Are you gearing up for a career in Cheese Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cheese Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

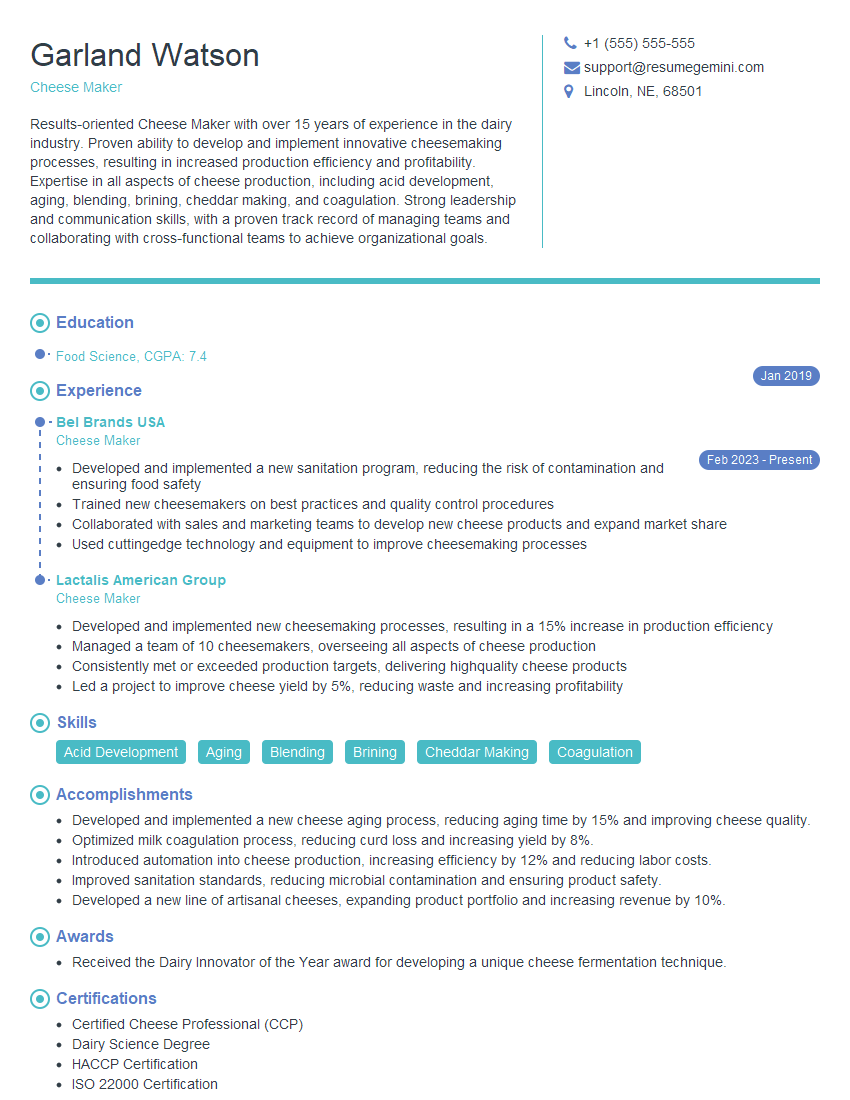

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cheese Maker

1. Describe the key steps involved in the cheesemaking process?

As a cheesemaker, I’ve mastered the art of transforming milk into delectable cheeses. The process involves several crucial steps:

- Milk Preparation: The journey begins with preparing the milk by standardizing its fat and protein content, ensuring consistent quality.

- Starter Culture Addition: I introduce carefully selected starter cultures to the milk, which convert lactose into lactic acid, initiating the acidification process.

- Rennet Coagulation: Rennet, a natural enzyme, is added to coagulate the milk proteins, forming a semi-solid curd.

- Cutting and Cooking the Curd: The curd is gently cut and heated to achieve the desired moisture and texture.

- Draining and Pressing: The whey is drained from the curd, which is then pressed into molds to shape and expel excess moisture.

