Are you gearing up for an interview for a Chemical Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chemical Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

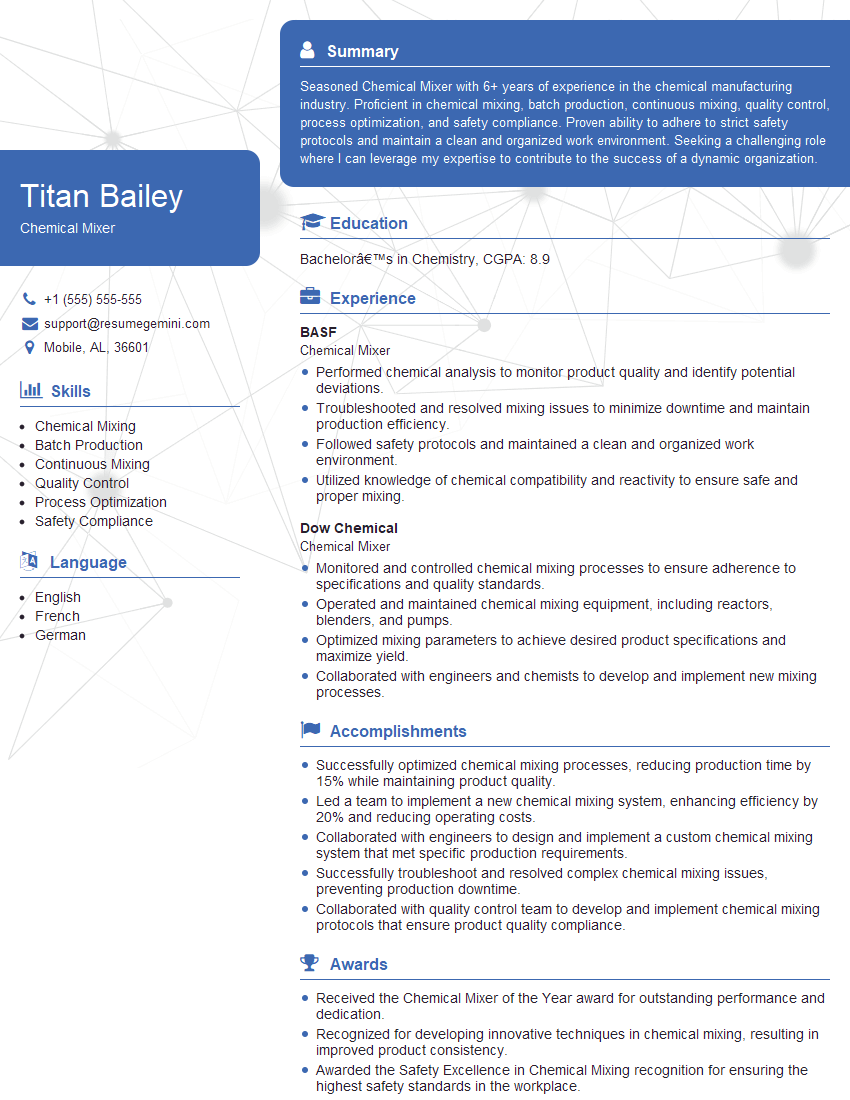

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Mixer

1. What are the key responsibilities of a Chemical Mixer?

- Operate and monitor chemical mixing equipment to ensure proper mixing of chemicals.

- Follow established procedures and safety protocols for handling and mixing chemicals.

- Maintain a clean and organized work area.

- Inspect and maintain equipment regularly to ensure optimal performance.

- Troubleshoot and resolve any issues that may arise during the mixing process.

2. What are the different types of chemical mixers?

Types of Chemical Mixers

- Batch mixers

- Continuous mixers

Batch Mixers

- Used for small-scale or intermittent mixing.

- Mix chemicals in a single batch.

Continuous Mixers

- Used for large-scale or continuous mixing.

- Mix chemicals as they flow through the equipment.

3. What are the factors to consider when selecting a chemical mixer?

- The type of chemicals being mixed.

- The desired mixing speed and intensity.

