Feeling lost in a sea of interview questions? Landed that dream interview for Chemical Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chemical Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

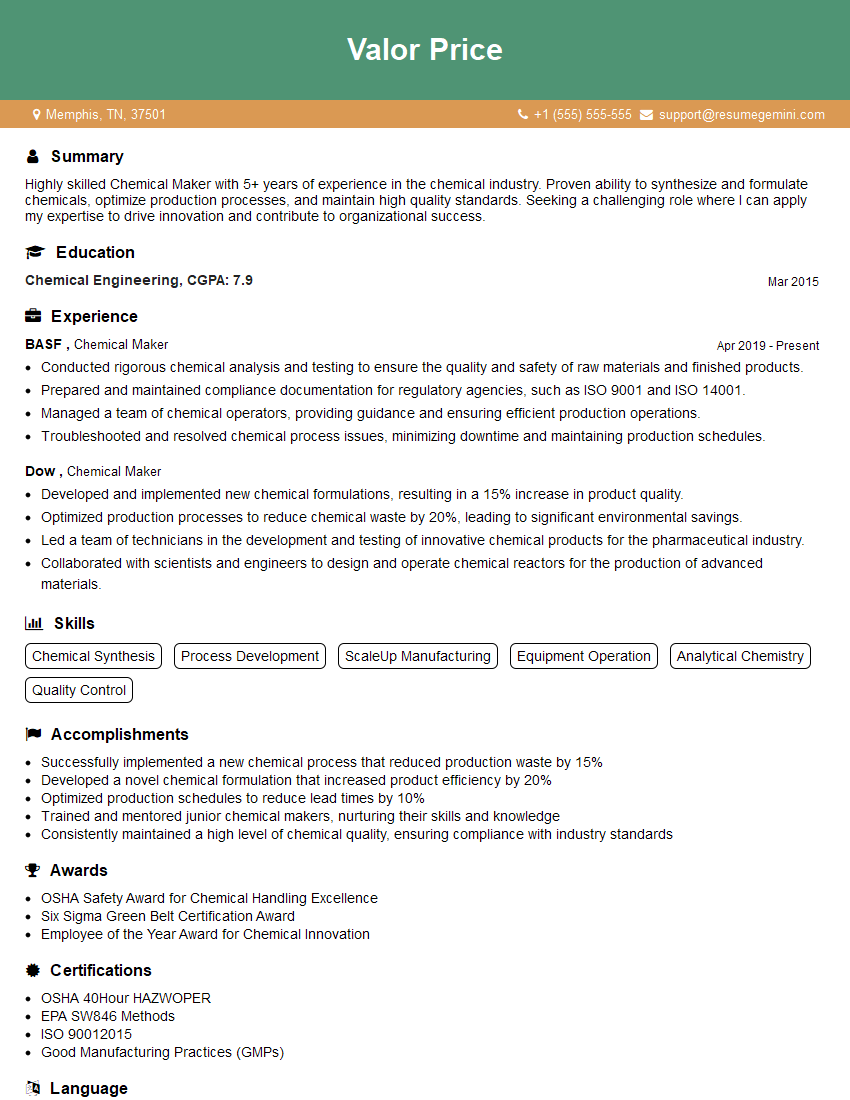

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Maker

1. Describe the process of creating a new chemical compound.

The process of creating a new chemical compound typically involves the following steps:

- Identifying a need or problem that a new chemical compound could solve.

- Researching the existing literature to identify potential starting materials and reaction pathways.

- Designing and conducting experiments to synthesize the new compound.

- Characterizing the new compound to determine its properties and behavior.

- Testing the new compound to evaluate its effectiveness in solving the identified need or problem.

2. What are the different types of chemical reactions?

Inorganic reactions

- Precipitation reactions

- Acid-base reactions

- Redox reactions

- Complexation reactions

Organic reactions

- Substitution reactions

- Addition reactions

- Elimination reactions

- Rearrangement reactions

3. What are the most important safety considerations when working with chemicals?

The most important safety considerations when working with chemicals include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a lab coat.

