Feeling lost in a sea of interview questions? Landed that dream interview for Chainstitch Pants Outseamer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chainstitch Pants Outseamer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

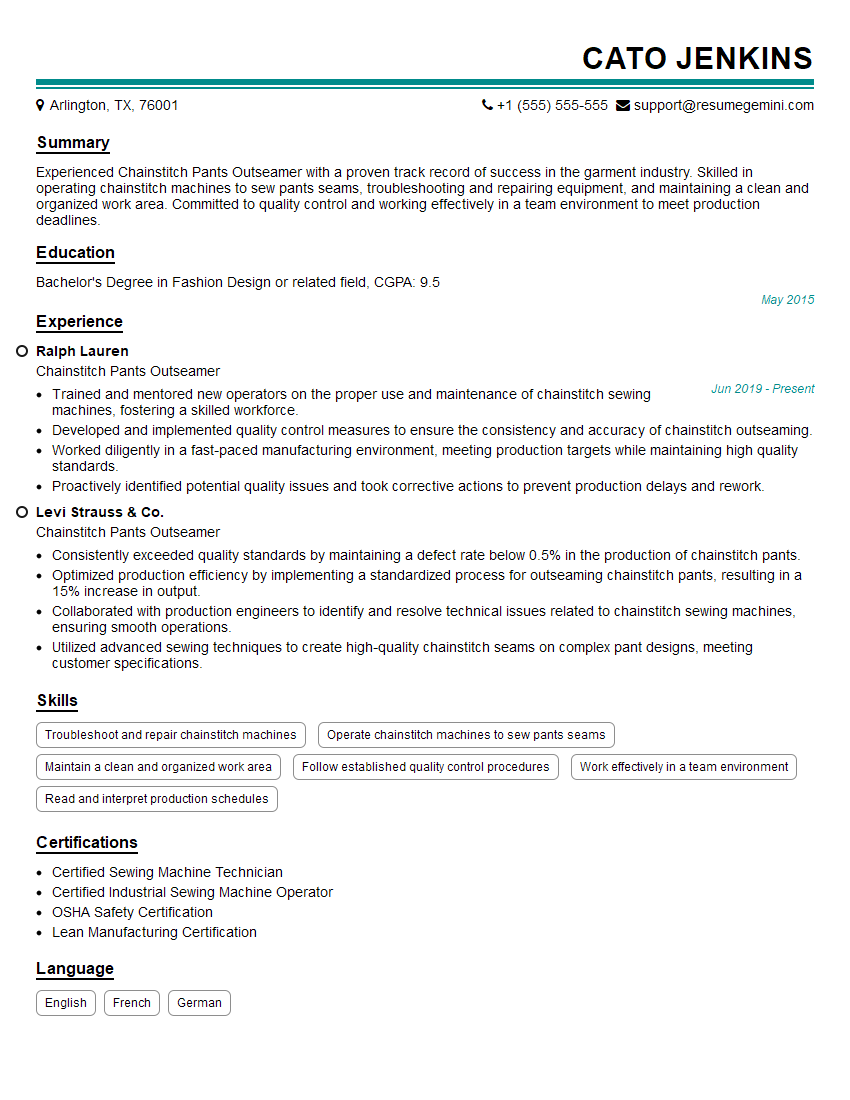

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chainstitch Pants Outseamer

1. What are the different types of chainstitch machines used in pants outseaming?

There are two main types of chainstitch machines used in pants outseaming:

- Single-needle chainstitch machines

- Double-needle chainstitch machines

2. What are the key differences between single-needle and double-needle chainstitch machines?

- Stitch type: Single-needle machines produce a single chain stitch, while double-needle machines produce two parallel chain stitches.

- Thread consumption: Double-needle machines consume twice the amount of thread as single-needle machines.

- Stitch density: Double-needle machines produce a denser stitch pattern than single-needle machines.

3. How do you adjust the stitch length and tension on a chainstitch machine?

The stitch length and tension on a chainstitch machine can be adjusted by:

- Stitch length adjustment: Adjust the stitch length knob or lever to increase or decrease the distance between stitches.

- Thread tension adjustment: Adjust the thread tension screws or dials to increase or decrease the tension on the upper and lower threads.

4. What are the common causes of skipped stitches on a chainstitch machine?

- Improper threading

- Dull or damaged needle

- Insufficient thread tension

- Bent or damaged hook assembly

5. How do you troubleshoot and repair a jammed thread in a chainstitch machine?

To troubleshoot and repair a jammed thread in a chainstitch machine:

- Identify the source of the jam: Check for tangled thread, broken needles, or damaged parts.

- Rethread the machine: Remove the jammed thread and rethread the machine correctly.

- Inspect the needle: Check the needle for damage or bending, and replace it if necessary.

- Clean the hook assembly: Remove any lint, thread, or debris from the hook assembly using a cleaning brush or compressed air.

