Feeling lost in a sea of interview questions? Landed that dream interview for Chemical Process Control, Design, or Development Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Chemical Process Control, Design, or Development Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

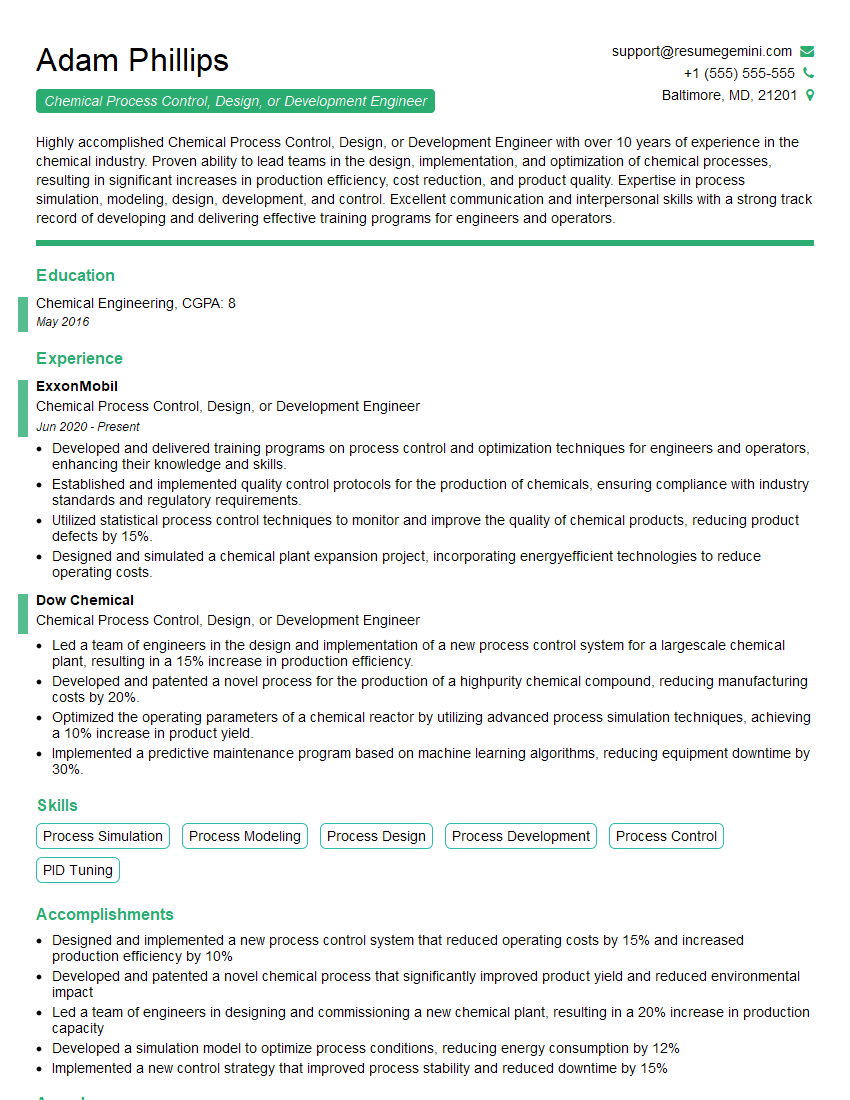

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Process Control, Design, or Development Engineer

1. How do you approach the design of a chemical process control system?

To approach the design, I follow these steps:

- Define the process objectives and constraints: Understand the desired outcomes and limitations of the process.

- Gather data and analyze the process: Collect and analyze relevant data to identify process variables, disturbances, and control requirements.

- Select and tune control loops: Choose and configure control loops to maintain process variables within desired ranges.

- Implement the control system: Integrate the control loops into the process and ensure proper operation.

- Monitor and optimize the system: Continuously monitor performance and make adjustments to optimize the control system’s efficiency.

2. Describe the principles and applications of PID control.

Proportional

- Applies a correction proportional to the error.

- Provides quick response but may lead to oscillations.

Integral

- Eliminates offset by calculating the sum of the error over time.

- Increases stability but can slow down response.

Derivative

- Predicts future error based on the rate of change of error.

- Improves stability and reduces overshoot, but can be sensitive to noise.

Applications:

- Temperature control

- Flow rate control

- Pressure control

3. Explain the concept of feedback control and its importance in chemical process control.

Feedback control involves monitoring the process output, comparing it to a desired setpoint, and using the error signal to adjust the process inputs. It ensures that the process output remains within desired limits by:

- Correcting deviations from the setpoint.

- Maintaining stability and preventing large fluctuations.

- Improving process efficiency and reducing waste.

- Enhancing safety by responding to disturbances and preventing process upsets.

4. Discuss the advantages and limitations of using model-based control techniques in chemical process design.

Advantages:

- Predicts process behavior and optimizes control strategies.

- Handles complex processes with multiple variables and interactions.

- Provides advanced control algorithms for improved performance.

Limitations:

- Relies on accurate process models, which may not always be available.

- Can be computationally intensive, especially for large-scale processes.

- May require specialized expertise for implementation and maintenance.

5. How do you evaluate the performance of a chemical process control system?

I evaluate performance based on key metrics:

- Stability: How well the process maintains desired setpoints.

- Accuracy: How closely the process output matches the setpoint.

- Response time: How quickly the process responds to changes in input.