- Working in a well-ventilated area.

- Never eating or drinking in the laboratory.

- Always reading the Material Safety Data Sheet (MSDS) for any chemical before using it.

- Knowing the location of the nearest eyewash station and safety shower.

4. What are the different types of chemical analysis techniques?

The different types of chemical analysis techniques include:

- Spectroscopy

- Chromatography

- Electrochemistry

- Mass spectrometry

- Thermal analysis

5. What are the different types of chemical engineering unit operations?

The different types of chemical engineering unit operations include:

- Fluid flow

- Heat transfer

- Mass transfer

- Chemical reaction engineering

- Separation processes

6. What are the different types of chemical reactors?

The different types of chemical reactors include:

- Batch reactors

- Continuous reactors

- Plug flow reactors

- Mixed flow reactors

- Fluidized bed reactors

7. What are the different types of chemical separations processes?

The different types of chemical separations processes include:

- Distillation

- Extraction

- Crystallization

- Filtration

- Chromatography

8. What are the different types of chemical process control systems?

The different types of chemical process control systems include:

- Open-loop control systems

- Closed-loop control systems

- Proportional-integral-derivative (PID) controllers

- Model predictive controllers

- Fuzzy logic controllers

9. What are the different types of chemical plant equipment?

The different types of chemical plant equipment include:

- Tanks

- Pipelines

- Pumps

- Valves

- Heat exchangers

- Reactors

- Separators

10. What are the different types of chemical industry jobs?

The different types of chemical industry jobs include:

- Chemical engineers

- Chemical technicians

- Chemical operators

- Chemical sales representatives

- Chemical marketing managers

- Chemical research scientists

- Chemical plant managers

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Makers are responsible for the production of chemicals, typically in a manufacturing setting. They work with a variety of chemicals and equipment, and must have a strong understanding of chemistry and safety procedures.

1. Production

Chemical Makers are responsible for the production of chemicals according to specified formulas and procedures. They may operate a variety of equipment, including reactors, mixers, and distillation columns.

- Operate chemical production equipment, such as reactors, mixers, and distillation columns.

- Monitor production processes to ensure that they are running smoothly and efficiently.

- Make adjustments to production processes as needed to ensure that the desired product is produced.

2. Quality Control

Chemical Makers are responsible for ensuring that the chemicals they produce meet quality standards. They may conduct tests on raw materials and finished products to ensure that they meet specifications.

- Conduct quality control tests on raw materials and finished products.

- Identify and correct any problems that are found with the quality of the chemicals produced.

- Maintain records of quality control tests and results.

3. Safety

Chemical Makers must follow all safety procedures and regulations. They must be aware of the hazards associated with the chemicals they work with and must take precautions to protect themselves and others.

- Follow all safety procedures and regulations.

- Be aware of the hazards associated with the chemicals they work with.

- Take precautions to protect themselves and others from exposure to hazardous chemicals.

4. Maintenance

Chemical Makers may be responsible for maintaining the equipment they use. They may perform routine maintenance tasks, such as cleaning and lubricating equipment, and may also troubleshoot and repair problems.

- Perform routine maintenance tasks, such as cleaning and lubricating equipment.

- Troubleshoot and repair problems with equipment.

- Maintain records of maintenance activities.

Interview Tips

Preparing for an interview can be daunting, but it is important to remember that the interviewer is just another person. It is possible to make a great impression and land the job you want, even if you are nervous.

1. Research the Company and the Position

The first step in preparing for an interview is to research the company and the position you are applying for. Read the company website and LinkedIn profile, and read industry news. This information will give you a better understanding of the company’s culture, values, and goals.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Prepare Questions to Ask the Interviewer

Asking the interviewer questions is a great way to show that you are interested in the position and that you have done your research. It is also a good way to get more information about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What is the company’s culture like?”

4. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes, and avoiding clothing that is too revealing or casual. You should also arrive on time for your interview.

5. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest, be authentic, and be confident.

Next Step:

Now that you’re armed with the knowledge of Chemical Maker interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Chemical Maker positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini