Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chemical Operations And Training position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

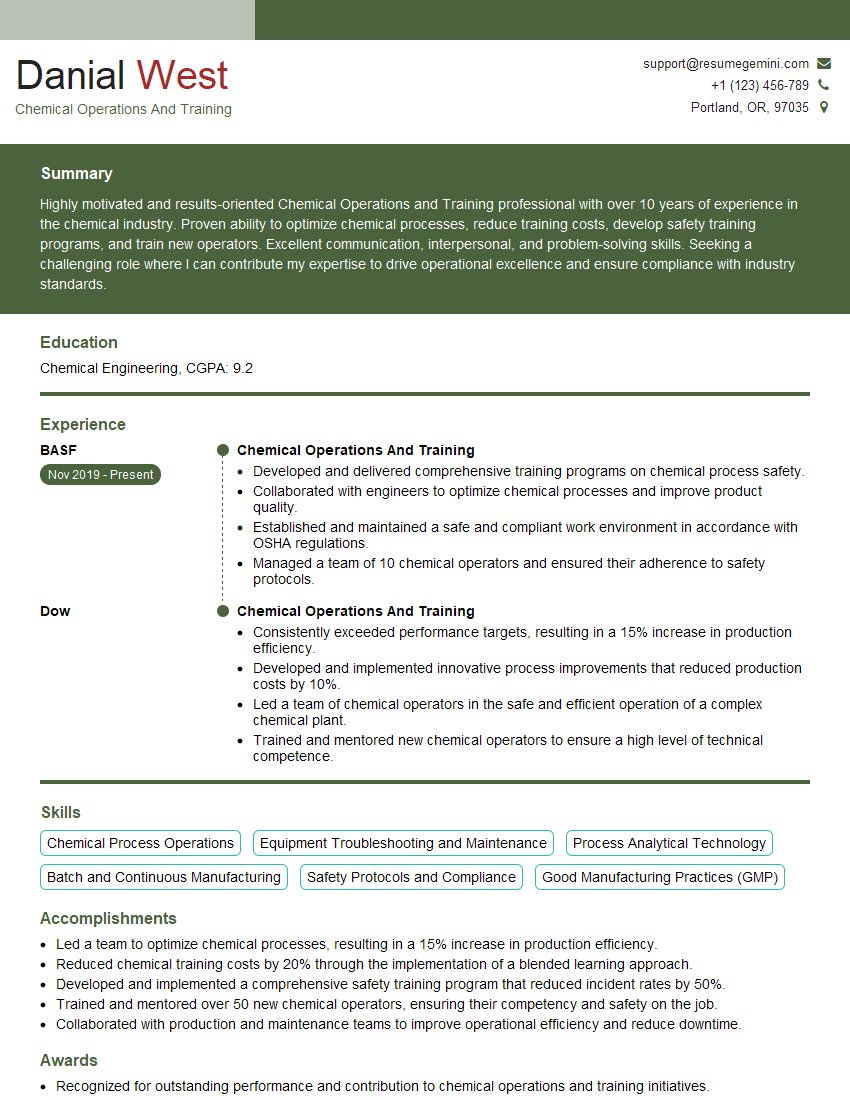

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Operations And Training

1. What are the key safety protocols you are familiar with in a chemical operations environment?

- Personal Protective Equipment (PPE) requirements, including respirators, gloves, and protective clothing

- Chemical handling procedures, including proper storage, transportation, and disposal

- Emergency response plans, including evacuation procedures and spill containment

- Work Permit Systems (WPS) and Job Safety Analysis (JSA) for high-risk activities

- Lockout/Tagout (LOTO) procedures for equipment maintenance and repairs

2. Describe the principles of chemical process control and how you would use them to optimize a production process?

Feedback Loop

- Monitor process variables (e.g., temperature, pressure, flow rate)

- Compare actual values to desired setpoints

Control Actions

- Adjust control variables (e.g., valve positions, pump speeds)

- Minimize deviations from setpoints

3. How would you approach troubleshooting a chemical process that is experiencing yield or quality issues?

- Gather data and review process parameters

- Identify potential root causes (e.g., equipment malfunction, raw material variations)

- Develop and implement corrective actions

- Monitor results and adjust troubleshooting plan as needed

4. What are the key principles of chemical laboratory safety?

- Proper handling and disposal of chemicals

- Appropriate use of personal protective equipment (PPE)

- Safe operation of laboratory equipment

- Emergency preparedness and response

- Good housekeeping and waste management

5. Describe the different types of chemical reactions and provide examples of each.

- Combination reactions: A + B → AB

- Decomposition reactions: AB → A + B

- Single-displacement reactions: A + BC → AC + B

- Double-displacement reactions: AB + CD → AD + CB

- Combustion reactions: Fuel + Oxidizer → Products (e.g., CO2, H2O)

6. What are the key factors that affect chemical reaction rates?

- Concentration of reactants

- Temperature

- Surface area of reactants

- Presence of a catalyst

7. Explain the concept of pH and its importance in chemical processes.

Definition: pH measures the acidity or alkalinity of a solution on a scale of 0 to 14.

Importance:

- Indicates the concentration of hydrogen ions in a solution

- Affects chemical reactions, such as corrosion and precipitation

- Crucial for biological processes, as many organisms have specific pH ranges

8. What are the different methods used for separating chemical mixtures?

- Filtration: Separates solids from liquids

- Distillation: Separates liquids based on boiling points

- Chromatography: Separates substances based on their chemical properties

- Extraction: Separates substances based on their solubility

9. Describe the role of chemical engineering in developing and designing chemical processes.

- Process design and optimization

- Equipment selection and design

- Process control and automation

- Safety and environmental considerations

- Project management

10. What are the key challenges and opportunities in the chemical industry?

Challenges:

- Environmental regulations

- Fluctuating raw material prices

- Increasing demand for sustainable technologies

Opportunities:

- Growth in emerging markets

- Advancements in biotechnology and materials science

- Development of renewable energy sources

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Operations And Training.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Operations And Training‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Chemical Operations and Training professional is responsible for overseeing the day-to-day operations of a manufacturing facility, as well as developing and implementing training programs for employees. Key job responsibilities include:

1. Operations Management

Managing all aspects of chemical operations, including production, quality control, safety, and environmental compliance.

- Developing and implementing production schedules

- Ensuring that all products meet quality standards

- Maintaining a safe and clean work environment

- Complying with all environmental regulations

2. Training and Development

Developing and implementing training programs for employees at all levels.

- Identifying training needs

- Developing training materials

- Delivering training programs

- Evaluating the effectiveness of training programs

3. Process Improvement

Continuously improving chemical operations through process improvement initiatives.

- Identifying areas for improvement

- Developing and implementing process improvement plans

- Monitoring the results of process improvement initiatives

- Making recommendations for further improvements

4. Team Leadership

Leading a team of employees responsible for chemical operations and training.

- Motivating and inspiring employees

- Providing feedback and coaching

- Resolving conflicts and issues

- Building a strong team culture

Interview Tips

Interview preparation is key to acing any interview, but it’s especially important for a role like Chemical Operations and Training, which requires a high level of technical expertise and leadership skills.

1. Research the Company and the Role

Take some time to learn about the company you’re interviewing with, as well as the specific role you’re applying for. This will help you understand the company’s culture, goals, and needs, and tailor your answers to the interviewer’s questions accordingly.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company, if possible

2. Practice Your Answers to Common Interview Questions

There are certain questions that are commonly asked in interviews for Chemical Operations and Training roles. By practicing your answers to these questions ahead of time, you’ll be able to deliver confident and articulate responses on the day of the interview.

- Tell me about your experience in chemical operations.

- What are your strengths and weaknesses as a leader?

- How do you stay up-to-date on the latest developments in chemical operations?

- What is your approach to training and development?

- What are your goals for this role?

3. Be Prepared to Talk About Your Technical Skills

As a Chemical Operations and Training professional, you’ll need to have a strong understanding of chemical processes, safety procedures, and quality control measures. Be prepared to discuss your technical skills and experience in detail during the interview.

- Highlight your knowledge of chemical engineering principles

- Describe your experience with process optimization and troubleshooting

- Discuss your understanding of safety regulations and compliance

- Showcase your ability to develop and implement training programs

4. Be Enthusiastic and Professional

First impressions matter, so it’s important to be enthusiastic and professional throughout the interview process. Dress appropriately, arrive on time for your interview, and be prepared to answer questions with confidence and poise.

- Smile and make eye contact with the interviewer

- Be polite and respectful

- Ask questions to show that you’re interested in the role

- Thank the interviewer for their time

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Operations And Training interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!