Are you gearing up for an interview for a Chalk Molding Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chalk Molding Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

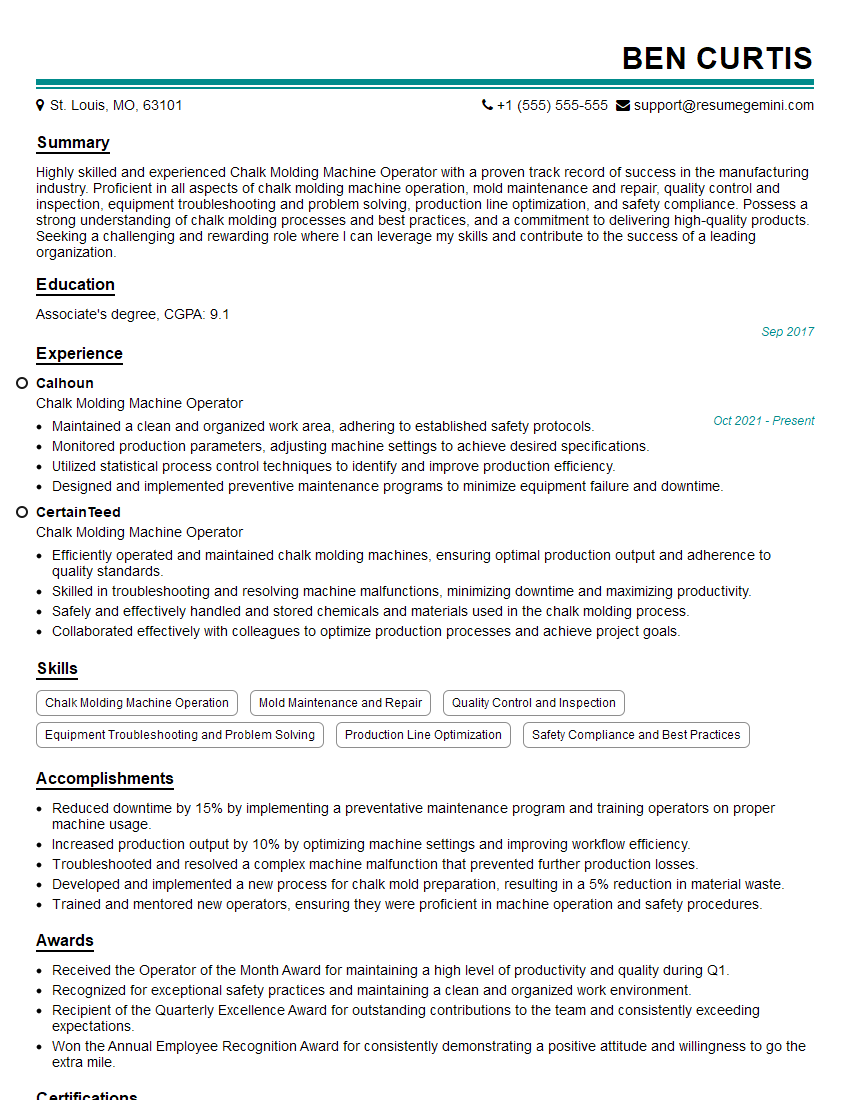

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chalk Molding Machine Operator

1. Describe the process of operating a chalk molding machine?

- Load the machine with chalk powder and water.

- Set the machine to the correct speed and pressure.

- Monitor the machine as it molds the chalk.

- Inspect the finished chalk and make any necessary adjustments.

- Clean the machine after each use.

2. What are the different types of chalk molding machines available?

Manual Machines:

- Requires operator to manually fill and operate the machine.

- Lower production rate compared to automated machines.

Semi-Automated Machines:

- Partially automated functions, such as automatic filling or ejection.

- Higher production rate than manual machines.

Fully Automated Machines:

- Completely automated process, from filling to ejection.

- Highest production rate and efficiency.

3. What are the most common problems that can occur when operating a chalk molding machine?

- Chalk powder not flowing properly.

- Machine not molding chalk correctly.

