Are you gearing up for a career in Check Embosser? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Check Embosser and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

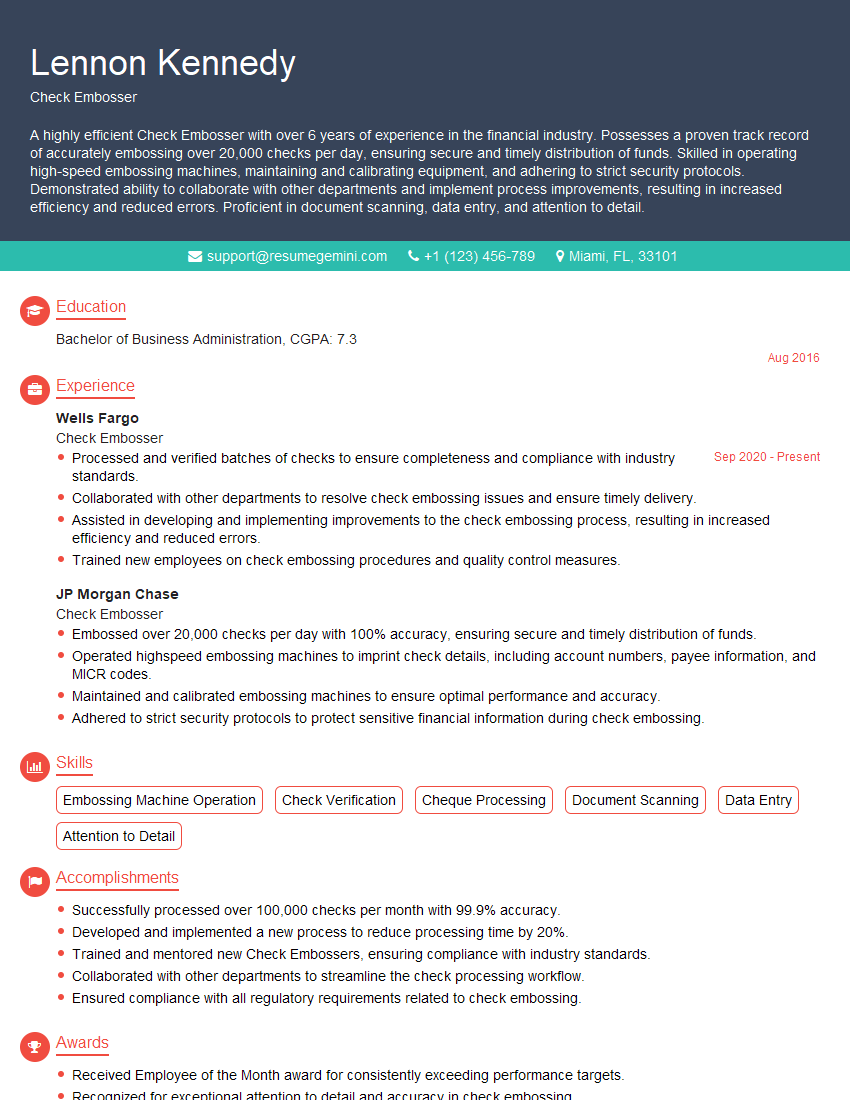

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Check Embosser

1. Embossing process requires preparing a die for embosser machine. How do you prepare the die?

The preparation of a die for an embosser machine involves several steps:

- Design creation: Create the design of the embossing image using software or a physical sample.

- Die engraving: Transfer the design onto a metal plate using a CNC engraving machine or manual tools, ensuring precision and accuracy.

- Hardening and tempering: Heat treat the metal plate to increase its hardness and durability, making it resistant to wear and tear.

- Mounting and alignment: Secure the die onto the embosser machine and align it precisely to ensure proper embossing.

2. Embossing parameters such as temperature, pressure, and speed are critical. How do you determine the optimal settings for different types of checks?

Material and design considerations:

- Consider the thickness and composition of the check paper, as well as the complexity of the embossing design.

- Adjust temperature and pressure accordingly to ensure clear and consistent embossing without damaging the check.

Testing and experimentation:

- Perform test runs with different parameter combinations.

