Are you gearing up for an interview for a Chemical Process Equipment Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chemical Process Equipment Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

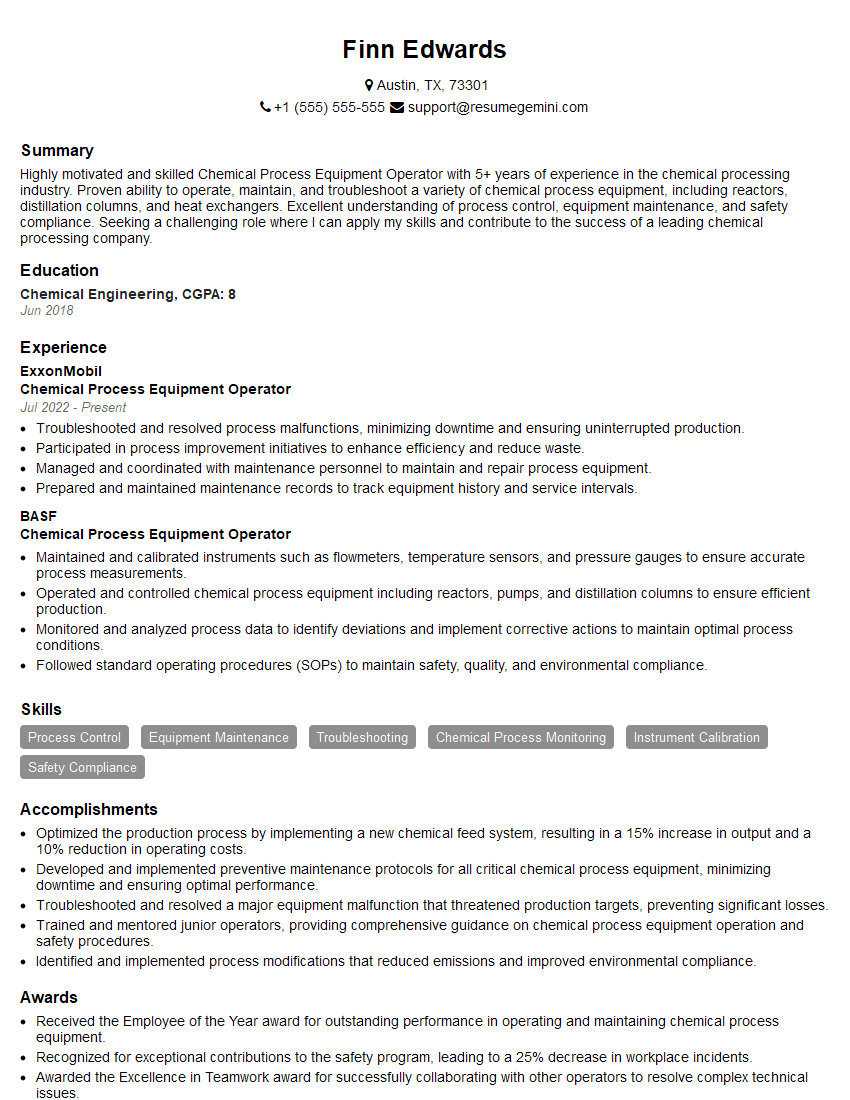

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Process Equipment Operator

1. Explain the working principle of a centrifugal pump?

A centrifugal pump is a device that converts mechanical energy into kinetic energy, which is then transferred to a fluid. The basic principle of operation is that a rotating impeller imparts velocity to the fluid, which is then converted to pressure energy. The impeller is mounted on a shaft that is driven by a motor or engine. As the impeller rotates, it creates a centrifugal force that pushes the fluid outward from the center of the pump. The fluid is then discharged through the outlet of the pump.

- The centrifugal force is proportional to the square of the impeller speed.

- The discharge pressure is proportional to the square of the impeller diameter.

- The flow rate is proportional to the impeller speed and the impeller diameter.

2. What are the different types of heat exchangers?

Shell and Tube Heat Exchangers

- Consists of a bundle of tubes enclosed in a cylindrical shell.

- One fluid flows through the tubes, while the other fluid flows through the shell.

- The tubes are typically made of metal, while the shell can be made of metal, plastic, or glass.

Plate and Frame Heat Exchangers

- Consists of a series of corrugated plates that are clamped together.

- The fluid flows through the channels formed between the plates.

- The plates are typically made of stainless steel or titanium.

Air Cooled Heat Exchangers

- Consists of a series of tubes that are cooled by air.

- The fluid flows through the tubes, while the air flows over the tubes.

- The tubes are typically made of aluminum or copper.

3. What are the common problems associated with pumps?

- Cavitation: This occurs when the pressure in the pump inlet drops below the vapor pressure of the fluid, causing the fluid to vaporize. This can lead to noise, vibration, and damage to the pump.

- Overheating: This can be caused by a number of factors, including excessive friction, inadequate lubrication, or a blocked cooling system.

- Bearing failure: This can be caused by a number of factors, including excessive wear, contamination, or misalignment.

- Seal failure: This can allow fluid to leak from the pump, leading to a loss of efficiency and potential environmental hazards.

- Corrosion: This can be caused by a number of factors, including exposure to corrosive fluids, acids, or bases.