- Aging and Ripening: The cheese is transferred to aging rooms, where it undergoes controlled temperature and humidity conditions to develop its unique flavors and textures.

- Packaging and Distribution: Once the cheese has reached its desired maturity, it is packaged and distributed to discerning consumers.

2. Explain the role of mesophilic and thermophilic bacteria in cheesemaking?

Mesophilic Bacteria

- Active at moderate temperatures (20-40°C)

- Used in the production of fresh cheeses, such as cottage cheese and soft cheeses

- Produce lactic acid, which acidifies the milk and contributes to the development of flavor

Thermophilic Bacteria

- Active at higher temperatures (40-60°C)

- Used in the production of semi-hard and hard cheeses, such as cheddar and mozzarella

- Produce lactic acid and also contribute to the breakdown of proteins and fats, resulting in more complex flavors and textures

3. Describe the different types of cheese cultures and their impact on cheese characteristics?

Cheese cultures play a vital role in determining the final characteristics of cheese. Here are some common types:

- Lactic Acid Bacteria (LAB): Primary cultures responsible for acid production, which affects the acidity and flavor of the cheese.

- Mesophilic LAB: Active at moderate temperatures, produce milder flavors and softer textures.

- Thermophilic LAB: Active at higher temperatures, produce more intense flavors and harder textures.

- Mold Cultures: Introduce molds to the cheese surface or interior, contributing to unique flavors and textures, such as in blue cheese and Brie.

- Yeast Cultures: Ferment lactose, producing carbon dioxide to create eyes in cheeses like Swiss and Emmental.

4. Explain the factors that influence the yield of cheese?

Several factors impact the yield of cheese, including:

- Milk Quality: Protein and fat content, as well as somatic cell count, affect the amount of cheese produced.

- Starter Culture Activity: The efficiency of the starter culture in converting lactose to lactic acid influences the moisture content and yield.

- Coagulation Process: The type of rennet used and the cutting and cooking techniques impact curd formation and moisture retention.

- Draining and Pressing: The duration and pressure applied during draining and pressing affect moisture loss and yield.

- Aging Conditions: Temperature and humidity during aging influence moisture loss and the development of cheese characteristics, which can affect the final yield.

5. Describe the techniques used to control the moisture content of cheese?

Controlling moisture content is crucial in cheesemaking. Techniques used include:

- Cutting and Cooking the Curd: The size of the curd particles and the temperature during cooking affect moisture retention.

- Draining and Pressing: The duration and pressure applied during these processes determine the amount of moisture removed.

- Salting: Salt draws moisture from the cheese, helping to control moisture content.

- Aging Conditions: Temperature and humidity during aging influence moisture loss and the development of cheese characteristics.

6. Explain the role of enzymes in cheesemaking and how they affect cheese quality?

Enzymes play a significant role in cheesemaking:

- Rennet: Coagulates milk proteins, forming the curd.

- Starter Culture Enzymes: Convert lactose to lactic acid, acidifying the milk and contributing to flavor development.

- Lipases: Break down fats, contributing to flavor and texture.

- Proteases: Break down proteins, influencing texture and flavor.

7. Describe the principles of HACCP as applied to cheesemaking?

HACCP (Hazard Analysis and Critical Control Points) principles ensure food safety in cheesemaking:

- Identify Hazards: Potential hazards throughout the process are identified.

- Establish Critical Control Points (CCPs): Points in the process where hazards can be controlled are identified.

- Set Critical Limits: Maximum or minimum values for each CCP to ensure safety.

- Monitor CCPs: Regular monitoring to ensure critical limits are met.

- Corrective Actions: Procedures to take if critical limits are exceeded.

- Verification: Regularly reviewing and validating the HACCP plan.

8. Explain the importance of sensory evaluation in cheesemaking?

Sensory evaluation is crucial for:

- Quality Control: Assessing cheese characteristics against established standards.

- Product Development: Evaluating new products or modifications.

- Consumer Feedback: Gathering insights on consumer preferences and acceptance.

- Process Optimization: Identifying areas for improvement in the cheesemaking process.

