Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chemical Compounder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chemical Compounder so you can tailor your answers to impress potential employers.

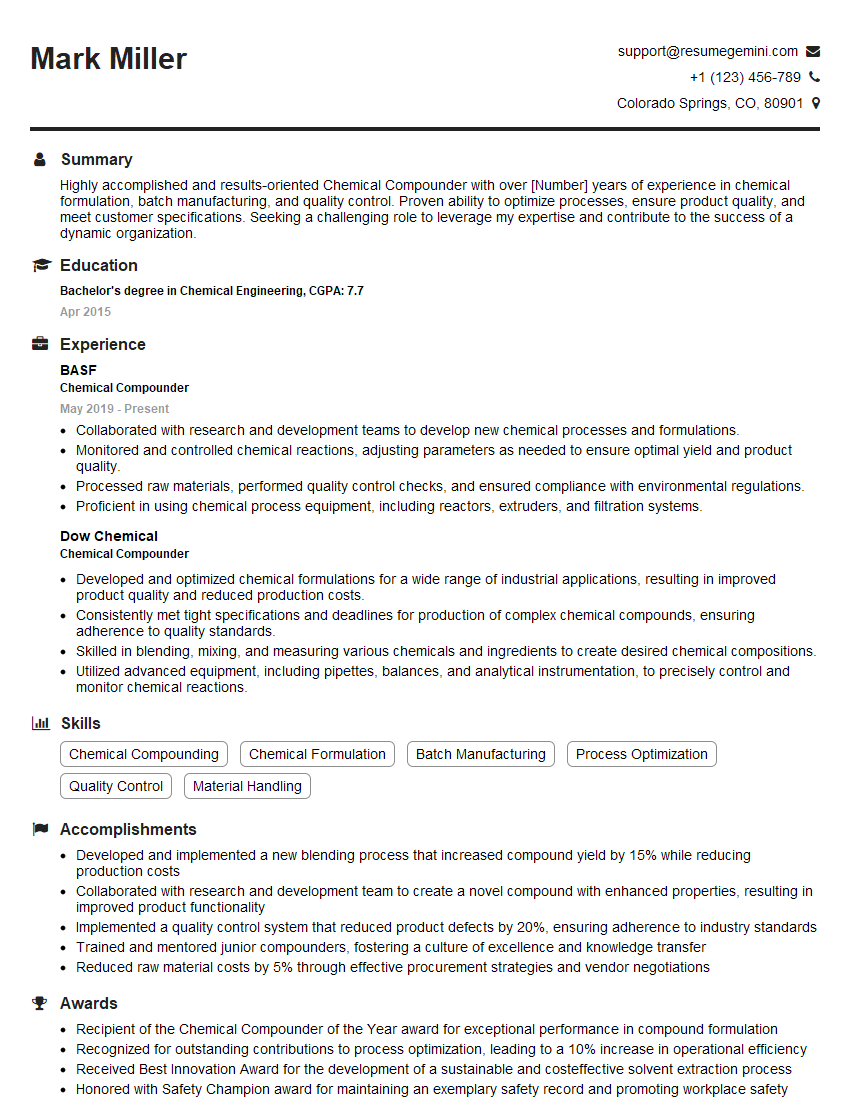

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Compounder

1. What are the key chemical compounds used in the production of plastics?

The key chemical compounds used in the production of plastics include:

- Ethylene

- Propylene

- Vinyl chloride

- Styrene

- Acetaldehyde

2. How do you ensure the accuracy and consistency of chemical formulations?

Quality Control Measures

- Regularly calibrate and maintain laboratory equipment.

- Follow standardized procedures for weighing, measuring, and mixing chemicals.

Documentation and Traceability

- Maintain accurate records of all raw materials and chemical formulations.

- Track the batch numbers and production dates to ensure traceability.

3. Describe the process of mixing and compounding chemical ingredients.

The process of mixing and compounding chemical ingredients involves:

- Accurately weighing and measuring each ingredient.

- Using specialized equipment, such as blenders or mixers, to combine the ingredients.

- Monitoring the mixing process to ensure homogeneity and consistency.

4. What safety precautions should be taken when handling hazardous chemicals?

When handling hazardous chemicals, it is crucial to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and a respirator.

- Handle chemicals in a well-ventilated area.

- Follow proper disposal procedures for hazardous waste.

5. How do you troubleshoot common problems encountered in chemical compounding?

To troubleshoot common problems encountered in chemical compounding, I follow a systematic approach:

- Identify the problem and its potential causes.

- Review the formulation and mixing process to identify any deviations.

- Adjust the formulation or process as necessary, based on my knowledge and experience.

- Monitor the results and make further adjustments if needed.

6. What are the different types of chemical reactions used in compounding?

In chemical compounding, several types of chemical reactions are commonly used:

- Addition reactions

- Condensation reactions

- Neutralization reactions

- Redox reactions

7. How do you calculate the stoichiometric ratios for a chemical reaction?

To calculate the stoichiometric ratios for a chemical reaction, I follow these steps:

- Write a balanced chemical equation for the reaction.

- Identify the mole ratios between the reactants and products.

- Use these mole ratios to determine the mass ratios of the reactants.

8. What equipment is commonly used in chemical compounding?

In chemical compounding, various equipment is commonly used, including:

- Blenders and mixers

- Reactors

- Centrifuges

- Filtration equipment

- Drying ovens

9. What are the quality control measures for chemical compounding?

To ensure the quality of chemical compounds, several quality control measures are implemented:

- Raw material inspection

- In-process testing

- Finished product testing

- Documentation and record-keeping

10. What are the environmental regulations related to chemical compounding?

Chemical compounders must comply with various environmental regulations, including:

- Clean Air Act

- Clean Water Act

- Resource Conservation and Recovery Act

- Toxic Substances Control Act

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Compounder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Compounder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Compounders are responsible for producing and testing various chemical compounds according to established procedures. Their primary duties include:

1. Production and Synthesis

Following specified formulations and procedures, they accurately measure and weigh ingredients, mix and blend compounds, and operate equipment to produce chemical products.

2. Quality Control and Testing

Chemical Compounders test and analyze raw materials and finished products to ensure compliance with quality standards. They use instruments and techniques like spectrophotometers, chromatographs, and titrations to conduct tests and monitor product properties.

3. Process Control and Optimization

They observe and monitor production processes to identify and resolve any issues or deviations. They work with production line operators to adjust parameters, troubleshoot problems, and optimize production yields.

4. Safety and Regulatory Compliance

Chemical Compounders adhere to safety protocols, follow industry standards, and maintain a clean and organized work environment. They comply with environmental regulations and hazardous waste disposal procedures.

Interview Tips

To ace the interview for a Chemical Compounder role, candidates should:

1. Research the Company and Industry

- Gather information about the company’s products, markets, and reputation.

- Stay up-to-date with industry trends, regulations, and technological advancements.

2. Prepare for Technical Questions

- Review basic chemistry concepts, chemical synthesis, and quality control techniques.

- Practice answering questions about your experience in production, testing, or process optimization.

3. Highlight Relevant Skills and Qualifications

- Emphasize your strong attention to detail, accuracy, and analytical thinking.

- Discuss your proficiency in handling chemicals, operating equipment, and interpreting test results.

4. Demonstrate Safety Consciousness

- Convey your understanding of safety protocols, hazardous materials handling, and waste disposal.

- Share examples of how you have maintained a safe and clean work environment in previous roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Compounder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.