- The volume of chemicals to be mixed.

- The required level of precision and accuracy.

- The available space and budget.

4. What are the safety precautions that must be taken when working with chemical mixers?

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and a respirator.

- Handle chemicals according to their safety data sheets (SDSs).

- Ensure proper ventilation in the work area.

- Follow all established safety protocols and procedures.

5. What are some of the common problems that can occur with chemical mixers?

- Leaking or malfunctioning equipment.

- Improper mixing or contamination of chemicals.

- Electrical or mechanical failures.

6. What steps should be taken to troubleshoot and resolve problems with chemical mixers?

- Identify the problem and its potential causes.

- Refer to the equipment manual or consult with a qualified technician.

- Follow established troubleshooting procedures.

- Repair or replace any faulty components.

7. What are the maintenance requirements for chemical mixers?

- Regularly clean and inspect the equipment.

- Lubricate moving parts as needed.

- Calibrate and adjust the equipment according to manufacturer’s specifications.

- Replace worn or damaged components promptly.

8. What are the different types of mixing impellers?

Types of Mixing Impellers

- Propeller impellers

- Turbine impellers

- Paddle impellers

Propeller Impellers

- Used for low-viscosity fluids.

- Provide axial flow.

Turbine Impellers

- Used for medium- to high-viscosity fluids.

- Provide radial flow.

Paddle Impellers

- Used for gentle mixing or blending.

- Provide low shear forces.

9. What is the importance of proper mixing in chemical processes?

- Ensures uniform distribution of chemicals.

- Improves reaction efficiency and yield.

- Prevents segregation or settling of solids.

10. What are the latest advancements in chemical mixing technology?

- Computer-controlled mixing systems

- Advanced sensor technology for monitoring and control

- High-performance impellers and mixing vessels

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chemical Mixer plays a crucial role in the chemical manufacturing industry, ensuring the precise and safe blending of various chemical compounds. Their primary responsibilities include:

1. Mixing and Blending Chemicals

Using knowledge of chemical properties and formulations, Chemical Mixers operate mixing equipment to combine different chemical components in the correct ratios and concentrations.

- Follow pre-established formulas and recipes to blend chemicals accurately.

- Operate and maintain mixing equipment, ensuring it is functioning properly and efficiently.

2. Quality Control

Chemical Mixers are responsible for monitoring the quality of the mixed chemicals throughout the process.

- Conduct quality control tests to ensure the chemicals meet required specifications.

- Maintain records of all mixing operations, including the types and quantities of chemicals used.

3. Safety and Compliance

Working with potentially hazardous chemicals, Chemical Mixers must adhere to strict safety protocols and regulatory compliance.

- Follow established safety procedures when handling and mixing chemicals.

- Ensure that the mixing facility meets environmental and safety standards.

4. Troubleshooting and Maintenance

Chemical Mixers are expected to identify and resolve any issues that arise during the mixing process.

- Troubleshoot and resolve equipment malfunctions or process deviations.

- Perform routine maintenance and calibration of mixing equipment.

Interview Preparation Tips

Preparing for a Chemical Mixer interview requires a thorough understanding of the role and key competencies. Here are some valuable tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. This demonstrates your interest in the position and the company.

- Visit the company website and read about their operations and recent developments.

- Research the chemical manufacturing industry to gain insights into its challenges and opportunities.

2. Practice Your Technical Skills

Be prepared to discuss your knowledge of chemical mixing and quality control techniques.

- Review the basics of chemical properties, formulations, and safety protocols.

- Practice solving hypothetical problems related to chemical mixing and troubleshooting.

3. Emphasize Safety and Compliance

Highlight your commitment to following safety procedures and maintaining compliance with industry regulations.

- Share examples of your experience in handling hazardous chemicals and implementing safety measures.

- Explain your understanding of the relevant industry standards and regulations.

4. Prepare Questions for the Interviewer

Asking well-thought-out questions shows your engagement and interest in the role and the company.

- Inquire about the company’s current projects and future plans.

- Ask about the specific responsibilities and expectations of the Chemical Mixer position.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Chemical Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Chemical Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.