Are you gearing up for an interview for a Chemical Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Chemical Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

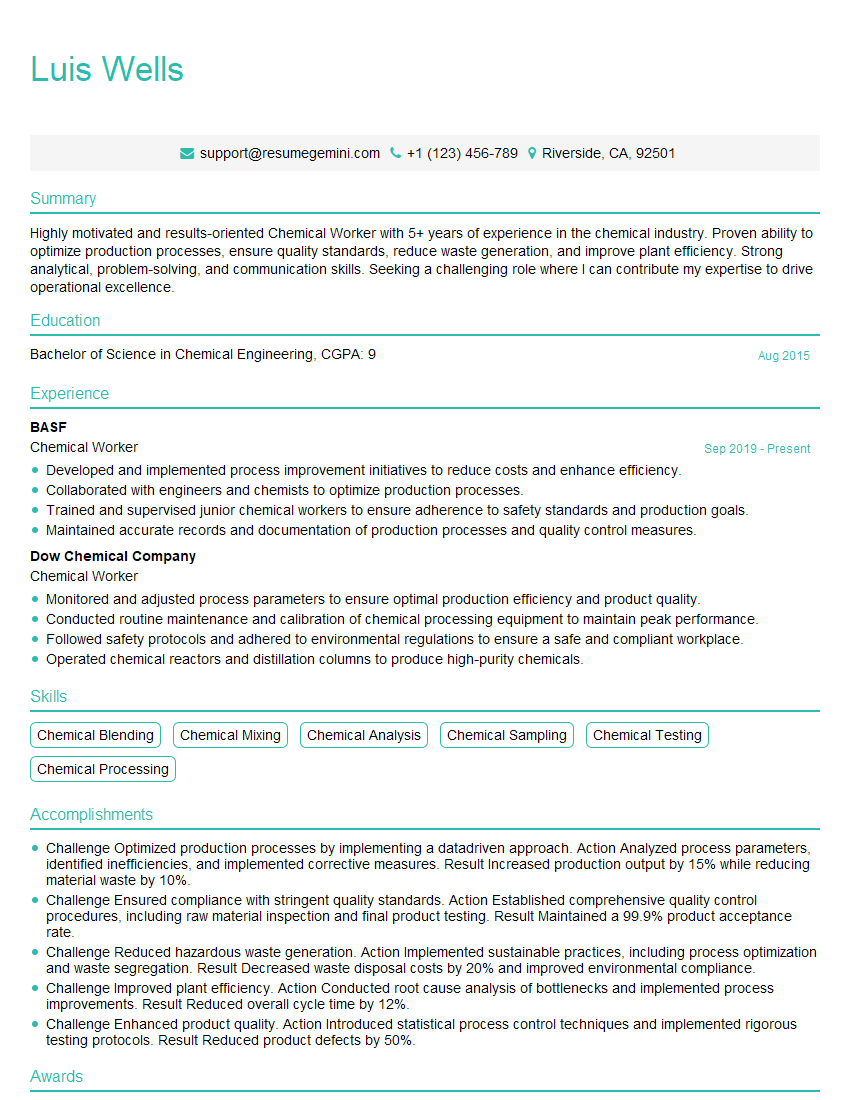

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Chemical Worker

1. Describe the key components of a chemical plant and their functions?

A typical chemical plant consists of the following key components, each with its specific functions:

- Raw material storage: This area stores the raw materials used in the chemical process, such as chemicals, solvents, and gases.

- Reaction vessels: These vessels are used to carry out the chemical reactions required to produce the desired product. They can be of various types, such as batch reactors, continuous reactors, or stirred-tank reactors.

- Separation equipment:

– Distillation columns: Used to separate liquids with different boiling points, such as separating the product from the reaction mixture. – Filters: Used to remove solids from liquids or gases. – Centrifuges: Used to separate solids from liquids based on their density differences. - Product storage: This area stores the finished products before they are packaged and shipped to customers.

- Utilities: This includes the equipment and systems required to provide essential services to the plant, such as electricity, water, steam, compressed air, and cooling systems.

