Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chair Frame Builder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

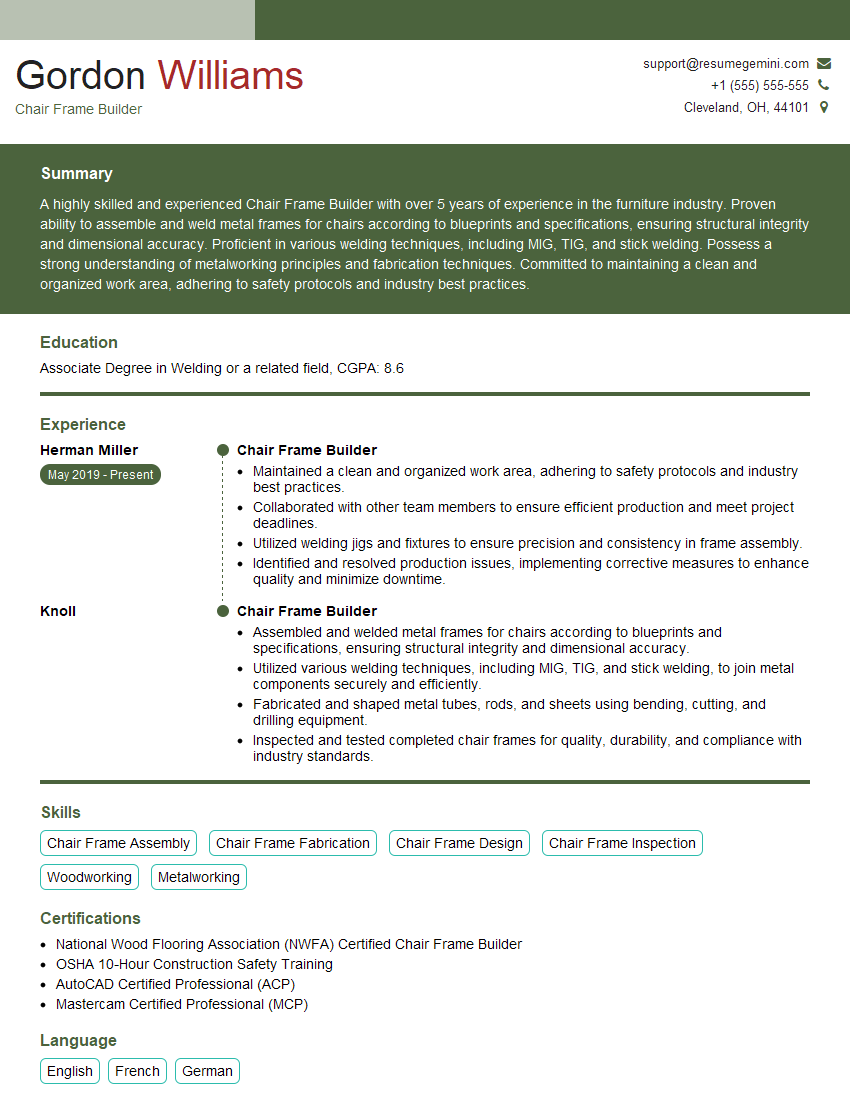

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chair Frame Builder

1. What are the critical steps involved in building a chair frame?

- Design or obtain a design for the chair frame.

- Select the appropriate materials for the frame, such as wood, metal, or plastic.

- Cut the materials to the specified lengths and shapes.

- Assemble the frame components using joinery techniques such as mortise and tenon, dowels, or screws.

- Reinforce the joints for added strength and stability.

- Apply finishing touches such as sanding, staining, or painting.

- Quality control and inspection to ensure the frame meets specifications.

2. How do you determine the strength and durability of a chair frame?

- Material selection: Consider the strength and durability of the materials used, such as hardwood versus softwood.

- Joint design: Choose joinery methods that provide a strong and secure connection between frame components.

- Reinforcement: Determine the need for additional reinforcement, such as gussets, braces, or cross-members.

- Stress testing: Conduct physical tests, such as weight-bearing tests, to assess the frame’s ability to withstand anticipated loads.

- Industry standards: Adhere to established industry standards and guidelines to ensure the frame meets minimum strength requirements.

3. What tools and equipment are essential for chair frame building?

- Measuring and marking tools: tape measure, ruler, pencil

- Cutting tools: saw, miter saw, router

- Joining tools: drill, screwdriver, hammer, clamps

- Sanding tools: sandpaper, orbital sander

- Finishing tools: brushes, spray gun

- Specialty tools: doweling jig, biscuit joiner

- Safety equipment: safety glasses, dust mask, gloves

4. How do you ensure precision and accuracy in chair frame construction?

- Accurate measurements: Use calibrated measuring tools and double-check measurements before cutting or assembling.

- Jigs and templates: Employ jigs and templates to guide cutting and ensure consistent dimensions.

- Clamping and alignment: Use clamps to hold components securely in place and ensure proper alignment during assembly.

- Dry-fitting: Assemble the frame without glue or fasteners first to check for fit and identify any areas that need adjustment.

- Precision tools: Utilize precision tools, such as a table saw with a fence, to achieve accurate cuts and joints.

5. Describe the different types of wood used for chair frame construction and their advantages and disadvantages.

- Advantages: Durability, strength, stability, aesthetic appeal

- Disadvantages: Higher cost, heavier weight

- Examples: Oak, maple, cherry

- Advantages: Lower cost, lighter weight, ease of working

- Disadvantages: Less durable, less strong

- Examples: Pine, fir, cedar

- Advantages: Consistent quality, dimensional stability, eco-friendly

- Disadvantages: May lack the aesthetic appeal of natural wood

- Examples: Plywood, MDF

Hardwoods

Softwoods

Engineered Wood

6. How do you handle different types of joints in chair frame construction?

- Mortise and tenon joint: Strong and durable, used for structural connections.

