Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Chemical Supervisor interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Chemical Supervisor so you can tailor your answers to impress potential employers.

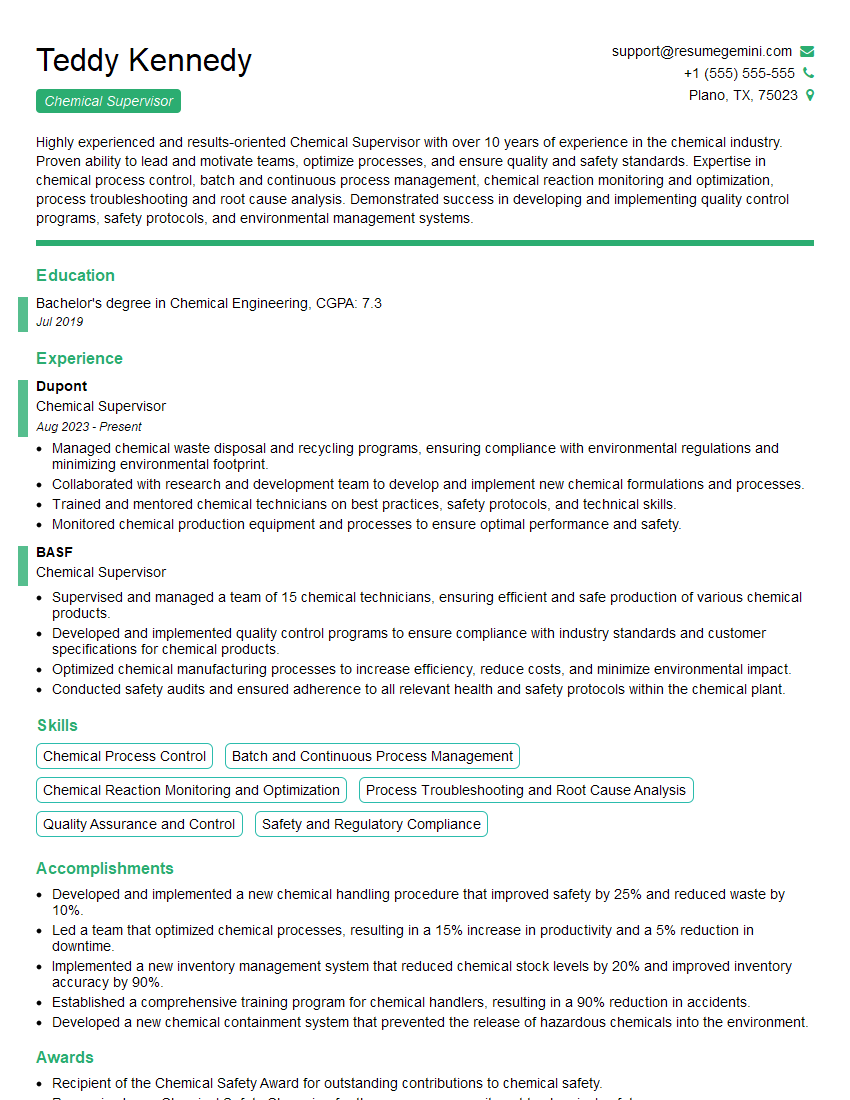

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Supervisor

1. How would you ensure the quality of chemicals used in the production process?

To ensure the quality of chemicals used in the production process, I would implement the following measures:

- Establish and maintain a robust supplier qualification program to assess and approve suppliers based on their quality systems, product specifications, and delivery performance.

- Implement a rigorous incoming inspection process to verify the identity, purity, and quality of all incoming chemicals against established specifications.

- Regularly monitor and evaluate supplier performance through ongoing surveillance audits and data analysis to identify and address any potential quality issues.

- Establish clear acceptance criteria and rejection limits for all chemicals to ensure that only conforming materials are used in production.

- Maintain accurate and up-to-date records of all chemical inspections, test results, and supplier evaluations for traceability and regulatory compliance.

2. Describe the key responsibilities of a Chemical Supervisor.

Technical Responsibilities

- Overseeing the production and handling of chemicals according to established procedures and safety regulations.

- Monitoring and controlling chemical processes to ensure quality, efficiency, and safety.

- Conducting regular inspections of chemical storage, handling, and disposal areas to ensure compliance with regulations.

- Troubleshooting and resolving chemical-related issues and deviations in production.

Management Responsibilities

- Leading and motivating a team of chemical operators and technicians.

- Assigning tasks, providing training, and monitoring performance to ensure productivity and safety.

- Communicating effectively with production, quality control, and other departments to coordinate activities and resolve issues.

- Developing and implementing safety protocols, training programs, and emergency response plans for chemical handling.

3. How would you handle a situation where a chemical spill occurs?

In the event of a chemical spill, I would take the following steps:

- Immediately identify the type and quantity of chemical spilled.

- Alert relevant personnel and evacuate the affected area if necessary.

- Contain the spill using appropriate containment materials such as absorbent pads or booms.

- Neutralize or neutralize the spill using appropriate chemical agents as per established protocols.

- Clean up and dispose of the spilled material and contaminated materials according to safety and environmental regulations.

- Investigate the cause of the spill and implement corrective actions to prevent recurrence.

4. Explain the principles of Good Manufacturing Practices (GMPs) as they relate to chemical production.

GMPs are a set of regulations and guidelines designed to ensure the safety, quality, and consistency of chemical products. In chemical production, GMPs encompass:

- Establishing and maintaining clean and hygienic production environments to prevent contamination.

- Implementing quality control procedures throughout the production process to monitor and ensure product quality.

- Validating and calibrating equipment and instrumentation regularly to ensure accuracy and reliability.