2. What are the common types of chemical reactions used in the industry and how are they monitored?

Types of Chemical Reactions

- Neutralization: Reaction between an acid and a base to form a salt and water.

- Precipitation: Reaction between two soluble ionic compounds to form an insoluble solid precipitate.

- Oxidation-Reduction: Reaction involving the transfer of electrons between species.

- Polymerization: Reaction involving the linking together of multiple monomers to form a polymer.

Monitoring Chemical Reactions

- Temperature Measurement: Using thermocouples or other devices to monitor reaction temperature.

- pH Measurement: Using pH probes to monitor the acidity or basicity of the reaction mixture.

- Conductivity Measurement: Using conductivity probes to monitor the progress of ionic reactions.

- Spectroscopy: Using UV-Vis, IR, or NMR spectroscopy to identify and quantify reactants and products.

- Gas Chromatography: Using gas chromatography to analyze the composition of gas-phase reaction mixtures.

3. How do you ensure the safety of chemical processes and what are the emergency procedures?

- Hazard Identification and Risk Assessment: Identifying potential hazards and assessing the risks associated with them.

- Safe Operating Procedures: Establishing clear and detailed procedures for operating the chemical process safely.

- Engineering Controls: Implementing measures such as interlocks, alarms, and ventilation systems to minimize risks.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE such as gloves, safety glasses, and respirators.

- Emergency Procedures: Developing and implementing emergency procedures for various scenarios, such as spills, fires, and explosions. These procedures include evacuation routes, emergency contacts, and actions to be taken.

- Training and Drills: Providing regular training to employees on safety protocols and conducting drills to ensure preparedness.

4. What are the different types of process control systems used in the chemical industry?

- Manual Control: The process is controlled by human operators.

- Automatic Control: The process is controlled by automated systems using sensors and actuators.

- Computer-Based Control: The process is controlled by computers and software, allowing for more sophisticated control strategies.

- Model Predictive Control: A type of computer-based control that uses mathematical models to predict future process behavior and optimize control actions.

5. What are the challenges in scaling up a chemical process from the lab to a commercial scale?

- Equipment Design: Designing equipment that can handle larger volumes and maintain efficient operation.

- Process Optimization: Adjusting process parameters and conditions to achieve desired production rates and product quality.

- Materials Handling: Ensuring efficient and safe handling of larger quantities of raw materials and products.

- Heat and Mass Transfer: Accounting for changes in heat and mass transfer rates as the process is scaled up.

- Safety Considerations: Addressing safety issues associated with larger-scale production, such as handling hazardous materials and managing larger volumes of waste.

6. Describe the different types of pumps used in the chemical industry and their applications.

- Centrifugal Pumps: Used for high-flow, low-pressure applications.

- Positive Displacement Pumps: Used for low-flow, high-pressure applications.

- Diaphragm Pumps: Used for handling corrosive or abrasive fluids.

- Peristaltic Pumps: Used for precise metering of fluids.

- Magnetic Drive Pumps: Used to prevent contamination from mechanical seals.

7. What are the common troubleshooting techniques used to identify and resolve issues in chemical processes?

- Data Analysis: Analyzing process data to identify deviations and trends.

- Sensory Inspection: Observing the process visually or using sensory cues to detect abnormalities.

- Equipment Checks: Inspecting equipment, such as pumps, valves, and instruments, for malfunctions.

- Process Simulation: Using computer models to simulate the process and identify potential issues.

- Root Cause Analysis: Investigating the underlying causes of process problems to prevent their recurrence.

8. Describe the principles of distillation and its applications in the chemical industry.

Distillation is a separation process that involves the evaporation and condensation of a liquid mixture to separate its components based on their different boiling points:

- Batch Distillation: Used for small-scale production or for separating components with large boiling point differences.

- Continuous Distillation: Used for large-scale production and for separating components with smaller boiling point differences.

- Applications:

- Purification of chemicals

- Production of alcoholic beverages

- Fractionation of petroleum

9. What are the different types of reactors used in the chemical industry and how do you select the appropriate reactor for a specific process?