- Evaluate the results for clarity, depth, and accuracy of the embossing.

- Fine-tune the settings based on the test results to achieve optimal quality.

3. During embossing, you encounter a problem with uneven pressure distribution. How do you troubleshoot and resolve the issue?

- Inspect the embossing machine: Check for any mechanical issues or misalignment of components within the machine.

- Examine the die: Ensure that the die is properly mounted and aligned, without any damage or wear.

- Adjust pressure settings: Calibrate the pressure settings on the machine to ensure even distribution of force across the entire die surface.

- Inspect the check paper: Verify that the check paper is of consistent thickness and free from any irregularities that could affect pressure distribution.

4. How do you maintain and calibrate the embosser machine to ensure consistent embossing quality?

Maintaining and calibrating the embosser machine is crucial for consistent embossing quality:

- Regular cleaning: Clean the machine regularly to remove any dust, debris, or ink residue that can affect performance.

- Lubrication: Lubricate moving parts according to the manufacturer’s specifications to minimize friction and ensure smooth operation.

- Calibration: Perform periodic calibration of the machine to ensure accurate temperature, pressure, and speed settings.

- Monitoring: Monitor the machine during operation for any unusual sounds or vibrations that may indicate potential issues.

5. In a high-volume embossing environment, how do you prioritize and manage multiple embossing jobs simultaneously?

- Job scheduling: Plan and schedule embossing jobs based on their timelines and importance.

- Machine allocation: Assign embosser machines to jobs based on their capabilities and capacity.

- Prioritization: Identify and prioritize critical jobs that require urgent attention.

- Communication: Communicate with clients and stakeholders to keep them informed about job progress and potential delays.

6. How do you handle the security and confidentiality of sensitive check information during embossing?

- Secure storage: Store sensitive check information in a secure and controlled environment.

- Limited access: Restrict access to check data only to authorized personnel.

- Encryption: Encrypt check information during transmission and storage to prevent unauthorized access.

- Compliance: Adhere to industry regulations and standards for handling sensitive data.

7. What techniques do you use to detect and prevent counterfeit checks from being embossed?

- Anti-counterfeit features: Incorporate security features into the check design, such as holograms, watermarks, and UV-sensitive inks.

- Die inspection: Regularly inspect embossing dies for signs of tampering or unauthorized modifications.

- Embossing quality control: Implement quality control measures to identify and reject checks with suspicious or irregular embossing.

- Training: Train staff to recognize and report potential counterfeit checks.

8. How do you stay updated on the latest advancements and best practices in embossing technology?

- Industry conferences and seminars: Attend industry events to learn about new technologies and techniques.

- Online research: Conduct research online to stay informed about the latest developments in embossing technology.

- Collaboration with vendors: Consult with vendors and industry experts to gain insights into the latest advancements.

- Continuing education: Pursue continuing education opportunities to enhance knowledge and skills in embossing techniques.

9. How do you handle situations where the embossing machine is experiencing technical difficulties?

- Troubleshooting: Identify and diagnose the technical issue based on error codes or observation.

- Repair or maintenance: Perform necessary repairs or maintenance tasks to resolve the issue.

- Escalation: If unable to resolve the issue, escalate the problem to a supervisor or technical support for assistance.

- Alternative arrangements: Explore alternative options for embossing, such as using a backup machine or outsourcing the job to a third party.

10. Can you describe a situation where you successfully resolved a complex embossing issue that required out-of-the-box thinking?

Describe a specific scenario where you encountered a challenging embossing issue and how you applied creative problem-solving to find a solution.

- Problem description: Provide a detailed description of the issue, including symptoms and potential causes.

- Troubleshooting process: Explain the steps taken to identify and diagnose the root cause of the issue.

- Solution: Describe the out-of-the-box thinking and innovative approach used to resolve the problem.

- Results: Explain the successful outcome of the solution and any positive impact on embossing quality or efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Check Embosser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Check Embosser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Check Embosser is responsible for the task of embossing checks and other financial documents with required details. The details are embossed in a raised format on the surface of the document using a machine. The role requires precision, attention to detail, and a strong understanding of the embossing process.

