Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Checkering Machine Adjuster interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Checkering Machine Adjuster so you can tailor your answers to impress potential employers.

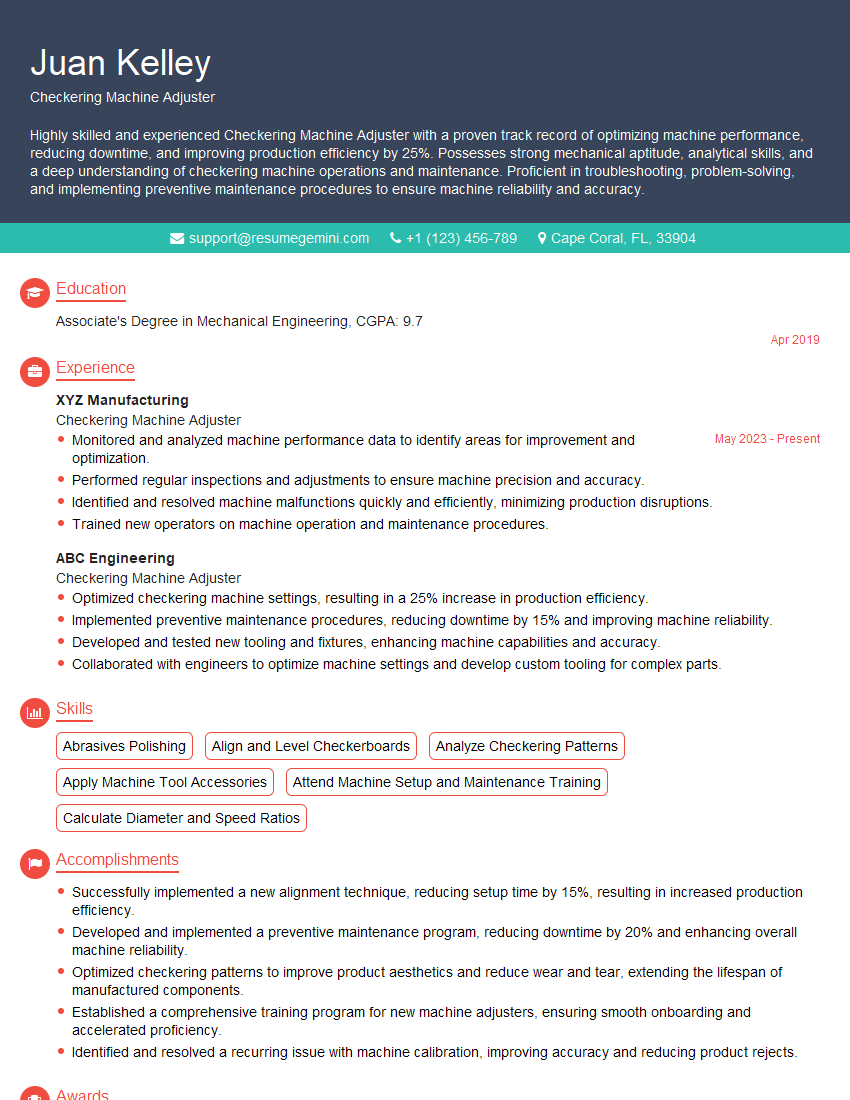

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Checkering Machine Adjuster

1. Describe the process of setting up a checkering machine.

- Inspect the machine and its components for any damage or wear.

- Mount the workpiece securely on the machine’s table.

- Select the appropriate checkering pattern and cutter.

- Adjust the machine’s settings, such as the cutting depth and feed rate.

- Test the machine’s operation by running a small test piece.

2. What are the different types of checkering patterns?

Raised patterns

- Diamond

- Point

- Basketweave

Impressed patterns

- Checkerboard

- Crosshatch

- Stippling

3. What factors affect the quality of a checkered surface?

- The sharpness of the cutter

- The cutting depth

- The feed rate

- The condition of the workpiece

- The skill of the operator

4. How do you troubleshoot a checkering machine?

- Check the machine’s power supply and fuses.

