Are you gearing up for an interview for a Chemical Applicator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chemical Applicator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

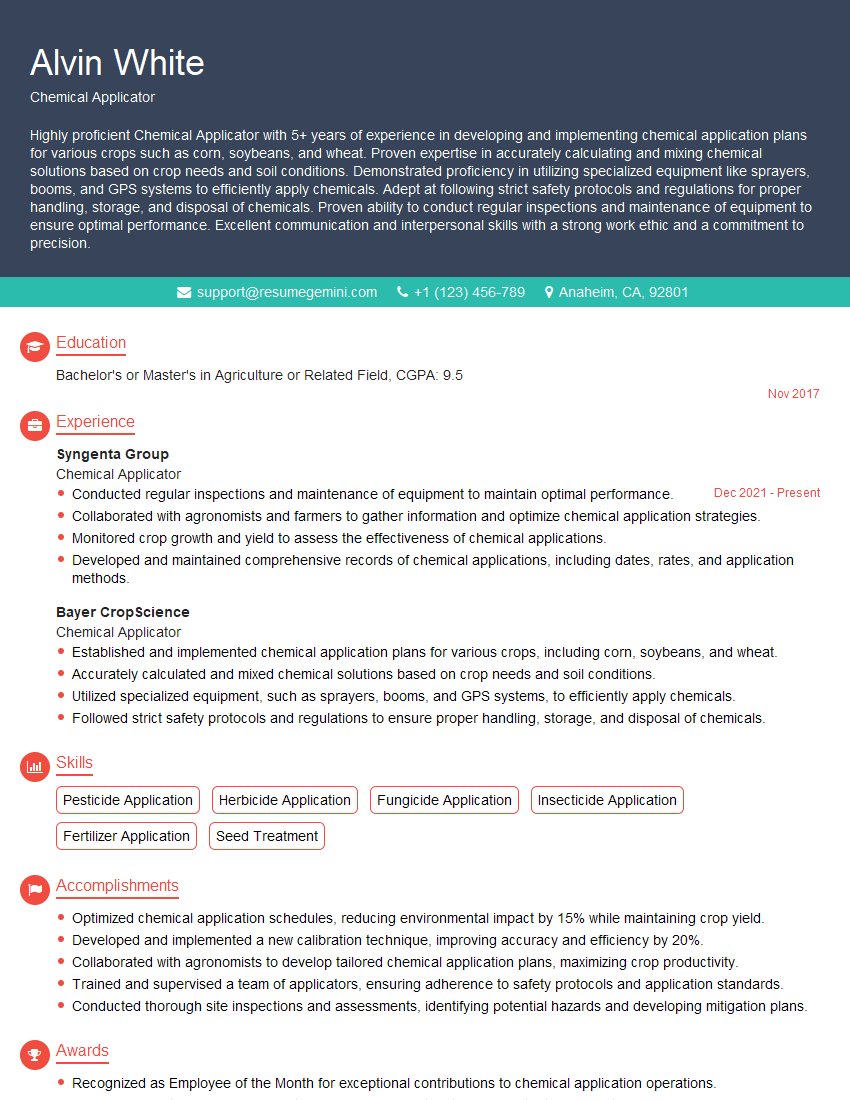

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Applicator

1. What are the different types of chemical application equipment?

There are several types of chemical application equipment used in the industry, including:

- Handheld sprayers: These are portable devices that use a pump to pressurize chemicals and spray them onto surfaces.

- Backpack sprayers: These are worn on the back and use a hand-operated pump to spray chemicals.

- Boom sprayers: These are mounted on vehicles and use a series of nozzles to spray chemicals over large areas.

- Airblast sprayers: These use a fan to create an airstream that carries the chemicals to the target area.

- Dusters: These apply chemicals in a dry powder form.

2. What are the key factors to consider when selecting the right chemical application equipment?

Equipment size and capacity:

- The size of the equipment should be appropriate for the area to be treated and the volume of chemicals to be applied.

Type of chemical being applied:

- Different chemicals require different types of application equipment. Some chemicals may be corrosive or require special handling.

Target area:

- The equipment should be suitable for the terrain and vegetation of the target area.

Environmental conditions:

- The equipment should be able to operate effectively in the expected environmental conditions, such as wind, temperature, and humidity.

3. How do you calibrate chemical application equipment?

Calibrating chemical application equipment is essential to ensure accurate application rates. The calibration process involves the following steps:

- Measuring the output of the equipment using a known volume of water.

- Adjusting the equipment’s settings to achieve the desired application rate.

- Verifying the calibration by applying a known amount of chemical to a test area and measuring the coverage.

4. What safety precautions should be taken when handling and applying chemicals?

When handling and applying chemicals, it is crucial to follow safety precautions to protect yourself and the environment. These precautions include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators.

- Following the manufacturer’s instructions for handling and mixing chemicals.

- Storing chemicals properly in a secure and well-ventilated area.

- Disposing of chemicals and their containers safely and according to regulations.

- Being aware of the potential hazards of the chemicals being used and taking appropriate measures to mitigate risks.

5. What are the common problems that can occur during chemical application and how do you troubleshoot them?

Like any equipment, chemical application equipment can experience issues. Some of the common problems and troubleshooting steps include:

- Clogged nozzles: This can be resolved by cleaning the nozzles with a solvent or using a nozzle cleaning tool.

- Leaking hoses or fittings: Tightening the connections or replacing the damaged parts can fix this.

- Pump failure: If the pump is not functioning, it may require repair or replacement.

- Incorrect application rate: Recalibrating the equipment and checking the settings can address this issue.