4. What are the different types of valves used in chemical process equipment?

- Gate valves: These valves are used to isolate a section of pipe from the rest of the system. They are typically used in applications where a high degree of shutoff is required.

- Globe valves: These valves are used to regulate the flow of fluid in a pipe. They are typically used in applications where a gradual change in flow rate is required.

- Check valves: These valves are used to prevent the backflow of fluid in a pipe. They are typically used in applications where a one-way flow of fluid is required.

- Ball valves: These valves are used to isolate a section of pipe from the rest of the system. They are typically used in applications where a quick and easy shutoff is required.

- Diaphragm valves: These valves are used to regulate the flow of fluid in a pipe. They are typically used in applications where a high degree of leak tightness is required.

5. What are the safety precautions that must be taken when working with chemical process equipment?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Be aware of the hazards associated with the chemicals being used.

- Follow all safety procedures and protocols.

- Do not operate equipment that you are not trained to use.

- Report any spills or accidents immediately.

6. What are the different types of chemical process equipment?

- Vessels: These are used to hold and store chemicals and other materials. They can be made of a variety of materials, such as stainless steel, glass, and plastic.

- Pumps: These are used to move fluids from one location to another. They can be positive displacement pumps or centrifugal pumps.

- Heat exchangers: These are used to transfer heat from one fluid to another. They can be shell and tube heat exchangers, plate and frame heat exchangers, or air cooled heat exchangers.

- Valves: These are used to control the flow of fluids in a system. They can be gate valves, globe valves, check valves, ball valves, or diaphragm valves.

- Piping: This is used to connect the different pieces of equipment in a system. It can be made of a variety of materials, such as stainless steel, plastic, and glass.

7. What is the role of a chemical process equipment operator?

- Operate and maintain chemical process equipment.

- Monitor process parameters and make adjustments as needed.

- Troubleshoot and repair equipment problems.

- Follow safety procedures and protocols.

- Keep accurate records of process data.

8. What are the qualifications for a chemical process equipment operator?

- High school diploma or equivalent.

- 1-2 years of experience in a related field.

- Strong knowledge of chemical process equipment.

- Ability to operate and maintain equipment safely.

- Ability to troubleshoot and repair equipment problems.

- Ability to follow safety procedures and protocols.

- Ability to keep accurate records of process data.

9. What is the work environment of a chemical process equipment operator?

- Chemical process equipment operators typically work in industrial settings, such as chemical plants, refineries, and pharmaceutical plants.

- They may work in a variety of environments, including indoor and outdoor, and may be exposed to hazardous chemicals and other materials.

- They may work long hours, including overtime and weekends, and may be required to work in shifts.

10. What is the career outlook for a chemical process equipment operator?

- The job outlook for chemical process equipment operators is expected to be good over the next few years.

- This is due to the increasing demand for chemicals and other products manufactured by the chemical process industry.

- Chemical process equipment operators with the right skills and experience will be in high demand.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Process Equipment Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Process Equipment Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Process Equipment Operators play a crucial role in manufacturing processes that involve chemical reactions or transformations. Their primary responsibilities include:

1. Equipment Operation and Maintenance

Operate and monitor chemical processing equipment, such as reactors, distillation columns, and pipelines.

- Ensure that equipment is operating within prescribed parameters, including temperature, pressure, and flow rates.

- Perform routine maintenance and repairs on equipment to maintain optimal performance.

2. Process Control and Monitoring

Monitor and control chemical processes to ensure they meet quality standards and specifications.

- Collect and analyze process data, such as temperature, pressure, and pH levels.

- Adjust process parameters to optimize production and prevent deviations.

3. Safety and Compliance

Maintain a safe work environment and ensure compliance with health and safety regulations.

- Wear appropriate personal protective equipment (PPE).

- Follow standard operating procedures (SOPs) and emergency protocols.

4. Communication and Teamwork

Collaborate with other operators, technicians, and engineers to ensure a smooth production process.

- Report any equipment issues or process deviations promptly.

- Participate in training and development programs to enhance skills and knowledge.

Interview Tips

To ace the interview for a Chemical Process Equipment Operator position, consider the following preparation tips:

1. Research the Company and Role

Thoroughly research the company’s background, industry, and specific business. Understand the role’s responsibilities and how it aligns with your qualifications.

- Visit the company website and social media pages.

- Read industry news and articles related to the field.

2. Quantify Your Experience and Skills

Quantify your experience and skills whenever possible. Use specific examples and data to demonstrate your contributions to previous roles.

- Highlight your ability to operate and maintain chemical processing equipment, including specific equipment types.

- Provide examples of how you have optimized processes, solved problems, and ensured safety compliance.

3. Practice Answer Common Interview Questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience operating chemical processing equipment.”

- “How do you handle process deviations and ensure product quality?”

- “What are your strengths and weaknesses as a Chemical Process Equipment Operator?”

4. Be Prepared to Discuss Safety and Compliance

Emphasize your commitment to safety and compliance. Provide examples of how you have followed safety protocols and maintained a clean and organized work environment.

- Mention any safety certifications or training you have obtained.

- Discuss your understanding of industry regulations and best practices.

5. Dress Professionally and Arrive On Time

Dress professionally and arrive on time for the interview. This demonstrates respect for the interviewer and organization.

- Choose formal or business casual attire.

- Plan your route and allow for extra time to avoid any traffic or delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Process Equipment Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!