- Inspect the machine’s mechanical components for any damage or wear.

- Check the machine’s settings to ensure they are correct.

- Test the machine’s operation by running a small test piece.

- If the problem persists, consult the machine’s manual or contact the manufacturer.

5. What are the safety precautions that should be taken when operating a checkering machine?

- Always wear safety glasses and gloves.

- Keep the machine’s work area clean and free of debris.

- Never reach into the machine’s cutting area while it is in operation.

- Be aware of the machine’s moving parts.

- Follow the manufacturer’s instructions for operating the machine.

6. What is the difference between a single-action and a double-action checkering machine?

- Single-action machines use a single cutting stroke to create a checkering pattern.

- Double-action machines use two cutting strokes to create a checkering pattern, one to cut the outline of the pattern and the other to cut the depth of the pattern.

- Double-action machines are generally more accurate and produce a higher quality checkering pattern.

7. What is the purpose of a checkering jig?

- A checkering jig is a tool that is used to hold the workpiece in place while it is being checkered.

- Jigs help to ensure that the checkering pattern is evenly spaced and consistent.

- There are different types of jigs available for different types of workpieces and checkering patterns.

8. What is the best way to clean and maintain a checkering machine?

- Regularly clean the machine’s exterior surfaces with a damp cloth.

- Lubricate the machine’s moving parts according to the manufacturer’s instructions.

- Inspect the machine’s cutter regularly for wear and tear and replace it if necessary.

- Store the machine in a clean, dry place when not in use.

9. What is your experience with using different types of checkering machines?

- I have experience using both single-action and double-action checkering machines.

- I am familiar with the different types of cutters and jigs that are used with checkering machines.

- I have experience setting up, operating, and maintaining checkering machines.

10. What are your strengths and weaknesses as a checkering machine adjuster?

Strengths

- I am a skilled machinist with a strong understanding of the principles of checkering.

- I am able to set up, operate, and maintain checkering machines with precision and accuracy.

- I am a team player who is always willing to help others.

Weaknesses

- I am sometimes too detail-oriented, which can slow down my work.

- I am not always good at delegating tasks to others.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Checkering Machine Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Checkering Machine Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Checkering Machine Adjuster is responsible for setting up, operating, and maintaining checkering machines. These machines are used to create decorative patterns on the surface of wooden objects, such as gun stocks, furniture, and musical instruments.

1. Set up and Calibrate Machines

The Adjuster must first set up the machine by loading the workpiece into the machine and aligning the cutting tools. They must then calibrate the machine to ensure that the cutting tools are moving at the correct speed and depth.

2. Operate Machines

Once the machine is set up, the Adjuster operates the machine by using a series of levers and dials. They must monitor the machine closely to ensure that the cutting tools are producing the desired results.

3. Maintain Machines

The Adjuster is also responsible for maintaining the machine by cleaning and lubricating moving parts. They must also perform periodic inspections to identify any potential problems.

4. Troubleshoot and Repair Machines

If the machine breaks down, the Adjuster must troubleshoot and repair the machine. They may need to replace parts, adjust settings, or reprogram the machine.

Interview Tips

To ace your interview for a Checkering Machine Adjuster position, it is important to be prepared to answer questions about your experience and qualifications. You should also be able to demonstrate your knowledge of the checkering process and your ability to operate and maintain checkering machines.

1. Research the Company

Before your interview, take some time to research the company you are interviewing with. This will help you understand the company’s culture and values, as well as the specific requirements of the position.

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during your interview.

3. Bring a Portfolio of Your Work

If possible, bring a portfolio of your work to your interview. This will give the interviewer a chance to see your skills and experience firsthand.

4. Be Enthusiastic and Professional

Be sure to be enthusiastic and professional during your interview. This will make a positive impression on the interviewer and show them that you are interested in the position.

5. Ask Questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This will show the interviewer that you are engaged and interested in the opportunity.

Next Step:

Now that you’re armed with the knowledge of Checkering Machine Adjuster interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Checkering Machine Adjuster positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini