Feeling lost in a sea of interview questions? Landed that dream interview for Cheese Processor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Cheese Processor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

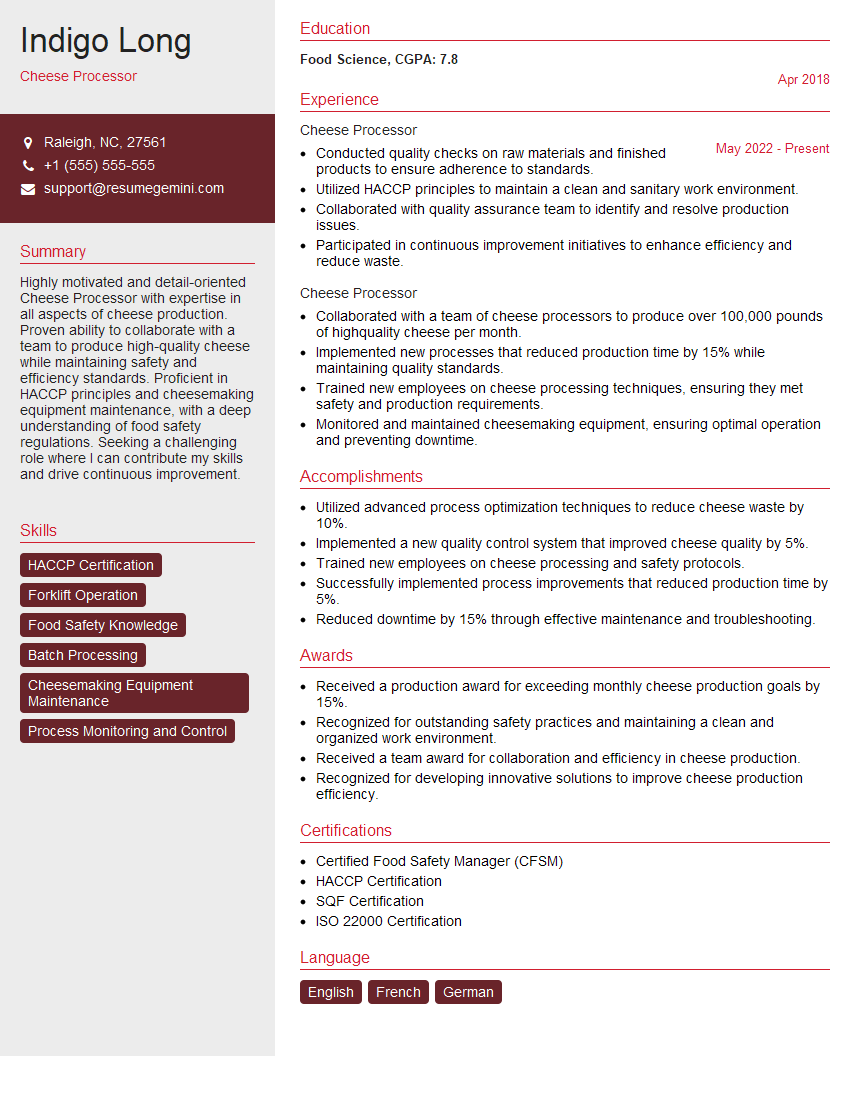

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cheese Processor

1. Describe the different types of cheese processing methods and their applications?

- Natural Cheesemaking: Uses starter cultures to convert lactose in milk into lactic acid, which lowers the pH and coagulates the milk proteins to form curds.

- Acid-Coagulated Cheesemaking: Adds acids (e.g., vinegar, lemon juice) to milk, causing the proteins to coagulate and form curds.

- Rennet-Coagulated Cheesemaking: Uses rennet, an enzyme extracted from animal stomachs, to coagulate the milk proteins and form curds.

- Ultrafiltration: Uses a membrane to separate milk into a low-protein whey and a high-protein retentate, which is then used to make cheese.

- Microfiltration: Similar to ultrafiltration, but uses a smaller membrane to remove bacteria and other microorganisms from milk.

2. Explain the role of starter cultures in cheese production?

Lactic Acid Production

- Starter cultures convert lactose in milk into lactic acid, lowering the pH.

- This acidification process helps coagulate milk proteins and form curds.

Flavor Development

- Starter cultures produce enzymes that break down proteins and fats in milk, creating flavor compounds.

- Different strains of starter cultures contribute to specific flavor profiles in different cheeses.

3. Describe the process of cheese ripening and its impact on flavor and texture?

Cheese ripening is a controlled process where cheese is stored under specific conditions to develop desired flavors and textures:

- Proteolysis: Enzymes break down proteins into smaller compounds, creating a softer texture and more complex flavors.

- Lipolysis: Enzymes break down fats into fatty acids, adding buttery or nutty flavors.

- Mold Growth: Certain cheeses are inoculated with molds to create distinctive flavors and textures (e.g., blue cheese).

- Bacterial Growth: Some cheeses develop characteristic flavors due to the growth of specific bacteria (e.g., washed-rind cheeses).

4. Explain the principles of cheese packaging and its importance for product quality?

- Barrier Properties: Packaging must protect cheese from oxygen, moisture, and light to prevent spoilage and preserve flavor.

- Gas Exchange: For cheeses that continue to ripen, packaging must allow for controlled gas exchange to maintain the desired atmosphere.

- Physical Protection: Packaging provides physical protection from damage during storage and transportation.

- Consumer Appeal: Packaging design and labeling can influence consumer perception and purchasing decisions.

5. Discuss the troubleshooting techniques for common cheesemaking defects?

- Acid Defects: Check starter culture activity, fermentation time, and pH levels.

- Body and Texture Defects: Adjust rennet dosage, cutting time, or cooking temperature.

- Flavor Defects: Identify potential contamination, starter culture selection, or ripening conditions.

- Eye Formation Defects: Ensure proper starter culture activity, cutting time, and piercing or gassing techniques.

6. Describe the safety and sanitation protocols required in a cheese processing facility?

- Good Manufacturing Practices (GMPs): Adherence to standardized practices for equipment cleaning, sanitation, and personnel hygiene.

- HACCP (Hazard Analysis and Critical Control Points): Identification and control of potential hazards in the production process.

- Food Safety Certifications: Compliance with relevant certifications (e.g., SQF, IFS) to ensure product safety.

- Regular Monitoring and Testing: Routine testing of сырье, in-process products, and finished products to prevent contamination.

7. Explain the quality control procedures for cheese production?

- Sensory Evaluation: Assessing cheese appearance, texture, flavor, and aroma.

- Chemical Analysis: Testing for pH, moisture, fat content, and other chemical parameters.

- Microbiological Testing: Determining the presence and levels of microorganisms to ensure safety.

- Process Monitoring: Tracking critical process parameters (e.g., temperature, time) to ensure consistent quality.

8. Describe the equipment used in cheese processing and their functions?

- Vat: Used for milk coagulation and curd formation.

- Curd Cutter: Cuts curds into desired size and shape.

- Cheese Press: Compacts curds to release whey and form cheese blocks.

- Ripening Room: Controlled environment for cheese aging.

9. Explain the factors that influence the yield of cheese from milk?

- Milk Composition: Fat and protein content of milk.

- Cheesemaking Process: Coagulation, cutting, and pressing techniques.

- Starter Culture Activity: Rate of acid production and curd formation.

- Moisture Content: Loss of whey during pressing and ripening.

10. Describe the regulatory requirements for cheese production and labeling?

- Food Safety Regulations: Compliance with federal and state food safety standards (e.g., FDA, USDA).

- Labeling Requirements: Accurate and informative labeling, including ingredients, nutritional information, and storage instructions.

- Certification and Licensing: Obtaining necessary certifications and licenses for cheese production and distribution.

- Traceability: Establishing systems to track сырье and finished products throughout the production process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cheese Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cheese Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Cheese Processor

A Cheese Processor plays a crucial role in a dairy production facility by executing a wide range of tasks related to cheese manufacturing and packaging. Key job responsibilities include:

1. Cheese Production and Processing

Operate and maintain equipment used in cheese production, such as coagulators, presses, and refrigeration systems.

- Monitor the cheese-making process to ensure compliance with quality standards.

- Adjust process parameters (e.g., temperature, acidity, culture addition) to optimize cheese yield and quality.

2. Packaging and Labeling

Prepare and package cheese according to customer specifications.

- Operate packaging machines (e.g., vacuum sealers, shrink wrappers) to ensure proper packaging and labeling.

- Inspect and verify that all necessary information (e.g., weight, expiration date, barcodes) is clearly printed.

3. Sanitation and Safety

Maintain a clean and sanitized work environment.

- Follow established sanitation protocols to prevent contamination and ensure product safety.

- Inspect equipment and work areas regularly to identify and address potential hazards.

4. Quality Assurance

Conduct inspections to monitor cheese quality.

- Sample and evaluate cheese for flavor, texture, and appearance.

- Identify and report any deviations from quality standards to supervisors.

Interview Tips to Ace the Cheese Processor Interview

Preparing for a Cheese Processor interview requires a combination of technical knowledge and soft skills. Here are some tips to help candidates succeed:

1. Understand the Job Description

Thoroughly review the job description to gain a clear understanding of the responsibilities and required qualifications.

- Highlight relevant experience and skills that align with the company’s needs.

- Research the cheese industry and specific cheese-making techniques to demonstrate your knowledge.

2. Practice Your Answers

Prepare answers to common interview questions, such as those related to your experience, skills, and motivation.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your accomplishments.

- Quantify your results whenever possible to demonstrate the impact of your work.

3. Highlight Your Teamwork and Communication Skills

Cheese processing is often a collaborative environment, requiring strong teamwork and communication skills.

- Describe situations where you effectively worked as part of a team to achieve a common goal.

- Emphasize your ability to communicate clearly and concisely, both verbally and in writing.

4. Demonstrate Your Passion for Cheese

Express your enthusiasm for cheese and cheese-making.

- Discuss your knowledge of different cheese varieties and production methods.

- Share any personal experiences or interests related to cheese, such as involvement in cheese clubs or attending industry events.

5. Prepare Relevant Questions

Asking thoughtful questions at the end of the interview shows your interest and engagement.

- Inquire about the company’s cheese-making process and quality standards.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cheese Processor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!