

- Read industry publications and news articles about the company

- Talk to people in your network who may have connections to the company

2. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the job requirements. Quantify your accomplishments whenever possible. For instance, instead of saying “I operated a chainstitch elastic attaching machine,” you could say “I operated a chainstitch elastic attaching machine for five years, producing an average of 100 garments per hour with a 99% quality rating.”

- Review the job description carefully and identify the key skills and qualifications

- Prepare specific examples of your work experience that demonstrate these skills

- Practice articulating your skills and experience in a clear and concise manner

3. Practice Answering Common Interview Questions

There are certain interview questions that are commonly asked in almost every interview. By preparing answers to these questions in advance, you can feel more confident and prepared during the interview.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

- Do you have any questions for me?

4. Dress Professionally and Be Punctual

First impressions matter. Dress professionally and arrive on time for your interview. This shows the interviewer that you are respectful of their time and that you are serious about the position.

- Choose clothing that is appropriate for the company culture and industry

- Make sure your clothes are clean, pressed, and fit well

- Arrive at the interview location a few minutes early to allow yourself time to relax and prepare

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chainstitch Elastic Attacher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!