- Efficiency: How well the process utilizes resources and minimizes waste.

- Safety: How effectively the control system prevents process upsets and ensures safe operation.

6. Explain the design considerations for a chemical process control system in a hazardous environment.

In hazardous environments, I consider:

- Intrinsic safety: Selecting equipment and components that are inherently safe and minimize the risk of explosions or fires.

- Redundancy: Implementing multiple layers of control to prevent single-point failures and ensure continuous operation.

- Isolation: Protecting the control system from hazardous areas using physical barriers and electrical isolation.

- Emergency shutdown systems: Designing systems that can quickly shut down the process in case of a hazardous event.

- Personnel safety: Ensuring that the control system is accessible and operable even during hazardous conditions.

7. Describe the role of artificial intelligence (AI) in modern chemical process control.

AI is increasingly used for:

- Predictive modeling: Using AI algorithms to predict process behavior and identify potential issues.

- Advanced control algorithms: Developing more sophisticated control strategies that optimize performance and handle complex dynamics.

- Fault detection and diagnosis: Detecting and diagnosing process faults in real-time, reducing downtime.

- Automated optimization: Continuously optimizing process parameters to maximize efficiency and productivity.

8. Discuss the ethical considerations in the design and implementation of chemical process control systems.

Ethical considerations include:

- Safety and reliability: Ensuring that the control system minimizes risks to human health and the environment.

- Data privacy and security: Protecting sensitive process data from unauthorized access or misuse.

- Environmental impact: Designing control systems that promote sustainable practices and minimize emissions.

- Transparency and accountability: Ensuring that the control system is transparent and auditable for regulatory compliance.

9. How do you stay updated with the latest advancements in chemical process control technology?

I stay updated through:

- Attending conferences and workshops: Network with experts and learn about new technologies and trends.

- Reading technical journals and articles: Stay informed about research and development in the field.

- Participating in online forums and discussion groups: Engage with peers and share knowledge.

- Taking continuing education courses: Expand my skills and learn about emerging technologies.

10. How do you approach troubleshooting a chemical process control system?

My troubleshooting approach involves:

- Gather information: Review process data, control system settings, and maintenance records.

- Identify the root cause: Analyze the information and identify potential causes of the issue.

- Develop a solution: Evaluate possible solutions and select the most appropriate one.

- Implement the solution: Make necessary adjustments to the control system or process.

- Monitor and verify: Track the system’s performance to ensure the issue has been resolved.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Process Control, Design, or Development Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Process Control, Design, or Development Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Chemical Process Control, Design, or Development Engineer, an individual will be entrusted with an array of critical responsibilities pertaining to the design, development, and control of chemical processes. These responsibilities encompass a broad spectrum of activities, from conceptualizing new processes to troubleshooting existing ones.

1. Process Design and Development

This aspect involves designing new chemical processes or modifying existing ones to enhance efficiency, yield, and product quality. Engineers in this role employ their expertise in chemical engineering principles and software tools to optimize process parameters and equipment selection.

- Conduct feasibility studies and conceptual designs for new processes.

- Develop process flow diagrams, piping and instrumentation diagrams, and equipment specifications.

2. Process Control and Optimization

Engineers are responsible for implementing and maintaining control systems to ensure that chemical processes operate within desired parameters. They monitor process variables such as temperature, pressure, and flow rate, and make adjustments to maintain stability and efficiency.

- Design and implement control strategies using process control software and hardware.

- Troubleshoot process control issues and make necessary adjustments to improve performance.

3. Process Safety and Compliance

Chemical Process Control, Design, or Development Engineers play a vital role in ensuring the safety and compliance of chemical processes. They are responsible for identifying and mitigating potential hazards and ensuring that processes adhere to regulatory requirements.

- Conduct risk assessments and develop safety protocols for chemical processes.

- Ensure compliance with environmental regulations and industry standards.

4. Research and Innovation

These engineers are often involved in research and development activities to improve existing processes or develop new technologies. They may collaborate with scientists, researchers, and academics to explore novel ideas and solutions.

- Conduct research to identify process improvements and develop new technologies.

- Collaborate with cross-functional teams to develop innovative solutions for chemical processes.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help candidates ace their interview for a Chemical Process Control, Design, or Development Engineer position:

1. Research the Company and Industry

Take the time to research the company and the chemical industry to demonstrate your interest and knowledge. Learn about their products, processes, and current projects to tailor your answers to the specific requirements of the role.

- Visit the company’s website and read industry news articles.

- Identify the company’s competitors and market trends.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in chemical engineering, process control, and design. Showcase your experience in software tools, such as process simulators and control systems. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of projects where you have successfully designed, implemented, or optimized chemical processes.

- Highlight your ability to work independently and as part of a team.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to chemical process control, design, and development. These questions may cover topics such as process modeling, control strategies, and safety considerations. Practice answering these questions clearly and concisely.

- Review basic chemical engineering principles and equations.

- Familiarize yourself with common process control techniques and software.

4. Show Your Passion and Enthusiasm

Convey your passion for chemical engineering and your interest in the position. Share your career goals and explain how this role aligns with your aspirations. Demonstrating your enthusiasm will help you stand out from other candidates.

- Discuss your motivation for pursuing a career in chemical engineering.

- Express your interest in the specific industry or company where you are interviewing.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Process Control, Design, or Development Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!