- Dowel joint: Simple and effective, suitable for smaller components.

- Biscuit joint: Quick and strong, uses a biscuit joiner to align and join pieces.

- Corner block joint: Adds strength to corners, especially for frames with mitered edges.

- Pocket hole joint: Concealed joint made using a pocket hole jig and screws.

7. What are the safety precautions that must be taken when operating woodworking machinery?

- Wear proper safety gear, including safety glasses, earplugs, and gloves.

- Keep the work area clean and free of debris.

- Inspect tools and equipment regularly for damage or malfunction.

- Never operate machinery while under the influence of alcohol or drugs.

- Follow all manufacturer’s instructions for safe operation.

- Be aware of potential hazards, such as kickback, flying wood chips, and sharp edges.

8. What are the common problems that can occur during chair frame construction and how do you troubleshoot them?

- Loose joints: Check the joint type and reinforcement, tighten screws or glue if necessary.

- Uneven legs: Measure the legs and adjust by sanding or adding shims.

- Cracking or splitting wood: Use stronger wood, reinforce joints, or adjust moisture content.

- Difficult assembly: Check for misaligned components, dry-fit first, and use clamps to assist assembly.

- Poor finish: Sand thoroughly, apply multiple coats of finish, and allow ample drying time.

9. What is the role of quality control in chair frame production?

- Inspect raw materials for defects.

- Monitor production processes to ensure accuracy and consistency.

- Conduct random inspections of finished frames to identify any non-conformities.

- Maintain quality records and make recommendations for improvement.

- Work with suppliers and customers to address quality issues.

10. Describe your experience in optimizing chair frame designs for cost, strength, and aesthetics.

- Analyzed existing designs to identify areas for improvement.

- Explored alternative materials and joinery methods to reduce costs and maintain strength.

- Collaborated with designers to create aesthetically pleasing frames that met functional requirements.

- Tested and evaluated prototypes to ensure performance and durability.

- Implemented design changes to improve assembly efficiency and reduce production time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chair Frame Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chair Frame Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chair Frame Builders play a crucial role in the manufacturing process by constructing the skeletal framework of chairs, which serves as the foundation for the overall structure, comfort, and durability of the chair.

1. Frame Assembly

Assemble and build chair frames from various materials such as wood, metal, or plastic, ensuring accuracy and precision.

- Read and interpret blueprints and specifications to determine the exact specifications of the chair frame to be built.

- Select and measure appropriate materials based on the design requirements.

- Cut and shape materials using specialized tools and equipment, ensuring precise dimensions and angles.

- Join and assemble frame components using techniques such as welding, nailing, or gluing, ensuring structural integrity.

- Reinforce and strengthen the frame to withstand expected weight and stress.

2. Quality Control

Inspect and evaluate the quality of assembled chair frames to ensure adherence to specifications and industry standards.

- Conduct visual inspections to identify defects or imperfections in the frame.

- Perform dimensional checks to verify the accuracy of measurements and angles.

- Test the strength and durability of the frame by applying weight or force.

- Identify areas for improvement and suggest modifications to enhance the quality of the frames.

- Maintain accurate records of quality checks and report any non-conformances to supervisors.

3. Maintenance and Repair

Perform maintenance and repairs on chair frames to ensure their continued functionality and safety.

- Identify and diagnose problems with chair frames, such as loose joints or damaged components.

- Disassemble and repair frames using appropriate tools and techniques.

- Replace damaged or worn components with new ones, ensuring proper fit and alignment.

- Conduct preventive maintenance checks to identify potential problems and take corrective actions.

- Maintain a clean and organized work area, ensuring safety and efficiency.

4. Safety Compliance

Follow established safety protocols and regulations to ensure a safe work environment.

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Operate machinery and equipment according to safety guidelines.

- Handle and store materials properly to prevent accidents.

- Report any safety hazards or concerns to supervisors.

- Stay informed about safety updates and participate in safety training programs.

Interview Tips

To ace the interview for a Chair Frame Builder position, it is essential to prepare thoroughly and showcase your skills and experience that align with the key job responsibilities:

1. Highlight Your Technical Expertise

Emphasize your proficiency in assembling and constructing chair frames using different materials and techniques.

- Provide specific examples of projects where you successfully built complex or customized chair frames.

- Quantify your accomplishments by mentioning the number of frames assembled or the production rate achieved.

- Discuss your understanding of different joinery techniques, such as welding, nailing, or gluing, and explain how you ensure structural integrity.

2. Demonstrate Your Quality Focus

Describe your commitment to quality and your ability to inspect and evaluate chair frames meticulously.

- Share examples of your quality control procedures and how you maintain accuracy and precision in your work.

- Explain how you identify and address non-conformances to ensure that chair frames meet specifications.

- Discuss your knowledge of industry standards and regulations related to chair frame construction.

3. Showcase Your Problem-Solving Abilities

Highlight your ability to troubleshoot and repair chair frames efficiently and effectively.

- Provide examples of how you diagnosed and resolved problems with chair frames, such as loose joints or damaged components.

- Explain your approach to preventive maintenance and how you identify potential issues to avoid breakdowns.

- Discuss your knowledge of different repair techniques and how you select the most appropriate method for each situation.

4. Emphasize Your Safety Consciousness

Stress your commitment to safety and your understanding of workplace safety protocols.

- Describe your experience in operating machinery and equipment safely.

- Explain how you handle and store materials properly to prevent accidents.

- Discuss your understanding of emergency procedures and your role in maintaining a safe work environment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chair Frame Builder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.