Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Chemical Process Engineer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

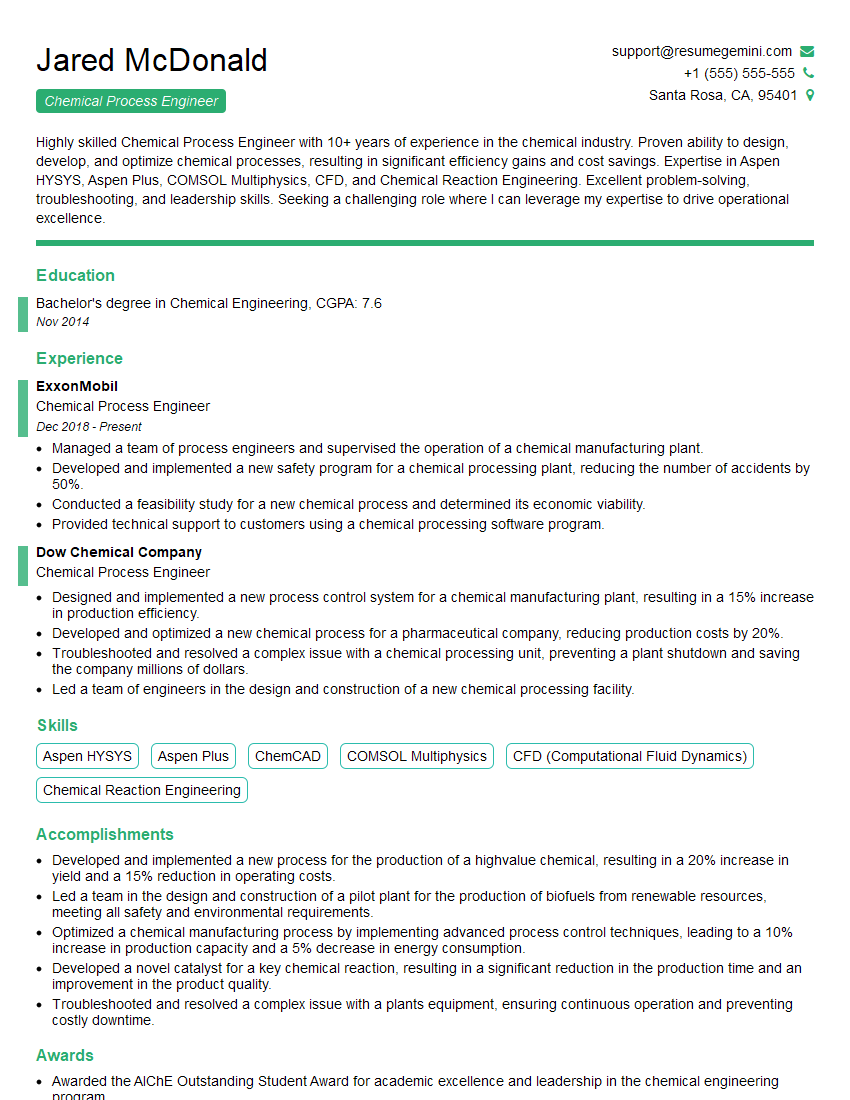

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Process Engineer

1. How do you determine the residence time distribution (RTD) of a chemical reactor?

To determine the RTD of a chemical reactor, I would use one of the following methods:

- Tracer experiment: Inject a tracer into the reactor and measure its concentration at the outlet as a function of time. The RTD can be obtained from the resulting breakthrough curve using appropriate mathematical analysis.

- Computational fluid dynamics (CFD) simulation: Utilize CFD software to simulate the flow and transport of fluid within the reactor. The RTD can be calculated based on the simulated velocity and concentration profiles.

- Method of moments: Apply statistical techniques to analyze the reactor’s input and output signals (e.g., temperature, concentration) and derive the RTD from the calculated moments.

2. Explain the concept of chemical equilibrium and its significance in process design.

Thermodynamic Perspective

- Chemical equilibrium is a state in which the forward and reverse reactions occur at equal rates, resulting in no net change in concentrations.

- It is determined by the Gibbs free energy minimization principle, where the system seeks the lowest energy state.

Process Design Significance

- Predicting product yields and compositions in chemical reactions.

- Optimizing reactor design and operating conditions for desired product selectivity.

- Understanding the impact of temperature, pressure, and other process variables on reaction equilibrium.

3. How do you approach the design of a packed bed reactor?

The design of a packed bed reactor involves the following steps:

- Determining reactor volume: Calculate the required reactor volume based on the reaction kinetics, desired conversion, and flow rate.

- Selecting packing material: Choose a packing material with appropriate surface area, porosity, and chemical compatibility.

- Pressure drop calculations: Estimate the pressure drop across the reactor bed using empirical correlations or CFD simulations.

- Fluid flow distribution: Analyze the flow distribution within the reactor to ensure uniform contact between reactants and packing.

- Heat transfer analysis: Consider the heat transfer requirements and design cooling or heating systems as needed.

4. Describe the principles of heat exchanger design and the factors considered during selection.

Heat exchanger design involves several key principles:

- Heat transfer rate: Calculate the heat transfer rate based on the heat transfer coefficient, surface area, and temperature difference.