1. Embossing Checks and Documents

Embossing checks and other financial documents is one of the primary tasks of a Check Embosser. They use a machine to imprint raised characters on the surface of the document. These characters typically include the check number, account number, and other relevant information.

- Operate embossing machines to imprint raised characters on checks and other financial documents.

- Ensure that the embossed information is accurate and legible.

2. Preparing Documents for Embossing

Before embossing documents, Check Embossers prepare them to ensure the embossing process is successful. This preparation may involve verifying the accuracy of the information to be embossed, checking for any errors or discrepancies, and ensuring that the documents are properly aligned in the embossing machine.

- Verify the accuracy of the information to be embossed.

- Check for any errors or discrepancies in the information.

- Ensure that the documents are properly aligned in the embossing machine.

3. Maintaining and Calibrating Embossing Equipment

To ensure the smooth and efficient operation of the embossing process, Check Embossers are responsible for maintaining and calibrating the embossing equipment. This includes regular cleaning, lubrication, and adjustment of the machine to ensure that it produces high-quality embossed documents.

- Clean and lubricate embossing machines regularly.

- Adjust the embossing machine to ensure that it produces high-quality embossed documents.

- Calibrate the embossing machine to ensure that the embossed information is accurate and legible.

4. Quality Control and Compliance

Check Embossers are responsible for ensuring the quality of the embossed documents and adhering to established standards and compliance requirements. They inspect the embossed documents for any errors, defects, or inconsistencies and take corrective actions as necessary.

- Inspect embossed documents for any errors, defects, or inconsistencies.

- Take corrective actions to address any errors, defects, or inconsistencies.

- Adhere to established standards and compliance requirements related to the embossing process.

Interview Tips

To ace an interview for a Check Embosser position, it’s essential to prepare thoroughly and showcase your relevant skills and experience. Here are a few tips to help you stand out during the interview process:

1. Highlight Your Attention to Detail

Emphasize your meticulous nature and keen eye for detail. Provide examples of how you have successfully completed tasks that required precision and accuracy. Discuss your ability to identify and correct errors, ensuring the final product meets high standards.

- Example: “In my previous role, I was responsible for proofreading essential financial documents. I meticulously reviewed each document, identifying and correcting any errors in grammar, spelling, and numerical values, ensuring their accuracy and professionalism.”

2. Demonstrate Your Understanding of Embossing Techniques

Research the embossing process and different techniques used in the industry. Show the interviewer that you have a solid understanding of the equipment, materials, and safety protocols involved in embossing. If you have prior experience in embossing, be sure to highlight your proficiency.

- Example: “I have extensive experience operating both manual and automated embossing machines. I am familiar with various embossing techniques, including raised, recessed, and foil stamping. I also have a deep understanding of the safety guidelines and maintenance procedures associated with embossing equipment.”

3. Emphasize Your Commitment to Quality Assurance

Stress your commitment to producing high-quality embossed documents. Explain how you maintain accuracy and consistency in your work. Describe your experience in implementing quality control measures and your ability to identify and resolve any potential issues that may arise during the embossing process.

- Example: “In my previous role, I developed and implemented a quality control system for embossed checks. I established clear guidelines for acceptable embossing standards and conducted regular inspections to ensure compliance. My efforts significantly reduced the number of errors and improved the overall quality of the embossed checks.”

4. Showcase Your Communication and Teamwork Skills

Highlight your ability to communicate effectively with colleagues, clients, and superiors. Explain how you work as part of a team and contribute to a positive and collaborative work environment. Discuss your experience in resolving conflicts or addressing customer concerns.

- Example: “I am an effective communicator with excellent interpersonal skills. I am comfortable interacting with individuals at all levels of the organization. I am also a team player and enjoy collaborating with others to achieve common goals.”

5. Prepare Industry-Specific Questions

Research the specific industry or company you’re applying to. Prepare questions that demonstrate your interest in their business and your understanding of the current trends and challenges in the field. Asking thoughtful questions shows that you’re engaged, eager to learn, and genuinely interested in the role.

- Example: “I understand that your company recently implemented a new embossing technology. Could you share some insights into the benefits and challenges you’ve encountered with this new system?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Check Embosser interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.