Are you gearing up for an interview for a Chassis Wirer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chassis Wirer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

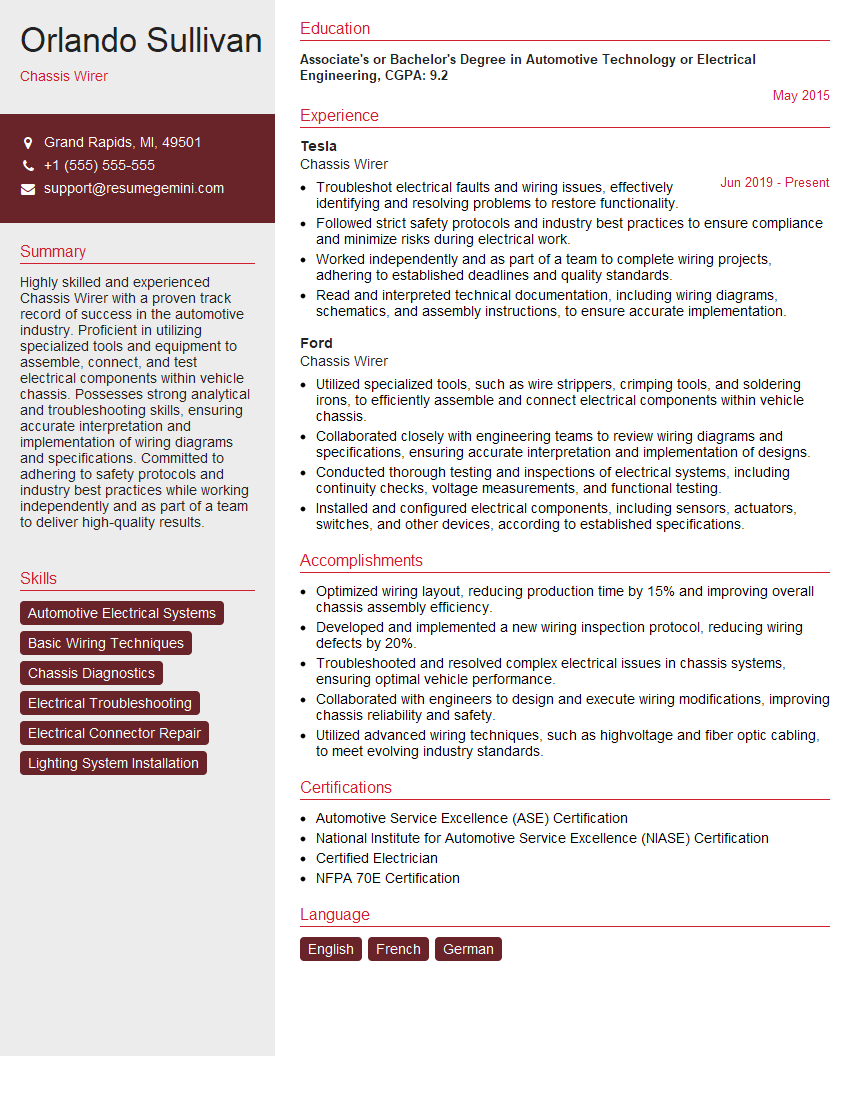

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chassis Wirer

1. Explain the process of wire harness installation in a vehicle chassis?

- Review the wiring diagram to understand the layout and connections.

- Identify and locate the mounting points for the wire harness.

- Route the harness along the designated path, ensuring proper clearance from other components.

- Secure the harness to the chassis using appropriate fasteners, such as clamps or zip ties.

- Connect the wire harness to the electrical components, such as sensors, actuators, and modules.

- Inspect and test the wire harness to ensure proper functionality.

2. What are the different types of wire used in chassis wiring?

Conductors

- Copper: High conductivity and flexibility

- Aluminum: Lightweight and cost-effective

Insulation

- PVC: Polyvinyl chloride, common and economical

- XLPE: Cross-linked polyethylene, higher temperature resistance

- Teflon: Polytetrafluoroethylene, excellent electrical and thermal properties

3. Describe the use of wire strippers and crimpers in chassis wiring?

- Used to remove insulation from the ends of wires.

- Ensure precise stripping length to prevent short circuits or exposed conductors.

- Used to create secure and reliable electrical connections.

- Different crimping tools for various types of terminals and connectors.