- Training and qualifying personnel in GMP principles and procedures.

- Documenting all production processes, procedures, and inspections to maintain traceability and accountability.

5. How would you prioritize and manage multiple tasks and responsibilities effectively?

To prioritize and manage multiple tasks and responsibilities effectively, I would:

- Use a structured task management system to organize and track tasks.

- Prioritize tasks based on urgency, importance, and impact on production.

- Delegate tasks to team members based on their skills and experience.

- Communicate regularly with team members to ensure coordination and avoid duplication of efforts.

- Monitor progress and adjust priorities as needed to ensure timely completion of all tasks.

6. Describe your experience in managing chemical inventory and ensuring compliance with regulatory requirements.

In my previous role as a Chemical Supervisor, I was responsible for managing a comprehensive chemical inventory system. My responsibilities included:

- Maintaining accurate and up-to-date records of all chemicals, including safety data sheets (SDSs).

- Tracking chemical usage and ensuring compliance with regulatory limits for controlled substances.

- Coordinating with suppliers to ensure timely delivery and proper storage of chemicals.

- Implementing a system for disposing of waste chemicals safely and in accordance with environmental regulations.

7. How would you approach a process optimization project to improve chemical production efficiency?

To approach a process optimization project for improving chemical production efficiency, I would:

- Gather data and analyze current production processes to identify areas for improvement.

- Consult with technical experts and process engineers to develop potential solutions.

- Evaluate and prioritize improvement options based on cost, feasibility, and potential impact.

- Implement the selected improvements and monitor their effectiveness using performance metrics.

- Continuously review and refine the process to maintain optimal efficiency and productivity.

8. Describe your knowledge of chemical safety regulations and how you ensure compliance.

I am well-versed in various chemical safety regulations, including OSHA’s Hazard Communication Standard (HCS), the Toxic Substances Control Act (TSCA), and the Environmental Protection Agency’s (EPA) Resource Conservation and Recovery Act (RCRA).

- To ensure compliance, I:

- Maintain a comprehensive safety program that includes training, hazard assessments, and emergency response plans.

- Provide clear and up-to-date safety instructions to all personnel.

- Enforce the use of personal protective equipment (PPE) and implement proper chemical storage and handling procedures.

- Conduct regular safety inspections and audits to identify and address potential hazards.

- Monitor regulatory updates and implement necessary changes to maintain compliance.

9. How would you motivate and lead a team of chemical operators to achieve production goals?

I believe in empowering my team and fostering a positive and collaborative work environment.

- To motivate and lead my team, I would:

- Set clear expectations and provide regular feedback to encourage continuous improvement.

- Recognize and reward individual and team achievements.

- Create opportunities for professional development and growth.

- Foster open communication and encourage teamwork.

- Lead by example and demonstrate a strong work ethic and commitment to safety and quality.

10. What are your career aspirations and how does this role fit into your long-term goals?

I am passionate about the chemical industry and aspire to grow in a leadership role that allows me to make a significant contribution.

- This role as a Chemical Supervisor aligns with my goals as it:

- Provides a platform to further develop my technical expertise and leadership skills.

- Offers opportunities to drive process improvements and enhance operational efficiency.

- Contributes to the safety and quality of chemical products, which I find both rewarding and impactful.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Chemical Supervisor is responsible for overseeing and managing the activities of a team of chemical operators and ensuring that all chemical processes are carried out safely and efficiently.

1. Supervising and Managing Staff

A Chemical Supervisor is responsible for supervising and managing a team of chemical operators.

- Assign tasks to team members and monitor their progress

- Provide training and support to team members

- Evaluate team members’ performance and provide feedback

2. Ensuring Safety and Compliance

Safety is of paramount importance in any chemical plant. The Chemical Supervisor is responsible for ensuring that all safety regulations are followed at all times.

- Conduct safety inspections and audits

- Investigate accidents and incidents

- Develop and implement safety procedures

- Train staff on safety procedures

3. Managing Production

The Chemical Supervisor is responsible for managing the production process to ensure that products are manufactured to the required specifications and quality standards.

- Develop and implement production schedules

- Monitor production processes and make adjustments as needed

- Ensure that products meet quality standards

- Troubleshoot production problems

4. Maintaining Equipment

The Chemical Supervisor is responsible for maintaining the chemical plant’s equipment to ensure that it is operating efficiently and safely.

- Conduct routine maintenance checks

- Schedule and oversee repairs

- Keep records of maintenance activities

- Troubleshoot equipment problems

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your Chemical Supervisor interview:

1. Do Your Research

Before you go to your interview, it is important to do your research about the company and the position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific questions that you are asked.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work at the company

2. Prepare Your Answers

Once you have done your research, it is time to start preparing your answers to common interview questions. There are a few different ways to do this. You can write out your answers in advance, or you can practice answering them out loud. Either way, it is important to be prepared so that you can answer confidently and clearly.

- Research common interview questions

- Practice answering questions out loud

- Prepare specific examples of your experience

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or other business attire. You should also make sure that your clothes are clean and pressed.

- Wear a suit or other business attire

- Make sure your clothes are clean and pressed

- Give yourself plenty of time to travel to the interview

- Allow for unexpected delays

- Arrive at the interview on time

4. Be on Time

Punctuality is important for any job interview, but it is especially important for a Chemical Supervisor interview. This is because it shows that you are reliable and that you respect the interviewer’s time.

5. Be Confident

Confidence is key in any interview, but it is especially important for a Chemical Supervisor interview. This is because you need to be able to convey to the interviewer that you are capable of leading and managing a team of chemical operators. You should also be able to show that you are confident in your abilities.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Use positive body language

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Chemical Supervisor interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!