- Finished chalk not meeting specifications.

- Machine breakdowns.

- Safety hazards, such as moving parts or electrical issues.

4. How do you troubleshoot and resolve common problems with a chalk molding machine?

- Identify the problem and its possible causes.

- Check the machine’s settings and make sure they are correct.

- Inspect the machine for any damage or wear and tear.

- Clean the machine if necessary.

- Replace any worn or damaged parts.

- Follow the manufacturer’s instructions for troubleshooting and repairs.

5. What are the safety precautions that must be taken when operating a chalk molding machine?

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Follow all operating instructions carefully.

- Keep hands and other body parts away from moving parts.

- Do not operate the machine if it is damaged or not functioning properly.

- Keep the work area clean and free of debris.

- Be aware of potential hazards, such as electrical shocks or pinch points.

6. What is the importance of regular maintenance for a chalk molding machine?

- Extends the life of the machine.

- Reduces the risk of breakdowns and costly repairs.

- Ensures optimal performance and efficiency.

- Maintains safety standards and minimizes potential hazards.

- Improves productivity and profitability.

7. Can you describe the different types of chalk that can be produced using a chalk molding machine?

- School chalk: Used for writing on chalkboards.

- Tailor’s chalk: Used for marking fabric.

- Artist’s chalk: Used for drawing and sketching.

- Sidewalk chalk: Used for drawing on sidewalks and playgrounds.

- Industrial chalk: Used for various industrial applications, such as abrasives and polishing.

8. What are the key factors that affect the quality of molded chalk?

- Quality of chalk powder

- Molding pressure

- Molding temperature

- Drying conditions

- Storage conditions

9. How do you ensure that the molded chalk meets the required specifications?

- Follow standardized operating procedures.

- Monitor machine settings and chalk quality.

- Conduct regular inspections and testing.

- Make necessary adjustments to the process.

- Document and maintain quality records.

10. What is your experience in managing a team of chalk molding machine operators?

- Supervised a team of operators responsible for producing high-quality chalk.

- Provided training and guidance to new operators.

- Ensured that all operators followed safety protocols and operating procedures.

- Coordinated with other departments to ensure efficient production and quality control.

- Implemented continuous improvement initiatives to enhance productivity and reduce costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chalk Molding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chalk Molding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chalk Molding Machine Operators are responsible for operating and maintaining chalk molding machines, which produce chalk sticks for use in schools, offices, and other settings.

1. Machine Operation

Chalk Molding Machine Operators are responsible for:

- Setting up and operating chalk molding machines

- Monitoring machine performance and making adjustments as needed

- Ensuring that the chalk sticks are produced to the correct specifications

2. Machine Maintenance

Chalk Molding Machine Operators are also responsible for:

- Performing regular maintenance on chalk molding machines

- Identifying and troubleshooting problems

- Making minor repairs as needed

3. Quality Control

Chalk Molding Machine Operators are responsible for:

- Inspecting chalk sticks for defects

- Ensuring that the chalk sticks meet the required quality standards

- Rejecting chalk sticks that do not meet the required quality standards

4. Safety

Chalk Molding Machine Operators are responsible for:

- Following all safety procedures

- Wearing appropriate personal protective equipment

- Maintaining a clean and safe work area

Interview Tips

To prepare for an interview for a Chalk Molding Machine Operator position, you should:

1. Research the Company

Learn as much as you can about the company, its products, and its culture. This will help you to answer questions about why you are interested in the position and how you can contribute to the company.

2. Practice Answering Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Practice answering these questions in a clear and concise way.

3. Prepare Questions for the Interviewer

Asking questions at the end of the interview shows that you are interested in the position and that you are taking the interview seriously. Prepare a few questions about the position, the company, or the industry.

4. Dress Professionally

First impressions matter, so make sure to dress appropriately for the interview. This means wearing clean, pressed clothes and shoes.

5. Be Confident and Enthusiastic

Believe in yourself and your abilities. Be enthusiastic about the position and show the interviewer that you are excited about the opportunity to work for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chalk Molding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!