Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Check Weigher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Check Weigher so you can tailor your answers to impress potential employers.

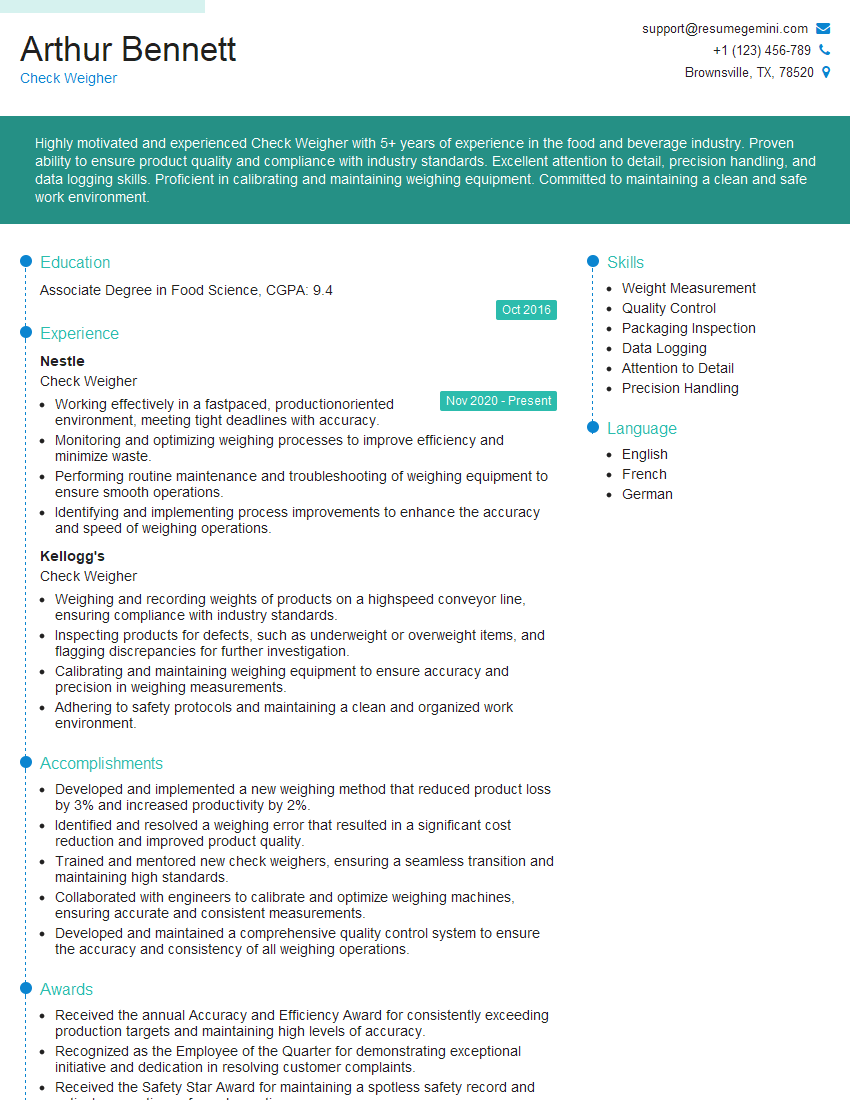

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Check Weigher

1. What is the purpose of a check weigher?

The purpose of a check weigher is to verify the weight of products as they move along a production line, ensuring that they meet specified weight requirements.

2. Explain the working principle of a check weigher.

A check weigher uses a load cell to measure the weight of a product. The product is placed on the weighing platform, and the load cell converts the weight into an electrical signal. This signal is then processed by the check weigher’s controller, which determines if the product meets the specified weight range.

3. What are the different types of check weighers available?

There are two main types of check weighers: in-motion check weighers and static check weighers. In-motion check weighers are used to weigh products that are moving along a conveyor belt, while static check weighers are used to weigh products that are stationary.

4. What are the key factors to consider when selecting a check weigher?

- The weight range of the products that need to be weighed

- The accuracy and precision requirements

- The speed of the production line

- The environmental conditions

5. How do you calibrate a check weigher?

Check weighers should be calibrated regularly to ensure accuracy. The calibration process involves using a known weight to verify the accuracy of the load cell. The check weigher’s controller is then adjusted to ensure that the weight readings are accurate.

6. What are the common problems that can occur with check weighers?

- Load cell failure

- Controller failure

- Conveyor belt problems

- Environmental factors (e.g., temperature, humidity)

7. How do you troubleshoot a check weigher?

Troubleshooting a check weigher involves identifying the source of the problem and taking appropriate corrective action. Some common troubleshooting steps include:

- Checking the load cell connections

- Checking the controller settings

- Inspecting the conveyor belt for damage

- Checking the environmental conditions

8. What is the importance of preventive maintenance for check weighers?

Preventive maintenance is important for check weighers to ensure that they continue to operate accurately and efficiently. Preventive maintenance tasks include:

- Regular calibration

- Cleaning and inspecting the load cell

- Inspecting the conveyor belt for damage

- Checking the environmental conditions

9. What are the safety precautions that should be taken when operating a check weigher?

- Never operate a check weigher without proper training

- Wear appropriate safety gear, such as gloves and safety glasses

- Keep the work area clean and free of debris

- Be aware of the potential for moving parts and pinch points

10. What are the future trends in check weigher technology?

Some of the future trends in check weigher technology include:

- Increased use of automation and robotics

- Improved accuracy and precision

- Development of new weighing technologies

- Integration with other quality control systems

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Check Weigher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Check Weigher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Check Weighers are responsible for ensuring that the weight of products meets the specified standards. They play a crucial role in maintaining product quality and preventing incorrect or insufficient packaging.

1. Product Weight Verification

Use weighing scales to accurately measure the weight of products.

- Compare measured weights against established standards.

- Identify and correct any discrepancies in weight.

2. Quality Control

Inspect products for defects, damage, or foreign objects.

- Ensure that products meet quality specifications.

- Reject or re-weigh products that do not meet standards.

3. Equipment Maintenance

Clean and calibrate weighing equipment regularly.

- Detect and report any equipment malfunctions.

- Adhere to safety regulations in the handling of equipment.

4. Data Recording

Maintain accurate records of product weights and inspection results.

- Generate reports and provide data for quality control purposes.

- Document any issues or corrective actions taken.

Interview Tips

Preparing for an interview for a Check Weigher position requires thorough knowledge of the job responsibilities and effective interviewing skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, values, and work environment.

- Review the job description and identify the key skills and experience required.

- Prepare specific examples of how your previous experience aligns with these requirements.

2. Quantify Your Results

When describing your previous experience, use specific numbers and metrics to demonstrate your impact.

- For instance, instead of saying “I checked product weights,” say “I weighed over 500 products per hour, ensuring 99.9% accuracy.”

3. Showcase Your Attention to Detail

Emphasize your ability to pay close attention to details and identify inconsistencies in product weights.

- Discuss any methods or techniques you have used to maintain accuracy and prevent errors.

4. Highlight Your Problem-Solving Abilities

Provide examples of how you have identified and resolved issues related to product weights or equipment.

- Describe the steps you took to diagnose the problem and implement effective solutions.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Check Weigher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Check Weigher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.