- Pressure drop: Determine the pressure drop across the heat exchanger due to fluid flow resistance.

- Fouling and corrosion resistance: Select materials that resist fouling and corrosion in the operating environment.

- Fluid properties (temperature, viscosity, fouling potential)

- Heat transfer requirements

- Pressure drop constraints

- Cost and maintenance considerations

Selection Factors

5. What are the key considerations for the design and operation of a distillation column?

Distillation column design and operation involve several key considerations:

- Mass and energy balances: Perform mass and energy balances to determine the required column dimensions and operating conditions.

- Vapor-liquid equilibrium (VLE) data: Utilize VLE data to design the column trays or packing to achieve the desired separation.

- Column internals: Select appropriate trays or packing to promote efficient contact between the vapor and liquid phases.

- Reboiler and condenser design: Design the reboiler and condenser to provide the necessary heat transfer for vaporization and condensation.

- Process control and optimization: Implement control strategies to maintain stable operation and optimize product purity and recovery.

6. Explain the concept of process simulation and its applications in chemical engineering.

Process simulation involves developing mathematical models to represent chemical processes and predict their behavior under various operating conditions.

- Applications:

- Process design and optimization

- Troubleshooting and debottlenecking

- Training and operator guidance

- Safety and environmental analysis

7. How do you assess the safety hazards associated with a chemical process?

Assessing safety hazards in a chemical process involves the following steps:

- Hazard identification: Identify potential hazards based on the materials used, process conditions, and equipment involved.

- Risk assessment: Evaluate the likelihood and severity of each hazard using qualitative or quantitative methods.

- Hazard mitigation: Implement safety measures such as engineering controls, administrative procedures, and personal protective equipment to minimize risks.

- Emergency response planning: Develop plans to respond effectively to potential incidents and minimize their impact.

8. Describe the principles of chemical reaction kinetics and their application in process design.

Reaction Rate Laws

- Mathematical expressions that describe the rate of change of reactant or product concentrations over time.

- Involve reaction orders, rate constants, and temperature dependence.

Applications in Process Design

- Predicting reaction rates and product yields

- Optimizing reactor design and operating conditions

- Developing kinetic models for process simulation

9. Explain the role of computational fluid dynamics (CFD) in chemical process design.

CFD involves solving the governing equations of fluid flow and heat transfer using numerical methods.

- Applications:

- Analyzing fluid flow patterns and pressure drops

- Predicting heat transfer rates and temperature distributions

- Optimizing reactor and heat exchanger designs

- Simulating complex chemical processes

10. Describe the process of developing a control strategy for a chemical plant.

- Process analysis: Understand the process dynamics and identify key control variables.

- Control objective definition: Specify the desired performance outcomes, such as product quality, stability, and efficiency.

- Controller selection: Choose appropriate control algorithms (e.g., PID, MPC) based on process characteristics and control objectives.

- Loop tuning: Adjust controller parameters to achieve optimal control performance.

- Implementation and monitoring: Implement the control strategy and monitor its effectiveness. Fine-tune as necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Process Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Process Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Process Engineers are responsible for the design, operation, and optimization of chemical processes and plants. Their primary goal is to ensure that these processes are efficient, safe, and environmentally friendly.

1. Process Design and Development

Design and develop new chemical processes or modify existing ones to meet specific production requirements.

- Conduct feasibility studies to evaluate the technical and economic viability of new processes.

- Create process flow diagrams, equipment specifications, and control systems.

2. Process Simulation and Modeling

Utilize computer simulation software to model and optimize chemical processes before implementation.

- Develop mathematical models to predict process behavior and identify potential bottlenecks.

- Analyze simulation results to determine optimal operating conditions and equipment sizing.

3. Process Operation and Control

Monitor and control chemical processes to ensure they operate efficiently and safely.

- Develop and implement control strategies to maintain process variables within desired ranges.

- Troubleshoot and resolve process problems to minimize downtime and ensure production targets are met.

4. Process Optimization

Continuously evaluate and improve chemical processes to increase efficiency and reduce operating costs.

- Propose process modifications to improve yield, reduce energy consumption, or enhance safety.

- Conduct pilot-scale experiments to validate new process designs and operating procedures.

Interview Tips

Preparing thoroughly for a job interview is crucial to increasing your chances of success. Here are some tips to help you ace your interview for a Chemical Process Engineer position:

1. Research the Company and Position

Learn about the company’s culture, values, and the specific role you are applying for. This knowledge will demonstrate your interest in the opportunity and help you align your responses to the company’s needs.

2. Practice Your Technical Skills

Chemical Process Engineering is a technical field, so be prepared to answer questions related to your technical abilities. Review your knowledge of process design, simulation, control, and optimization techniques.

3. Highlight Your Communication Skills

Chemical Process Engineers often work in collaborative environments and must be able to communicate effectively with engineers, operators, and management personnel. Showcase your ability to convey technical information clearly and persuasively.

4. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your problem-solving, teamwork, and leadership abilities. Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide specific examples of your experiences.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Chemical Process Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.