6. What are the different types of fabric materials used in pants outseaming?

- Cotton

- Denim

- Polyester

- Nylon

- Spandex

7. How do you select the appropriate needle size and thread type for different fabric materials?

The appropriate needle size and thread type for different fabric materials are:

- Cotton: Size 10 or 12 needle, cotton thread

- Denim: Size 14 or 16 needle, denim thread

- Polyester: Size 12 or 14 needle, polyester thread

- Nylon: Size 12 or 14 needle, nylon thread

- Spandex: Size 10 or 12 needle, stretch thread

8. What are the safety precautions that should be observed when operating a chainstitch machine?

- Wear appropriate safety gear, including safety glasses and gloves.

- Keep the work area clean and free of tripping hazards.

- Never reach into the moving parts of the machine while it is operating.

- Turn off the machine and unplug it before performing any maintenance or cleaning.

9. How do you maintain and clean a chainstitch machine?

To maintain and clean a chainstitch machine:

- Daily maintenance: Clean the machine with a soft brush or compressed air to remove lint and thread scraps.

- Weekly maintenance: Lubricate the machine according to the manufacturer’s instructions.

- Monthly maintenance: Inspect and clean the hook assembly, needle plate, and other moving parts for wear or damage.

10. Describe your experience and skills in operating chainstitch machines for pants outseaming.

I have been operating chainstitch machines for pants outseaming for the past [number] years. I am proficient in operating both single-needle and double-needle machines, and I have experience working with a variety of fabric materials, including cotton, denim, and polyester. I am also skilled in adjusting the stitch length and tension, troubleshooting and repairing common problems, and maintaining and cleaning the machines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chainstitch Pants Outseamer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chainstitch Pants Outseamer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Chainstitch Pants Outseamer

The Chainstitch Pants Outseamer plays a crucial role in the manufacturing process of denim and other pants, ensuring the production of high-quality garments. Here are the key responsibilities of this position:

1. Operate Chainstitch Outseam Machine

The primary responsibility of the Chainstitch Pants Outseamer is to operate the chainstitch outseam machine efficiently and effectively. This involves:

- Loading and positioning fabrics or pants into the machine correctly.

- Setting up and adjusting the machine parameters to achieve optimal stitching quality.

- Monitoring the stitching process, ensuring consistent and precise outseams.

- Identifying and resolving any machine malfunctions or production issues promptly.

2. Maintain Work Area and Machine

To ensure a safe and efficient work environment, the Chainstitch Pants Outseamer is responsible for maintaining both their work area and the chainstitch outseam machine. This includes:

- Keeping the work area clean and organized, minimizing tripping or slipping hazards.

- Conducting regular maintenance and inspection of the machine, ensuring optimal performance.

- Performing minor repairs or adjustments to the machine as necessary.

- Reporting any major issues or equipment failures to the supervisor promptly.

3. Quality Control and Inspection

The Chainstitch Pants Outseamer plays a vital role in ensuring the quality of the finished pants. Their responsibilities include:

- Inspecting the finished outseams for any defects or inconsistencies.

- Identifying and correcting any stitching errors or fabric imperfections.

- Maintaining records of quality checks and reporting any quality concerns to the supervisor.

- Following established quality standards and procedures to ensure the production of high-quality garments.

4. Teamwork and Communication

The Chainstitch Pants Outseamer works as part of a team and communicates effectively with colleagues and supervisors.

- Collaborating with other team members to ensure smooth production flow.

- Communicating any production issues or delays to the supervisor promptly.

- Providing feedback and suggestions for improving production processes.

- Adhering to safety protocols and reporting any potential hazards or concerns.

Interview Preparation Tips:

To ace your interview for the Chainstitch Pants Outseamer position, consider the following preparation tips:

1. Research the Company and Industry

Demonstrate your eagerness to learn about the company by researching its history, values, and current projects. Understanding the company’s culture and the denim manufacturing industry shows your dedication and interest in the role.

2. Practice Talking About Your Experience

Prepare specific examples of how your skills and experience align with the key responsibilities of the Chainstitch Pants Outseamer. Emphasize your ability to operate chainstitch outseam machines, maintain a clean work environment, and ensure quality control. Providing concrete examples will showcase your capabilities.

3. Prepare for Technical Questions

Be ready to answer technical questions related to chainstitch outseam machines, fabric types, and quality control processes. Research common techniques and best practices to demonstrate your knowledge and understanding of the field.

4. Dress Professionally and Punctually

First impressions matter. Dress professionally and arrive on time for your interview. Your appearance and punctuality convey respect for the interviewer and the company.

5. Ask Questions

At the end of the interview, show your engagement by asking thoughtful questions. This demonstrates your genuine interest in the position and the company. Consider asking about the company’s training programs, quality standards, or future growth opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chainstitch Pants Outseamer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!