6. What are the different methods for applying chemicals to soil and crops?

There are several methods used to apply chemicals to soil and crops, each with its advantages and disadvantages:

- Broadcast spraying: This involves spraying chemicals over a wide area using boom sprayers or aircraft.

- Band spraying: Chemicals are applied in bands along the crop rows, reducing chemical usage and environmental impact.

- Foliar spraying: Chemicals are applied directly to the leaves of plants, targeting specific pests or diseases.

- Soil injection: Chemicals are injected directly into the soil, providing targeted application and reducing surface runoff.

- Seed treatment: Chemicals are applied to seeds before planting, protecting them from pests and diseases.

7. What are the factors that affect the efficacy of chemical application?

The effectiveness of chemical application can be influenced by several factors, including:

- Environmental conditions: Temperature, humidity, and wind can impact the evaporation and movement of chemicals.

- Plant growth stage: The stage of plant growth can affect the susceptibility to pests and diseases, influencing the timing and dosage of chemical application.

- Chemical formulation: The type of formulation, such as liquid, granular, or emulsifiable concentrate, can affect the application method and efficacy.

- Application timing: Applying chemicals at the right time, such as during peak pest activity or specific plant growth stages, is crucial for optimal results.

8. What are the environmental and regulatory considerations related to chemical application?

It is essential to consider environmental and regulatory aspects when applying chemicals:

- Environmental impact: Chemicals should be applied in a manner that minimizes harm to the environment, including water bodies, soil, and wildlife.

- Regulatory compliance: Adhering to local, state, and federal regulations governing chemical use, handling, and disposal is crucial.

- Worker safety: Ensuring the safety of those applying chemicals is paramount, which involves proper training, protective gear, and following safety protocols.

9. How do you stay up-to-date with the latest advancements in chemical application technology and best practices?

To stay current in the field, I engage in various activities:

- Attending industry conferences, workshops, and seminars provides opportunities to learn about new technologies and best practices.

- Reading trade publications, journals, and online resources keeps me informed about the latest research and developments.

- Seeking training and certification programs offered by manufacturers and industry organizations enhances my knowledge and skills.

10. What are your strengths and weaknesses as a Chemical Applicator?

As a Chemical Applicator, I possess several strengths that make me a valuable asset:

- Strong technical knowledge and understanding of chemical application principles and practices.

- Proficient in operating and maintaining various chemical application equipment, ensuring accurate and efficient application.

- Excellent attention to detail and a commitment to following safety protocols and regulatory guidelines.

- Ability to work independently and as part of a team, contributing to the overall success of chemical application projects.

While I am confident in my abilities, I recognize areas where I can continue to improve:

- Expanding my knowledge of emerging technologies and advancements in the field of chemical application.

- Seeking opportunities to enhance my communication and interpersonal skills for effective collaboration and information sharing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Applicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Applicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Applicators are responsible for applying chemicals to plants, crops, or soil to protect them from pests, diseases, and weeds. They must be knowledgeable about the chemicals they are using and the proper application methods.

1. Safety and Compliance

Chemical Applicators must follow all safety regulations and guidelines when handling and applying chemicals. They must wear proper protective gear, such as gloves, masks, and goggles, and must be aware of the potential hazards of the chemicals they are using.

- Follow all safety protocols and procedures

- Wear appropriate personal protective equipment (PPE)

- Inspect equipment regularly and maintain it in good working order

2. Chemical Application

Chemical Applicators must be able to accurately apply chemicals to plants, crops, or soil. They must be able to calibrate their equipment and apply the correct amount of chemical at the right time and in the right place. Chemical Applicators may also be required to mix and prepare chemicals.

- Calibrate and operate application equipment

- Mix and prepare chemicals according to specifications

- Apply chemicals to plants, crops, or soil using a variety of methods

3. Equipment Maintenance

Chemical Applicators are responsible for maintaining their equipment in good working order. They must be able to troubleshoot and repair minor problems, and must know when to call for professional help.

- Maintain and repair application equipment

- Lubricate, clean, and adjust equipment

- Troubleshoot and resolve equipment issues

4. Record Keeping

Chemical Applicators must keep accurate records of the chemicals they have applied, including the date, time, location, and amount of chemical applied. They must also keep records of any maintenance or repairs they have performed on their equipment.

- Maintain accurate records of chemical applications

- Document maintenance and repairs performed on equipment

- Keep records of training and certification

Interview Tips

To prepare for an interview for a Chemical Applicator position, you should:

1. Research the company and the position.

Familiarize yourself with the company’s website and social media pages to learn about their business, culture, and values. Also, be sure to read the job description carefully and identify the key responsibilities and qualifications for the position.

- Visit the company’s website and social media pages

- Read the job description carefully

- Identify the key responsibilities and qualifications for the position

2. Prepare your answers to common interview questions.

Some common interview questions for Chemical Applicators include:

- “Tell me about your experience in applying chemicals to plants, crops, or soil.”

- “What is your understanding of the safety regulations and guidelines for handling and applying chemicals?”

- “How do you calibrate and operate application equipment?”

You should prepare your answers to these questions in advance, and be sure to practice answering them out loud.

3. Dress professionally and arrive on time for your interview.

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as this shows that you are respectful of the interviewer’s time.

- Dress professionally

- Arrive on time for your interview

- Be polite and respectful to the interviewer

4. Be prepared to ask questions.

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Prepare questions to ask the interviewer

- This shows that you are interested in the position and the company

- It also gives you an opportunity to learn more about the company and the position

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Applicator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!