Wire Strippers:

Crimpers:

4. How do you ensure the quality of wire harness assemblies?

- Follow specified procedures and standards.

- Use high-quality materials and components.

- Perform inspections and testing throughout the assembly process.

- Implement quality control measures, such as statistical process control.

- Obtain necessary certifications, such as ISO 9001.

5. What are the safety precautions to consider when working with chassis wiring?

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Isolate power sources before working on the wiring.

- Use insulated tools and ensure proper grounding.

- Follow lockout/tagout procedures to prevent accidental energization.

- Be aware of potential electrical hazards and take necessary precautions.

6. Explain the use of wire labels and markers in chassis wiring?

- Identify and trace wires for easier troubleshooting and maintenance.

- Conform to industry standards and company guidelines for wire marking.

- Use durable and readable labels that withstand harsh automotive environments.

- Document wire connections and routing for future reference.

7. Describe the process of troubleshooting electrical faults in chassis wiring?

- Identify the symptoms and affected components.

- Perform visual inspections for loose connections, damaged wires, or burnt components.

- Use diagnostic tools, such as multimeters and oscilloscopes, to measure voltage, resistance, and current.

- Trace the wiring and check continuity to locate faults.

- Repair or replace faulty components and reassemble the system.

8. What are the key differences between CAN and LIN bus systems used in automotive wiring?

Controller Area Network (CAN)

- High-speed communication protocol

- Used for critical systems and data exchange

Local Interconnect Network (LIN)

- Low-speed communication protocol

- Suitable for cost-sensitive applications

9. Explain the importance of proper grounding in chassis wiring?

- Provides a reference point for electrical circuits.

- Protects against electrical noise and interference.

- Reduces the risk of electrical faults and component damage.

- Ensures proper operation of electronic systems.

10. Describe the use of harnesses and connectors in chassis wiring?

Harnesses:

- Organize and protect multiple wires.

- Simplify installation and maintenance.

Connectors:

- Establish electrical connections between different components.

- Allow for easy disconnection and reconnection.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chassis Wirer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chassis Wirer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Chassis Wirer plays a pivotal role in the construction of various chassis components, ensuring their electrical integrity and functionality. Key job responsibilities encompass:

1. Electrical Assembly and Wiring

Efficiently assemble and wire electrical components, ensuring strict adherence to schematics and wiring diagrams.

- Install and connect wiring, connectors, and electrical components on chassis frames.

- Inspect and ensure the proper operation of all electrical systems prior to assembly.

2. Testing and Verification

Conduct thorough testing and verification procedures to guarantee the accuracy and functionality of electrical systems.

- Carry out electrical continuity and insulation resistance tests.

- Confirm the proper operation of lighting, sensors, and other electrical devices.

3. Troubleshooting and Repair

Effectively troubleshoot electrical issues and implement appropriate repair measures to maintain system integrity.

- Identify and resolve electrical faults, including shorts, open circuits, and ground faults.

- Repair or replace faulty electrical components and wiring.

4. Documentation and Compliance

Maintain accurate documentation and ensure compliance with electrical standards and safety protocols.

- Prepare and update wiring diagrams, maintenance records, and inspection reports.

- Adhere to industry standards, safety guidelines, and regulatory requirements.

Interview Tips

To ace the Chassis Wirer interview, candidates should embrace the following tips:

1. Research and Preparation

Thoroughly research the company, its products, and the specific role to demonstrate your interest and understanding.

- Review the job description and identify key responsibilities and skills.

- Explore the company’s website and social media platforms to gain insights into its culture and values.

2. Highlight Relevant Experience and Skills

Emphasize your experience and qualifications that are directly relevant to the Chassis Wirer role.

- Quantify your accomplishments using measurable results whenever possible.

- Share examples of projects where you demonstrated your skills in electrical assembly, testing, and troubleshooting.

3. Practice Common Interview Questions

Prepare for potential interview questions and practice answering them effectively.

- Anticipate questions about electrical standards, safety protocols, and testing procedures.

- Consider questions that assess your problem-solving abilities and troubleshooting experience.

4. Dress Professionally and Be Punctual

Convey professionalism by dressing appropriately and arriving on time for the interview.

- Opt for business attire that is clean, pressed, and fits well.

- Plan your journey in advance to ensure prompt arrival and minimize stress.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chassis Wirer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chassis Wirer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.