- Batch Reactors: Used for small-scale production or for reactions requiring close control over process conditions.

- Continuous Reactors: Used for large-scale production and for reactions where continuous feed and product removal are desirable.

- Stirred-Tank Reactors (STR): Used for reactions requiring good mixing and heat transfer.

- Plug Flow Reactors (PFR): Used for reactions where a specific residence time is required.

- Selection Factors:

- Reaction kinetics

- Scale of production

- Process requirements (e.g., temperature, pressure, mixing)

10. What are the key considerations for designing and operating a heat exchanger in the chemical industry?

- Heat Transfer Rate: Determining the required heat transfer area and selecting the appropriate heat exchanger type.

- Materials of Construction: Choosing materials that are compatible with the process fluids and operating conditions.

- Pressure Drop: Minimizing pressure losses in the heat exchanger to maintain process efficiency.

- Fouling and Maintenance: Considering the potential for fouling and implementing measures for cleaning and maintenance.

- Safety: Ensuring the heat exchanger is designed and operated safely to prevent accidents and leaks.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Chemical Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Chemical Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Chemical Workers are responsible for a wide range of tasks in the chemical industry. They may be involved in the production, testing, or packaging of chemicals, or they may work in a laboratory setting. Some of the key job responsibilities of a Chemical Worker include:

1. Operating and Monitoring Equipment

Chemical Workers operate and monitor a variety of equipment, including reactors, distillers, and packaging machines. They ensure that the equipment is functioning properly and that the chemicals are being produced according to specifications.

- Monitoring gauges and dials to ensure that the equipment is operating within safe parameters.

- Adjusting valves and controls to maintain the desired temperature, pressure, and flow rate.

- Taking samples of the chemicals and testing them to ensure that they meet quality standards.

2. Handling and Storing Chemicals

Chemical Workers handle and store a variety of chemicals, including hazardous and flammable materials. They must be familiar with the safe handling and storage procedures for each chemical.

- Wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and respirators.

- Following established procedures for handling and storing chemicals.

- Properly labeling and storing chemicals to prevent contamination or accidents.

3. Cleaning and Maintaining Equipment

Chemical Workers are responsible for cleaning and maintaining the equipment they use. They must ensure that the equipment is clean and free of contamination.

- Cleaning equipment with water, soap, and other cleaning agents.

- Inspecting equipment for damage or wear.

- Performing minor repairs and maintenance tasks.

4. Following Safety Procedures

Chemical Workers must follow all safety procedures to prevent accidents and injuries. They must be aware of the hazards associated with the chemicals they are handling and know how to respond to emergencies.

- Wearing appropriate PPE.

- Knowing the location of the nearest fire extinguisher and eyewash station.

- Being aware of the emergency procedures for the chemicals they are handling.

Interview Tips

Here are some tips to help you ace your interview for a Chemical Worker position:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website to learn about their mission, values, and products.

- Read the job description carefully and identify the key skills and qualifications that the company is looking for.

2. Practice Your Answers to Common Interview Questions

There are some common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

- Brainstorm a list of potential interview questions.

- Write out your answers to these questions and practice saying them out loud.

- Ask a friend or family member to conduct a mock interview with you.

3. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time to show that you are respectful of the interviewer’s time.

- Choose clothing that is clean, pressed, and appropriate for a business setting.

- Plan your route to the interview in advance so that you can avoid getting lost or being late.

4. Be Enthusiastic and Positive

The interviewer wants to know that you are excited about the position and the company. Be enthusiastic and positive throughout the interview, even if you are nervous. This will show the interviewer that you are genuinely interested in the job and that you would be a valuable asset to the team.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and enthusiastic about your skills and experience.

5. Follow Up After the Interview

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are serious about working for the company. You can follow up by sending a thank-you note or email.

- Send a thank-you note to the interviewer within 24 hours of the interview.

- In your thank-you note, reiterate your interest in the position and thank the interviewer for their time.

- If you have any questions about the position or the company, you can also ask them in your thank-you note.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Chemical Worker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.