9. Describe the challenges and opportunities in the cheesemaking industry?

Challenges

- Fluctuating milk prices and availability

- Regulatory compliance and food safety standards

- Consumer demand for innovative and healthier cheese options

Opportunities

- Growing demand for artisanal and specialty cheeses

- Technological advancements in cheesemaking processes

- Collaboration with research institutions and universities

10. How do you stay updated on the latest advancements in cheesemaking techniques?

I’m committed to continuous learning and staying abreast of the latest advancements:

- Attending industry conferences and workshops

- Reading technical publications and scientific journals

- Participating in online forums and discussions

- Collaborating with fellow cheesemakers and experts

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cheese Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cheese Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cheesemakers are responsible for the production of cheese, a dairy product made from milk. They oversee the entire cheesemaking process, from the initial preparation of the milk to the final packaging and storage of the cheese.

1. Milk Preparation

Cheesemakers begin by preparing the milk for cheesemaking. This involves testing the milk for quality and composition, and then standardizing it to ensure that it has the correct fat content and acidity level. The milk is then heated to a specific temperature and rennet is added to cause it to coagulate.

- Test milk for quality and composition

- Standardize milk to ensure correct fat content and acidity level

- Heat milk to a specific temperature

- Add rennet to cause milk to coagulate

2. Curd Cutting and Forming

Once the milk has coagulated, the cheesemaker cuts the curd into small pieces. This allows the whey, the liquid portion of the milk, to be separated from the curds. The curds are then formed into blocks or wheels and pressed to remove additional whey.

- Cut curd into small pieces

- Separate whey from curds

- Form curds into blocks or wheels

- Press curds to remove additional whey

3. Salting and Aging

After pressing, the cheese is salted and aged. Salting helps to preserve the cheese and give it flavor. Aging allows the cheese to develop its characteristic texture and flavor. The length of time that the cheese is aged varies depending on the type of cheese being made.

- Salt cheese to preserve and flavor

- Age cheese to develop characteristic texture and flavor

- Monitor cheese during aging process

4. Packaging and Storage

Once the cheese has been aged, it is packaged and stored. Packaging helps to protect the cheese from contamination and spoilage. Storage conditions vary depending on the type of cheese being made.

- Package cheese to protect from contamination and spoilage

- Store cheese in appropriate conditions

- Monitor cheese during storage

Interview Tips

Preparing for an interview for a cheesemaker position can be daunting, but with the right preparation, you can ace the interview and land the job you want. Here are a few tips to help you prepare:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and the specific requirements of the job. You can find information about the company on their website, social media, and Glassdoor.

- Visit the company’s website and social media pages

- Read reviews of the company on Glassdoor

- Learn about the company’s history, culture, and values

2. Be prepared to talk about your experience

During your interview, you will likely be asked to talk about your experience in cheesemaking. Be prepared to discuss your skills and knowledge, and how you have used them to successfully produce cheese. You should also be able to talk about your experience with different types of cheese, and how you have adapted your techniques to produce each type.

- Discuss your skills and knowledge in cheesemaking

- Provide examples of how you have used your skills to successfully produce cheese

- Talk about your experience with different types of cheese

3. Be prepared to answer questions about the cheesemaking process

You may also be asked questions about the cheesemaking process. Be prepared to discuss the different steps involved in making cheese, and how you ensure that the cheese is of high quality. You should also be able to troubleshoot any problems that may arise during the cheesemaking process.

- Discuss the different steps involved in making cheese

- Explain how you ensure that the cheese is of high quality

- Troubleshoot any problems that may arise during the cheesemaking process

4. Be prepared to talk about your passion for cheesemaking

Cheesemaking is a demanding job, but it can also be very rewarding. Be prepared to talk about your passion for cheesemaking, and why you are interested in working for this company. You should also be able to articulate your goals for your career in cheesemaking.

- Discuss your passion for cheesemaking

- Explain why you are interested in working for this company

- Articulate your goals for your career in cheesemaking

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cheese Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!